Combined grinding device for rotating surface and adjacent surface of metal workpiece

A metal workpiece and adjacent surface technology, which is applied to machine tools, grinding drives, and metal processing equipment designed for grinding the rotating surface of workpieces, to achieve flexible and ingenious processing, ensure concentric positioning, and simple and convenient installation.

Inactive Publication Date: 2022-06-10

艾芦精密机械(江苏)有限公司

View PDF15 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003]However, as far as the current metal workpiece grinding device is concerned, it is impossible to realize multi-working surface linkage grinding, the work efficiency is low, and it is not convenient for the staff to operate. The grinding device generates waste and increases the processing cost. At the same time, the secondary positioning error is large, which reduces the processing effect and cannot realize the linkage grinding. The structure is complicated and the cost is high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

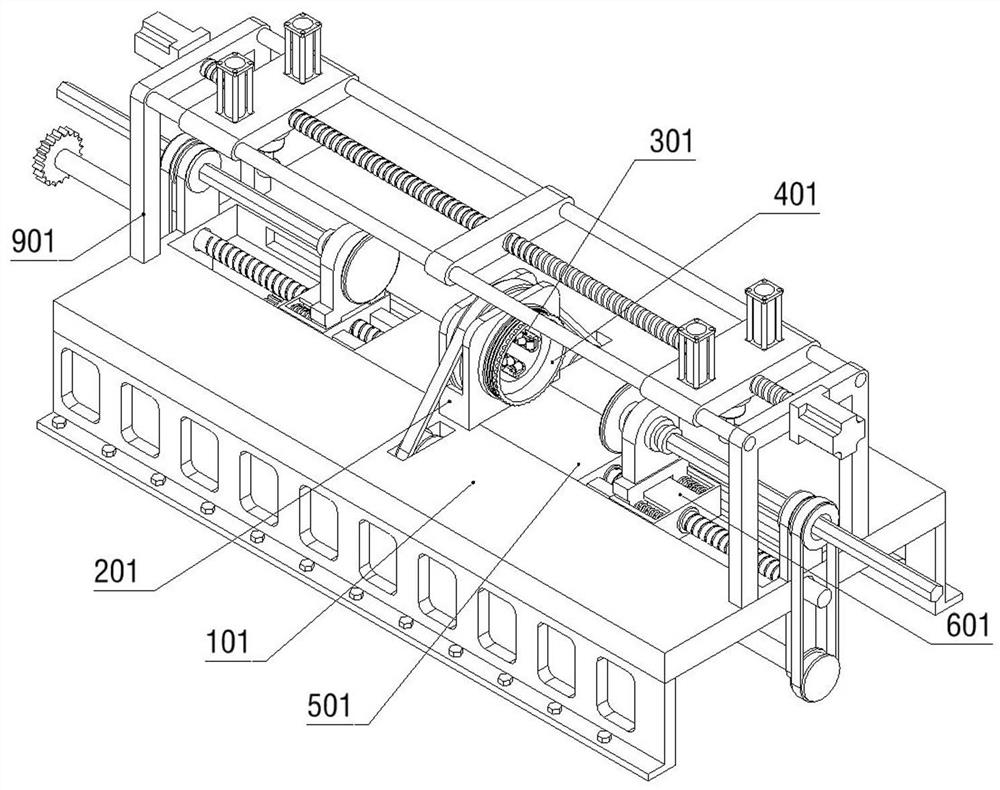

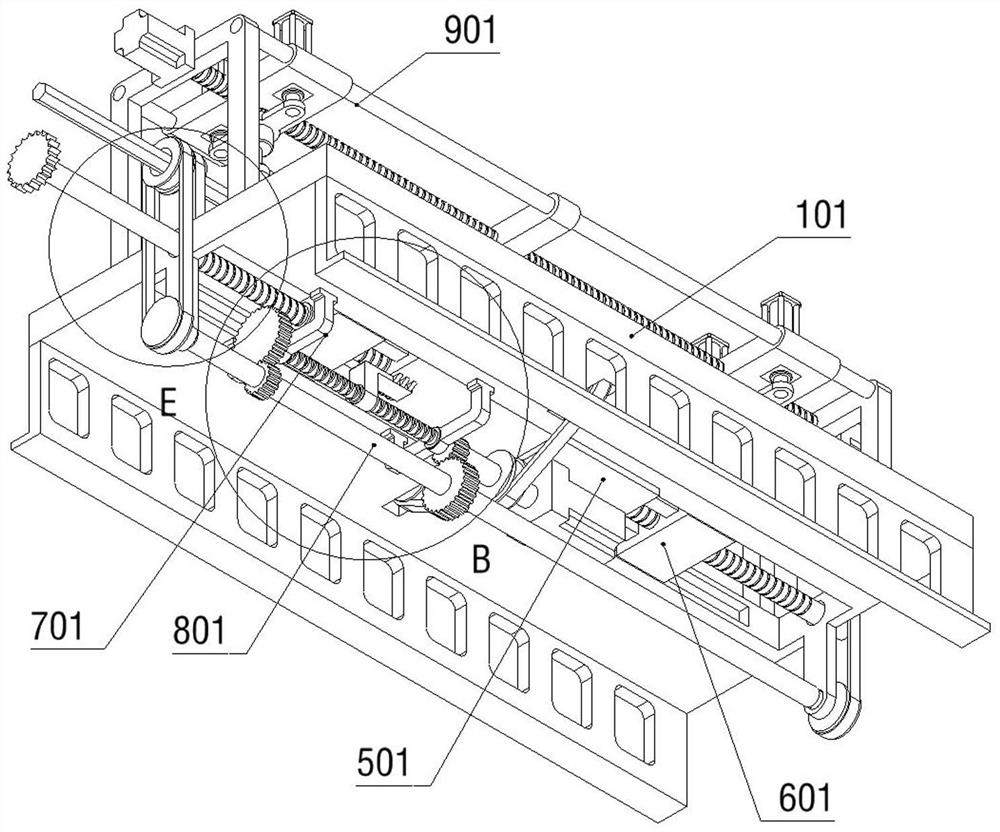

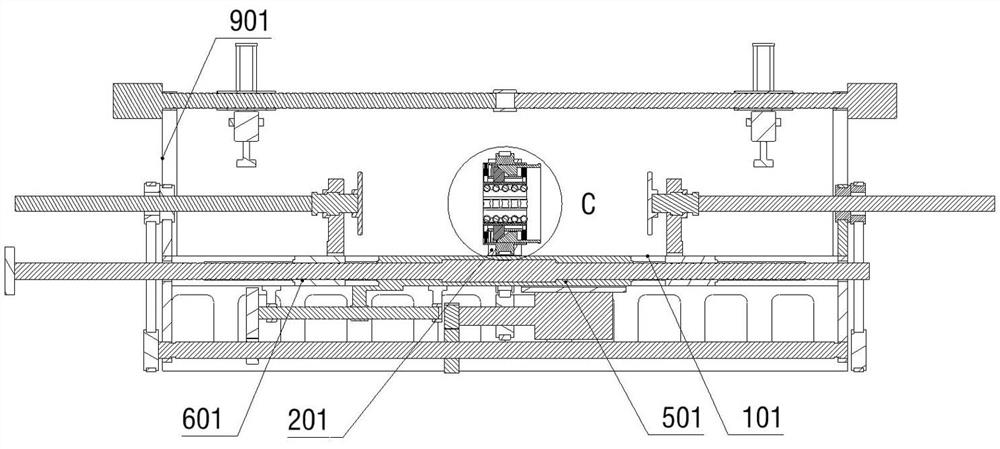

The invention provides a combined grinding device for a rotating surface and an adjacent surface of a metal workpiece, and relates to the technical field of metal processing. Four sliding positioning devices are connected to the operation mounting part in a sliding manner; the four sliding positioning devices are mounted on the inner side of the operation mounting part in an annular array; the operation mounting part is in threaded connection with a positioning driving piece; a movable expansion device is slidably connected to the supporting device; adjacent surface grinding devices are mounted on the two sides of the movable expansion