Wetting dispersant for water-based paint and preparation method of wetting dispersant

A technology for wetting and dispersing agents and water-based coatings, which is applied in the field of wetting and dispersing agents for water-based coatings and its preparation, can solve the problems of inconspicuous dispersion effects, and achieve the effects of improving dispersibility and improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

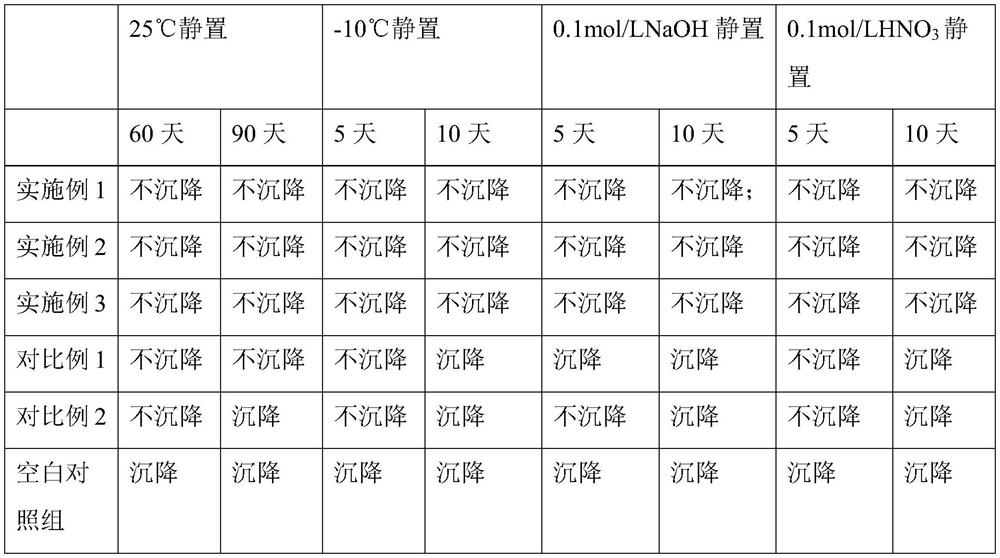

Embodiment 1

[0027] A wetting and dispersing additive for waterborne coatings, comprising the following components:

[0028] The modified polymer dispersant with a mass fraction of 36% and the fatty acid diethanolamine with a mass fraction of 0.8%, and the rest are water.

[0029] A preparation method of wetting and dispersing agent for water-based paint, comprising the following steps:

[0030] The wetting and dispersing agent for water-washing paint can be obtained by stirring and mixing the modified polymer dispersant with a mass fraction of 36%, fatty acid diethanolamine with a mass fraction of 0.8%, and the rest of water.

[0031] Wherein, the preparation process of the modified polymer dispersant is as follows:

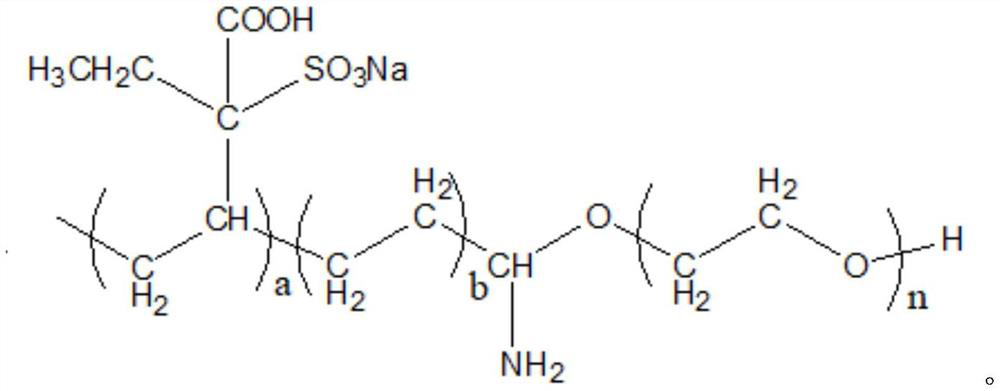

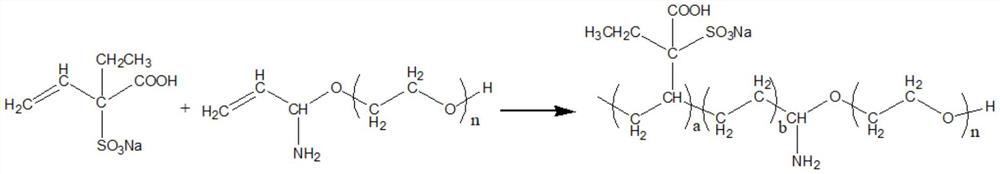

[0032] Put the polyoxyethylene ether molecular monomer with amino group in the reaction kettle, heat it to melt, then add the aqueous solution of the carboxylic acid monomer with sulfonic acid base prepared in advance to it, and simultaneously put in Na 2 S 2 O 8 Initiat...

Embodiment 2

[0034] A wetting and dispersing additive for waterborne coatings, comprising the following components:

[0035] The modified polymer dispersant with a mass fraction of 45% and the fatty acid diethanolamine with a mass fraction of 1.2%, and the rest are water.

[0036] A preparation method of wetting and dispersing agent for water-based paint, comprising the following steps:

[0037] The wetting and dispersing agent for water-wash paint can be obtained by stirring and mixing the modified polymer dispersant with a mass fraction of 45%, fatty acid diethanolamine with a mass fraction of 1.2%, and the rest of water.

[0038] Wherein, the preparation process of the modified polymer dispersant is as follows:

[0039] Put the polyoxyethylene ether molecular monomer with amino group in the reaction kettle, heat it to melt, then add the aqueous solution of the carboxylic acid monomer with sulfonic acid base prepared in advance to it, and simultaneously put in Na 2 S 2 O 8 Initiator,...

Embodiment 3

[0041] A wetting and dispersing additive for waterborne coatings, comprising the following components:

[0042] The modified polymer dispersant with a mass fraction of 56% and a fatty acid diethanolamine with a mass fraction of 1.5%, and the rest are water.

[0043] A preparation method of wetting and dispersing agent for water-based paint, comprising the following steps:

[0044] The wetting and dispersing agent for water-washed paint can be obtained by stirring and mixing the modified polymer dispersant with a mass fraction of 56%, fatty acid diethanolamine with a mass fraction of 1.5%, and the rest of water.

[0045] Wherein, the preparation process of the modified polymer dispersant is as follows:

[0046] Put the polyoxyethylene ether molecular monomer with amino group in the reaction kettle, heat it to melt, then add the aqueous solution of the carboxylic acid monomer with sulfonic acid base prepared in advance to it, and simultaneously put in Na 2 S 2 O 8 Initiator, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com