Composite current collector and preparation method thereof

A technology for current collectors and substrates, applied in electrode current collector coating, electrode manufacturing, electrode carrier/current collectors, etc. Peeling force, enhancing the peeling force of the pole piece, reducing the effect of internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

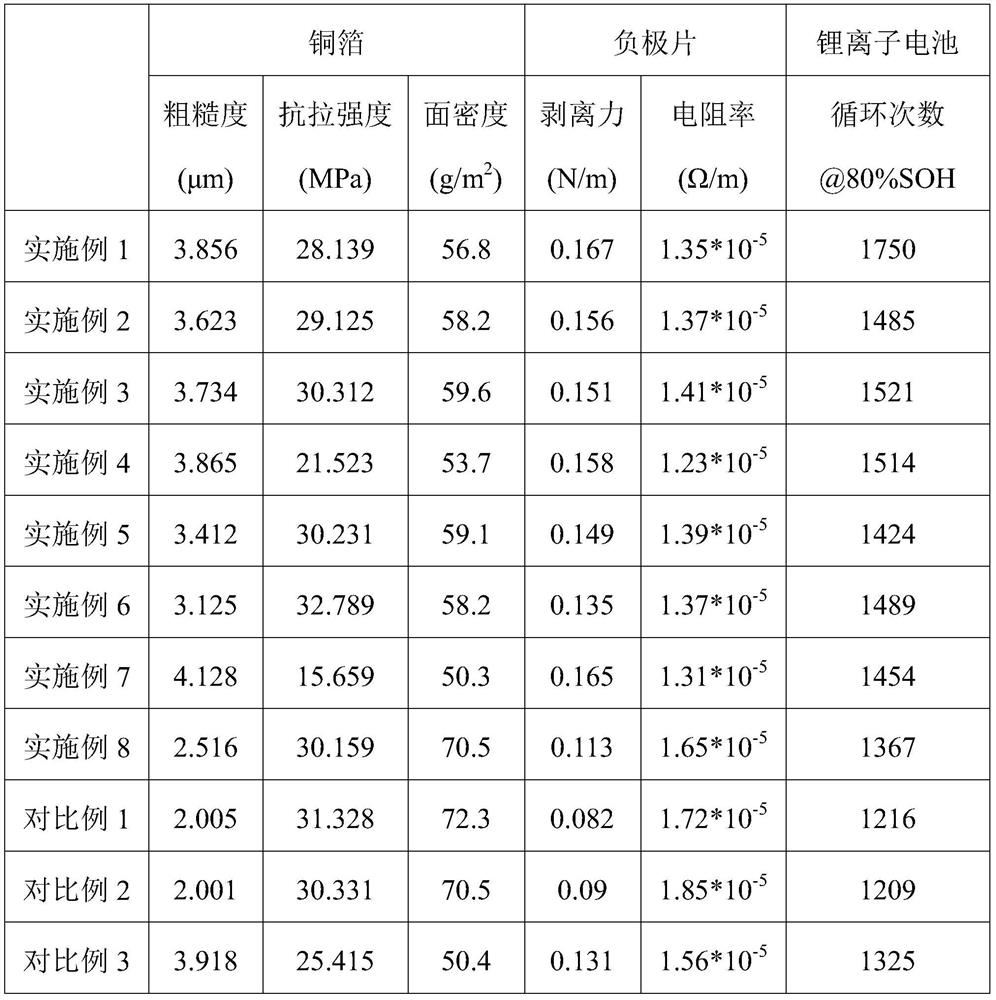

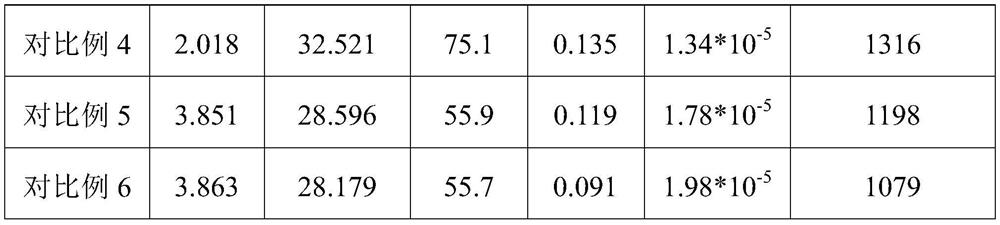

Examples

Embodiment 1

[0051] This embodiment provides a composite current collector and a preparation method thereof. The composite current collector includes an etched copper foil containing hydroxyl groups on the surface and a modified adhesive layer disposed on one surface of the etched copper foil. The thickness of the binder layer is 1.5 μm, and the modified binder layer includes a modified binder LA136S1 containing hydroxyl and carboxyl groups on the surface.

