High-performance lithium-calcium-tantalum-nickel-zinc-niobium-magnesium-tungsten modified PZT piezoelectric ceramic prepared at low temperature

A piezoelectric ceramic, high-performance technology, applied in the field of piezoelectric ceramic materials, can solve the problems of ceramic electrical performance deterioration, affecting the reliability of multi-layer devices, etc., to achieve the effect of improving crystal grains, good piezoelectric performance, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 6

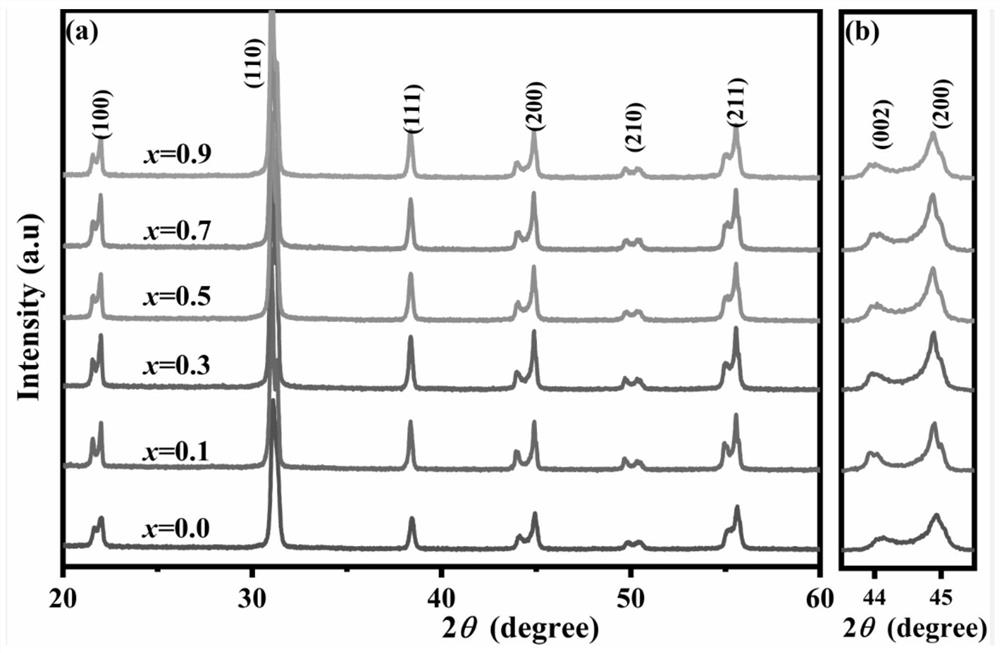

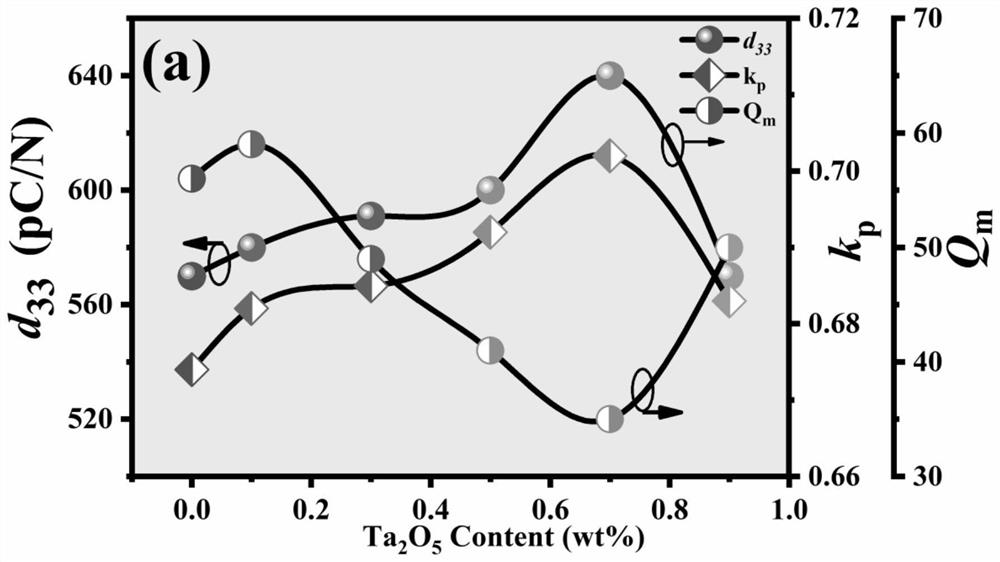

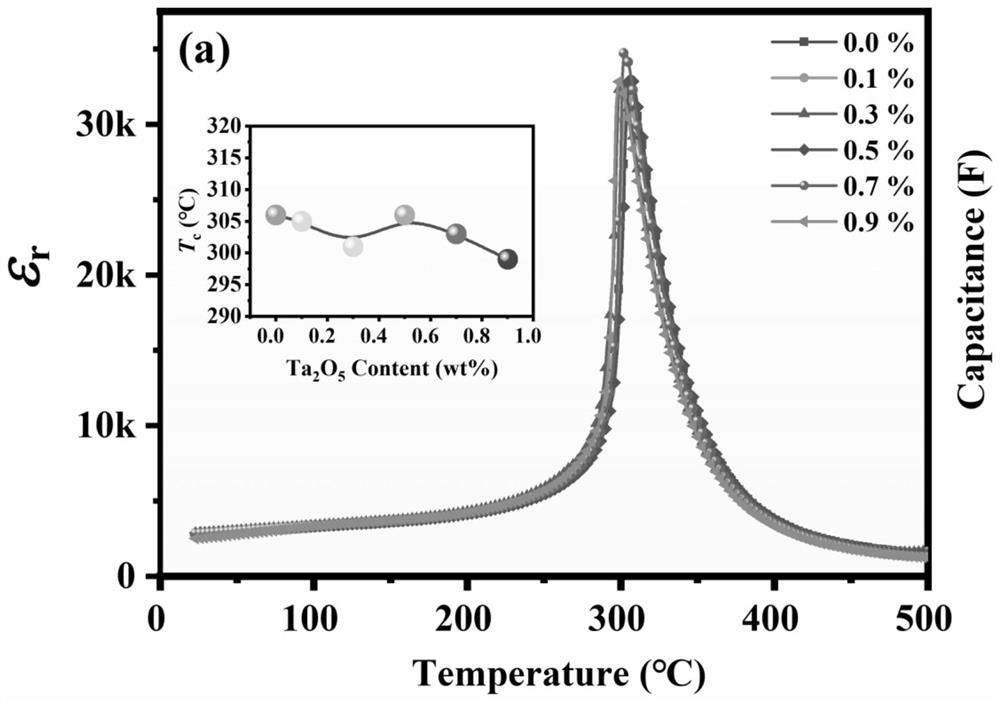

[0029] The XRD pattern of the high-performance PZT modified piezoelectric ceramics prepared at low temperature is shown in figure 1 , figure 1 It shows that the PZT modified piezoelectric ceramic is a pure perovskite phase; the ZJ-3 quasi-static d 33 meter, the measured piezoelectric coefficient d 33 See figure 2 , is 570pC / N; use Agilent 4980A precision impedance meter to connect temperature control furnace to measure the change of dielectric constant with temperature, which can be obtained from image 3 The Curie temperature of the obtained sample was 299°C.

[0030] Example 7

[0031] Example 8

Embodiment 2

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Piezoelectric coefficient | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

| Piezoelectric coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com