Textile fabric desizing equipment

A technology for desizing equipment and textile fabrics, which is applied in the directions of equipment configuration for processing textile materials, processing of textile materials, continuous processing of textile materials, etc., to achieve the effects of convenient operation, improved effect, and simple use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

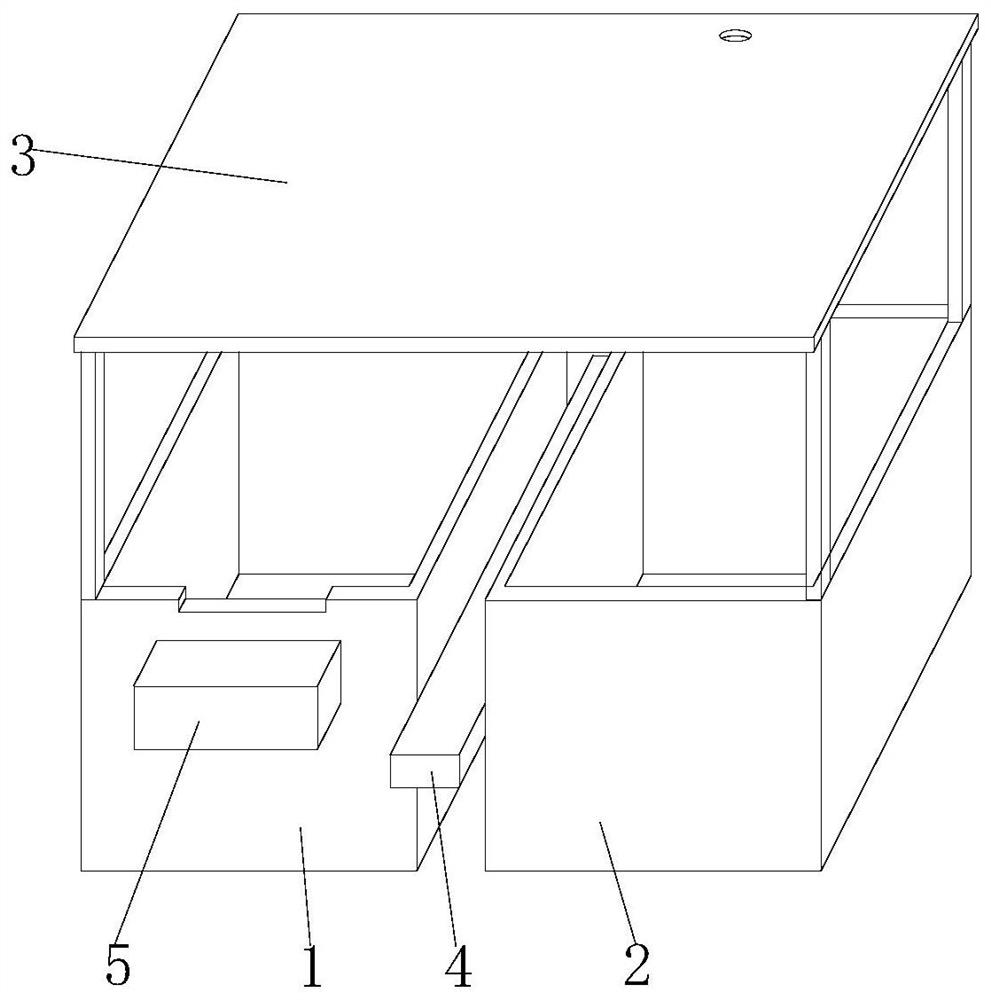

Embodiment 1

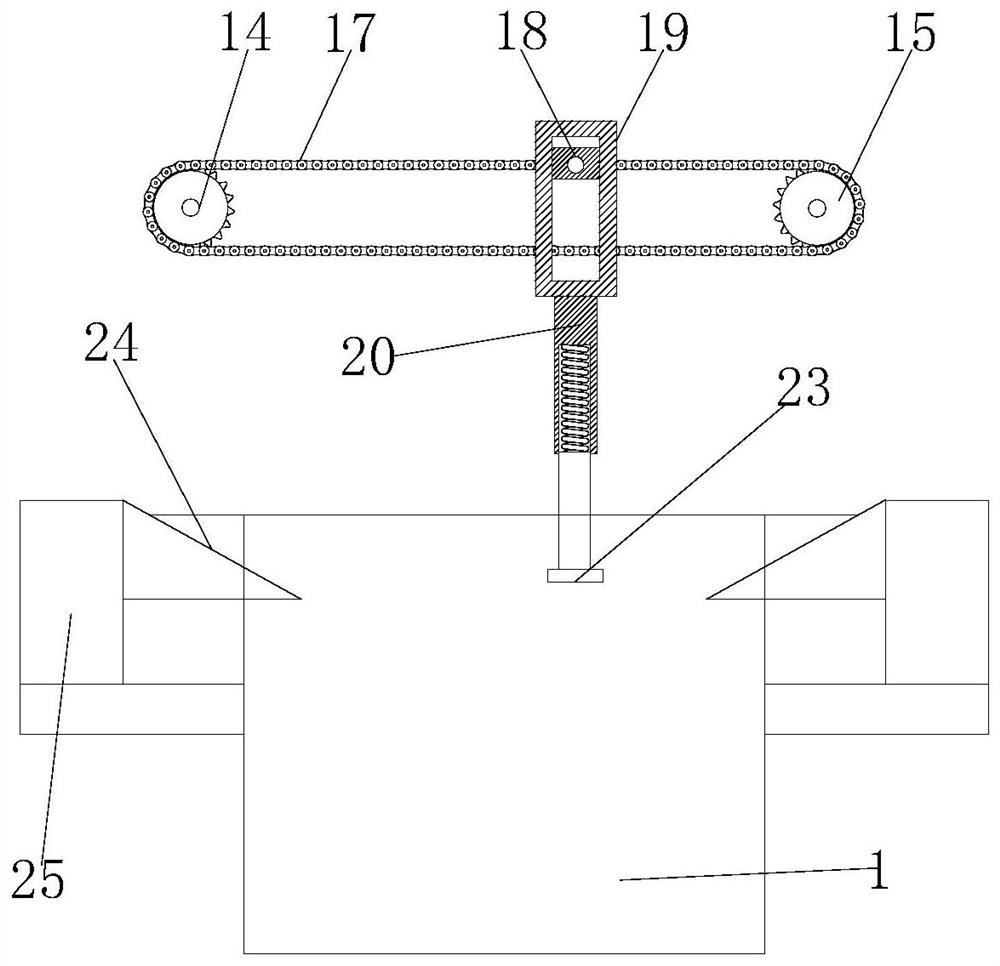

[0027] In the present invention, a rotating shaft is rotatably installed on the bracket 3, and the rotating shaft is fixedly connected with the second pulley 27, and the rotating shaft can make the second pulley 27 rotate at a fixed position.