device respectively; the bottom of the supporting device is fixedly connected with a reciprocating driving device; comprehensive combined grinding can be achieved, the machining precision is improved, one-time positioning forming can be achieved, and errors are smaller; the problems that according to an existing metal workpiece grinding device, multi-working-face linkage grinding cannot be achieved, a slidable grinding device is not arranged, the machining cost is greatly increased, the structure is complex, and the manufacturing cost is high are solved.

Description

technical field [0001] The invention relates to the technical field of metal processing, in particular to a combined grinding device for a rotating surface and an adjacent surface of a metal workpiece. Background technique [0002] In the actual metal processing process, metal grinding is one of the most commonly used processing methods because it involves the quality of the processed product and processing efficiency. At this time, a good combined grinding device for the rotating surface and the adjacent surface of the metal workpiece is appears to be particularly important. [0003] However, as far as the current metal workpiece grinding device is concerned, it is impossible to realize multi-working surface linkage grinding, and the work efficiency is low. At the same time, it is not convenient for the staff to operate. There is no sliding grinding device, which generates waste and increases processing costs. At the same time, the secondary positioning error Large, reduci...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B24B5/01B24B27/00B24B45/00B24B41/06B24B47/20B24B47/12

CPCB24B5/01B24B27/0076B24B45/003B24B41/067B24B47/20B24B47/12

Inventor 岡田泰元岸健一中上静李欣菅野衛

Owner 艾芦精密机械(江苏)有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com