Novel high-end light thermal insulation partition board and production method thereof

A thermal insulation partition board, high-end technology, used in thermal insulation, walls, other home appliances and other directions, can solve the problems of low compressive strength, unable to meet higher requirements, etc., to achieve the effect of compressive strength reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

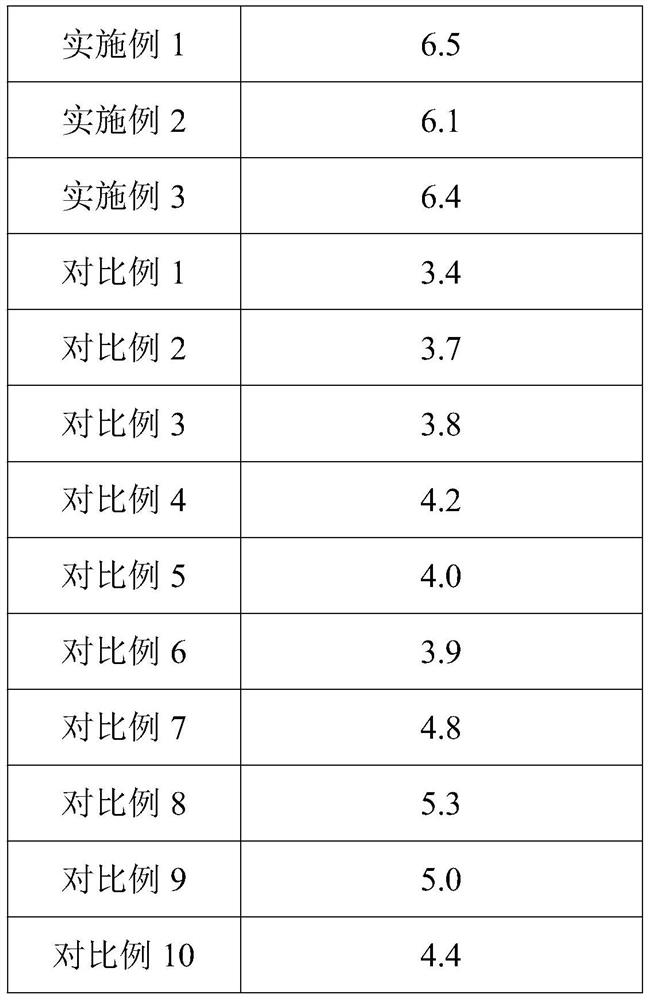

Embodiment 1

[0045] A new type of high-end lightweight insulation partition wall board, including an upper ply and a lower ply, a filling layer is provided between the upper ply and the lower ply, and the filling layer is filled with core materials. In total, the core material includes the following raw materials: 98 parts of cement, 17 parts of ceramsite, 12 parts of gypsum powder, 4 parts of glass fiber, 10 parts of bentonite, 13 parts of mineral powder, 7 parts of potassium aluminum sulfate dodecahydrate, metaluminite 8 parts of sodium bicarbonate, 1.5 parts of water reducer, 0.6 parts of foaming agent, 0.1 part of foam regulator, 0.2 parts of foam stabilizer, 15 parts of hydrogen peroxide, 2.8 parts of diisopropyl peroxydicarbonate, 1 part of cobalt isooctanoate , 4.6 parts of 1,4-cyclohexanediamine, 1.6 parts of 2,2-bis-(tert-butylperoxy)propane, 7 parts of sodium starch octenyl succinate, and 500 parts of water;

[0046] Described cement is portland cement;

[0047] The water reduce...

Embodiment 2

[0061] A new type of high-end lightweight insulation partition wall board, including an upper ply and a lower ply, a filling layer is provided between the upper ply and the lower ply, and the filling layer is filled with core materials. In total, the core material includes the following raw materials: 86 parts of cement, 15 parts of ceramsite, 10 parts of gypsum powder, 3 parts of glass fiber, 7 parts of bentonite, 10 parts of mineral powder, 4 parts of potassium aluminum sulfate dodecahydrate, partial aluminum 5 parts sodium bicarbonate, 1.2 parts water reducer, 0.4 parts foaming agent, 0.1 parts foam regulator, 0.2 parts foam stabilizer, 13 parts hydrogen peroxide, 2.2 parts diisopropyl peroxydicarbonate, 0.8 parts cobalt isooctanoate , 3.6 parts of 1,4-cyclohexanediamine, 1.2 parts of 2,2-bis-(tert-butylperoxy)propane, 6.2 parts of sodium starch octenyl succinate, 430 parts of water;

[0062] Described cement is portland cement;

[0063] The water reducer is TH-928 polycar...

Embodiment 3

[0077] A new type of high-end lightweight insulation partition wall board, including an upper ply and a lower ply, a filling layer is provided between the upper ply and the lower ply, and the filling layer is filled with core materials. In total, the core material includes the following raw materials: 110 parts of cement, 19 parts of ceramsite, 13 parts of gypsum powder, 5 parts of glass fiber, 11 parts of bentonite, 16 parts of mineral powder, 7 parts of potassium aluminum sulfate dodecahydrate, metaluminite 9 parts of sodium bicarbonate, 1.6 parts of water reducer, 0.7 parts of foaming agent, 0.2 parts of foam regulator, 0.3 parts of foam stabilizer, 15 parts of hydrogen peroxide, 3 parts of diisopropyl peroxydicarbonate, 1.1 parts of cobalt isooctanoate , 5.6 parts of 1,4-cyclohexanediamine, 1.7 parts of 2,2-bis-(tert-butylperoxy)propane, 7.6 parts of sodium starch octenyl succinate, and 580 parts of water;

[0078] Described cement is portland cement;

[0079] The water r...

PUM

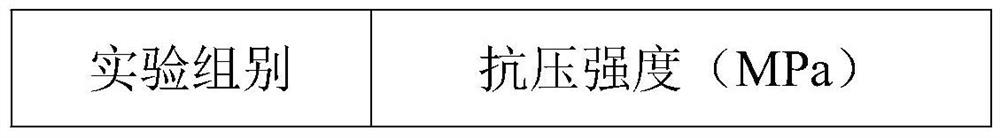

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com