[0028] In the present invention, the bracket 3 is provided with a bearing, the inner ring of the bearing is fixedly connected with the rotating rod 13, and the bearing can make the rotating rod 13 rotate at a fixed position.

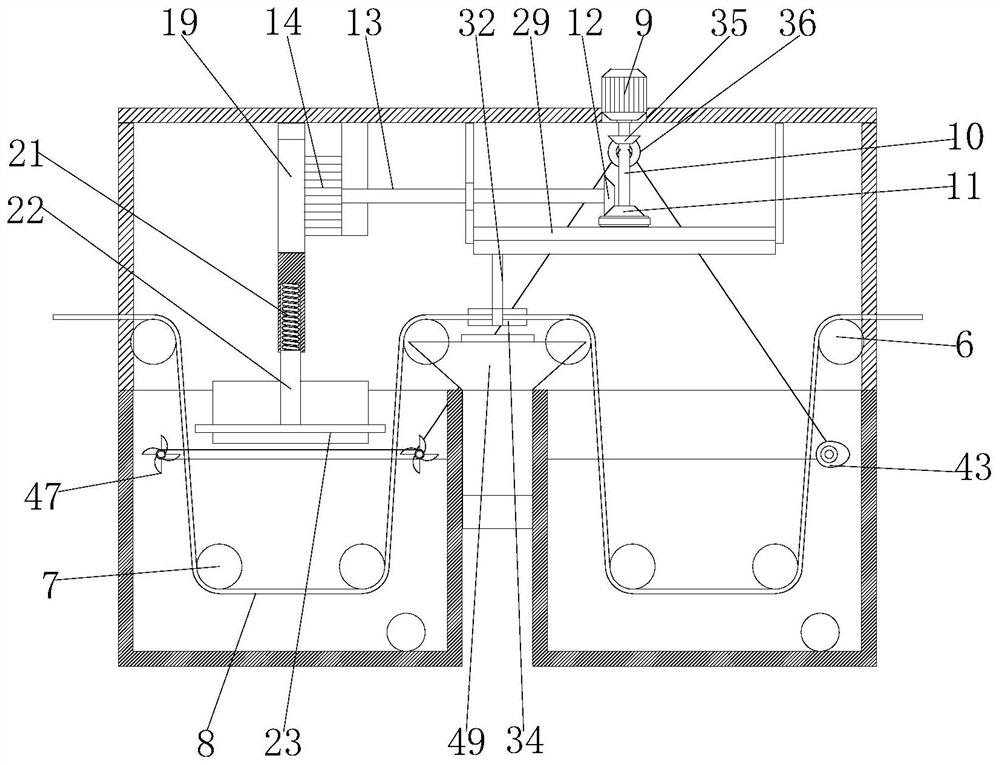

[0029] Working principle: when in use, the desizing fabric 8 is passed through multiple feeding rollers 6 and auxiliary rollers 7, the desizing tank 1 is injected with the desizing solution, and the clear water tank 2 is injected with clean water to start desizing. The feeding roller 6 drives the desized fabric 8 after desizing to move, turns on the motor 9, and then drives the rotating rod 10 to rotate, and the rotating rod 10 rotates, and then drives the first bevel gear 11, the third bevel gear 35 and the first pu...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com