[0052] The present embodiment also provides a preparation method of the above-mentioned composite current collector, including:

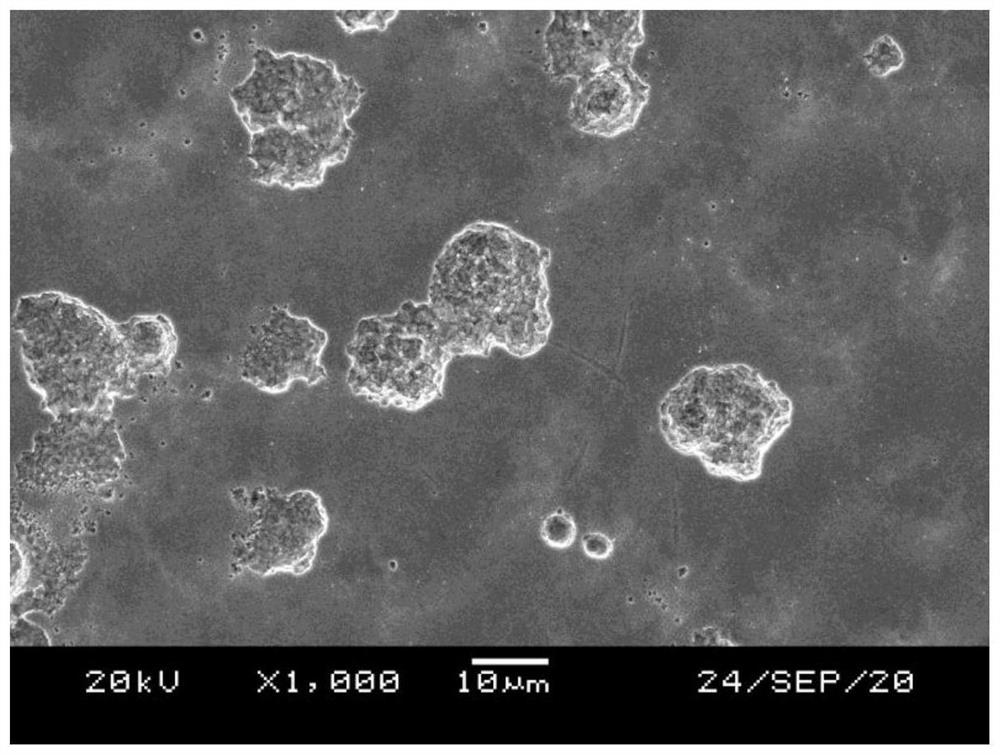

[0053] (1) Preparation of etched copper foil: Take copper foil with a thickness of 8 μm, ultrasonically clean it with acetone, absolute ethanol, and deionized water in turn to remove the oil film on the surface, and then dry the copper foil naturally at room temperature; configure the volume ratio A mixture of 1:1 sodium persulfate and ammonia water was used as the etching solution, and the copper foil after...

Embodiment 2

[0060] This embodiment provides a composite current collector and a preparation method thereof. The composite current collector includes an etched copper foil containing hydroxyl groups on the surface and a modified adhesive layer disposed on one surface of the etched copper foil. The thickness of the binder layer is 2 μm, and the modified binder layer includes a modified binder LA136S1 containing hydroxyl and carboxyl groups on the surface.

[0061] The present embodiment also provides a preparation method of the above-mentioned composite current collector, including:

[0062] (1) Preparation of etched copper foil: Take a copper foil with a thickness of 7 μm, ultrasonically clean it with acetone, anhydrous ethanol, and deionized water in turn to remove the oil film on the surface, and then dry the copper foil naturally at room temperature; configure the volume ratio A mixture of 1:1 sodium persulfate and ammonia water was used as the etching solution, and the copper foil afte...

Embodiment 3

[0069] This embodiment provides a composite current collector and a preparation method thereof. The composite current collector includes an etched copper foil containing hydroxyl groups on the surface and a modified adhesive layer disposed on one surface of the etched copper foil. The thickness of the binder layer is 1 μm, and the modified binder layer includes a modified binder LA136S1 containing hydroxyl and carboxyl groups on the surface.

[0070] The present embodiment also provides a preparation method of the above-mentioned composite current collector, including:

[0071] (1) Preparation of etched copper foil: Take copper foil with a thickness of 9 μm, ultrasonically clean it with acetone, anhydrous ethanol, and deionized water in turn to remove the oil film on the surface, and then dry the copper foil naturally at room temperature; configure the volume ratio A mixture of 1:1 sodium persulfate and ammonia water was used as the etching solution, and the copper foil after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com