High-quality silicon nitride medium passivation layer treatment process based on supercritical fluid

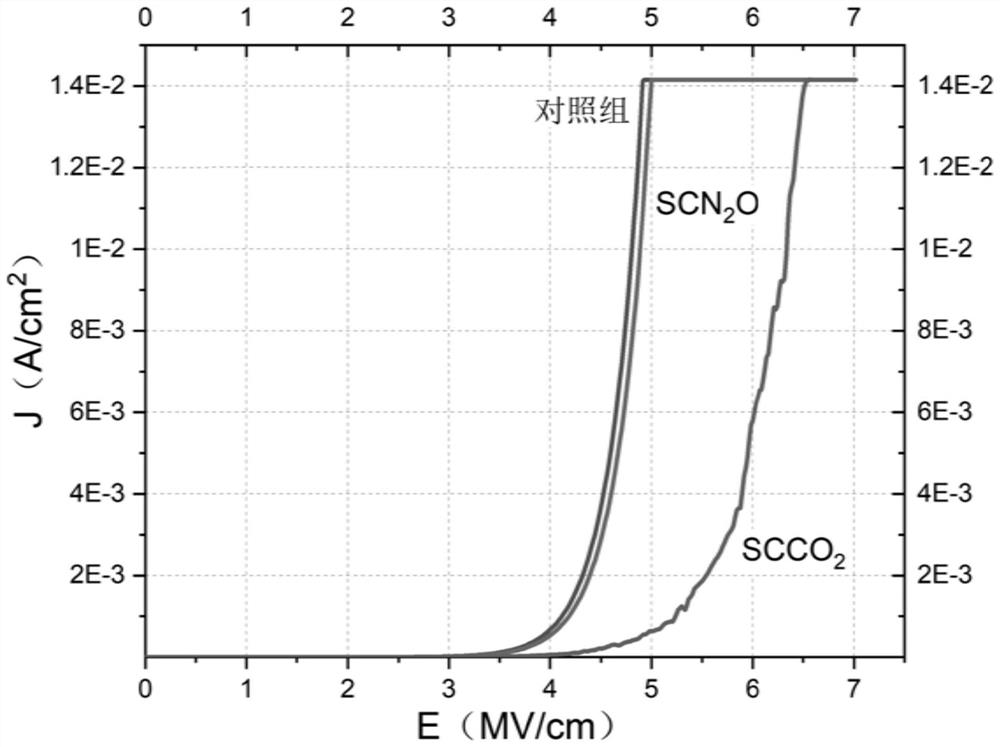

A technology of supercritical fluid and processing technology, which is applied in the production of bulk chemicals, semiconductor/solid-state device manufacturing, electrical components, etc. It can solve the problems of low breakdown field strength, high leakage current, and high interface state density to improve quality , Improve the breakdown electric field, and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

