Solid-waste-based cementing material for treating pyrite slag and use method of solid-waste-based cementing material

A technology of pyrite slag and a treatment method, which is applied in the field of environmental restoration, can solve problems such as polluting the environment of a mining area, and achieve the effects of reducing the amount of engineering, safe treatment, and solving the risk of an anti-seepage structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The pyrite slag samples were divided into experimental group, control group 1 and control group 2. Among them,

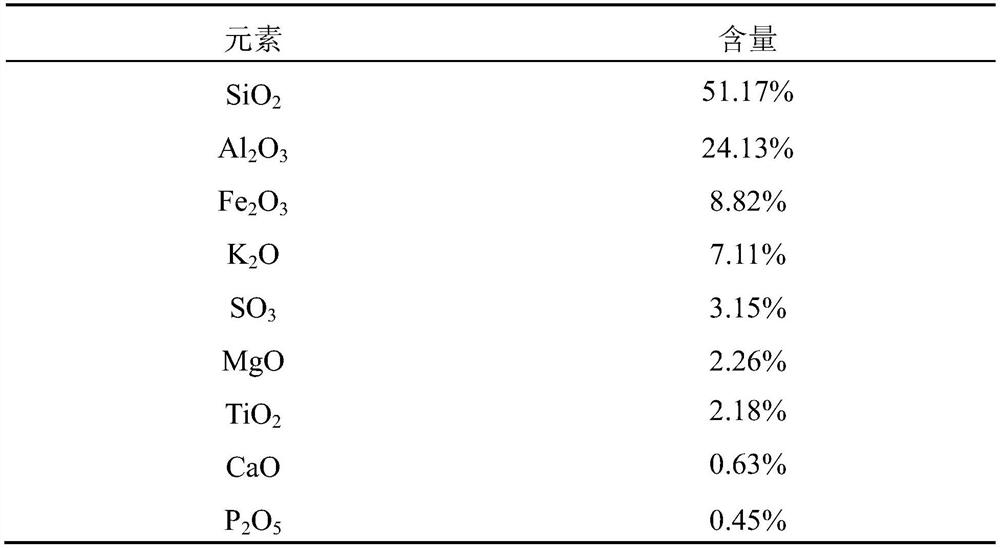

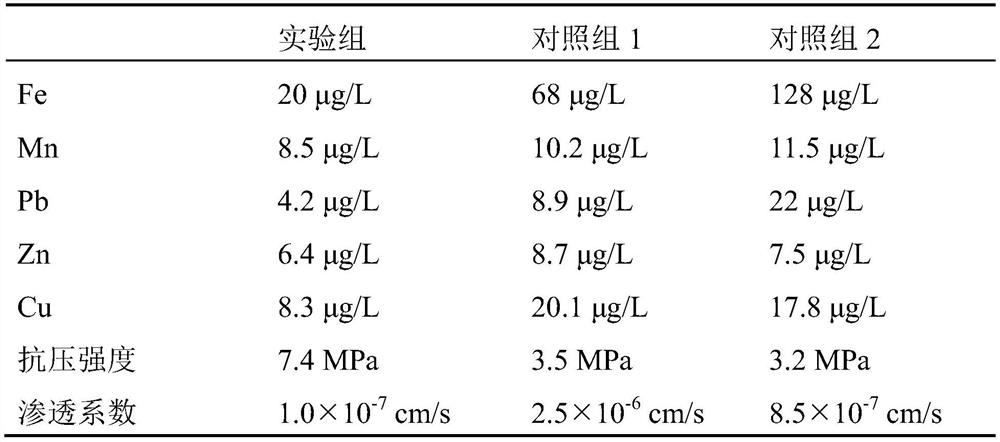

[0043] Experimental group: solid waste-based cementitious materials were prepared, including 35% slag, 28% desulfurization gypsum, 16% steel slag, 10% red mud, 7% manganese sand and 4% zeolite. Among them, the slag quality coefficient K=1.4, the desulfurization gypsum contains 95% CaSO 4 , The steel slag contains 50% CaO, the red mud contains 45% CaO, the manganese sand contains 45% MnO, and the zeolite purity is 90%. The pyrite slag and the above-mentioned solid waste-based cementitious material are fully mixed according to a ratio of 5:1, and 40% of the water is added, and the mold is put into compression molding and maintained for 24 days. HJ / T299-2007) in the weak acid environment to detect the heavy metal leaching, compressive strength and permeability coefficient of the consolidated body. The test results are shown in Table 2 below.

[0044] Control ...

Embodiment 2

[0050] The present embodiment provides a method for treating pyrite slag, comprising the following steps:

[0051] (1) Preparation of solid waste-based cementitious materials, including: 35% slag, 28% desulfurization gypsum, 16% steel slag, 10% red mud, 7% manganese sand and 4% zeolite. Among them, the slag quality coefficient K=1.4, the desulfurization gypsum contains 95% CaSO 4 , The steel slag contains 50% CaO, the red mud contains 45% CaO, the manganese sand contains 45% MnO, and the zeolite purity is 90%.

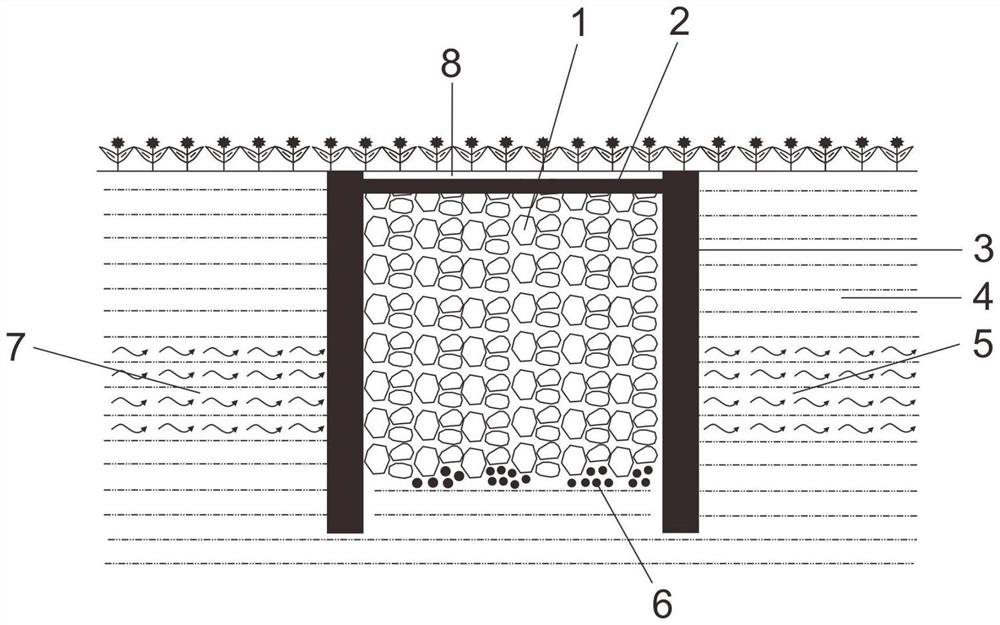

[0052] (2) Excavate the pyrite slag with a thickness of 50 cm on the top of the pyrite slag, and lay HDPE anti-seepage film at the bottom of the formed pit, and then mix the excavated pyrite slag with the solid waste-based cementitious material at a ratio of 5:1 Mix in the proportion of 40% water, and toss until the mixture is uniform in color.

[0053] (3) Backfill the mixture into the pit at the top of the pyrite slag pile, and use a press to press the mixture into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com