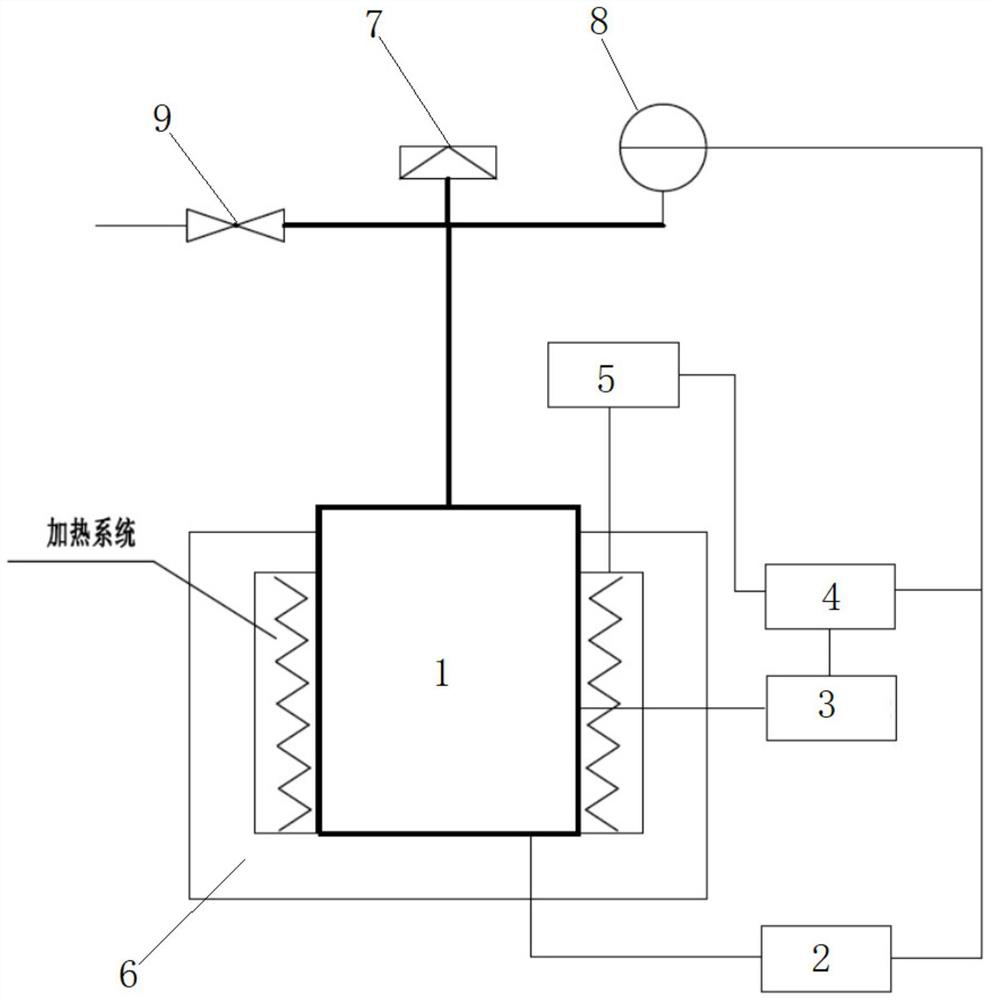

Method used

Image

Examples

Embodiment 1

[0070] S1, will have Si 3 N 4 The substrate sample of the dielectric layer is placed on the support inside the supercritical equipment to ensure that the substrate sample is vertical;

[0071] S2. Fill the chamber of the supercritical equipment with 0.5 mL of deionized water, and then seal the supercritical equipment;

[0072] S3. The initial pressure is 10MPa and the control pressure is 15MPa, and CO is charged into the supercritical equipment. 2 supercritical gas;

[0073] S4, control the heating rate to be 1 ℃ for 1 min, increase the temperature of the supercritical equipment from 25 ℃ to 120 ℃, increase the pressure of the supercritical equipment to 15 MPa, and then maintain the pressure for 1 min;

[0074] S5, maintaining the supercritical state treatment in step S4, at 120 ° C, depressurizing treatment and maintaining the time under the supercritical treatment condition of 20MPa for 1h;

[0075] S6. After the reaction in step S5, when the temperature of the reactor i...

Embodiment 2

[0078] S1, will have Si 3 N 4 The substrate sample of the dielectric layer is placed on the support inside the supercritical equipment to ensure that the substrate sample is vertical;

[0079] S2. Fill the chamber of the supercritical equipment with 0.7 mL of deionized water, and then seal the supercritical equipment;

[0080] S3. The initial pressure is 11MPa and the control pressure is 25MPa, and CO is charged into the supercritical equipment. 2 supercritical gas;

[0081] S4, control the heating rate to be 2℃ for 1min, increase the temperature of the supercritical equipment from 25℃ to 125℃, increase the pressure of the supercritical equipment to 20MPa, and then keep the pressure for 20min;

[0082] S5, maintaining the supercritical state treatment in step S4, at 125 ° C, depressurizing treatment and maintaining the time under the supercritical treatment condition of 20MPa for 1.2h;

[0083] S6. After the reaction in step S5, when the temperature of the reactor is lower...

Embodiment 3

[0086] S1, will have Si 3 N 4 The substrate sample of the dielectric layer is placed on the support inside the supercritical equipment to ensure that the substrate sample is vertical;

[0087] S2. Fill the chamber of the supercritical equipment with 0.9 mL of deionized water, and then seal the supercritical equipment;

[0088] S3. The initial pressure is 11MPa and the control pressure is 35MPa, and N is charged into the supercritical equipment. 2 O supercritical gas;

[0089] S4, control the heating rate to be 4℃ for 1min, increase the temperature of the supercritical equipment from 25℃ to 130℃, increase the pressure of the supercritical equipment to 25MPa, and then keep the pressure for 30min;

[0090] S5, maintaining the supercritical state treatment in step S4, at 130° C., depressurizing treatment and maintaining the time under the supercritical treatment condition of 21MPa for 1.3h;

[0091] S6. After the reaction in step S5, when the temperature of the reactor is lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakdown electric field | aaaaa | aaaaa |

| Leakage current density | aaaaa | aaaaa |

| Breakdown electric field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com