Heat conducting flame-retardant control cable

A technology for control cables and insulating layers, applied in the field of thermally conductive and flame-retardant control cables, can solve problems such as burning of insulating layers, difficulty in ensuring work safety and reliability, and affecting the normal operation of control cables, and achieve good thermal conductivity, enhanced thermal conductivity, and improved thermal conductivity. The effect of good flame retardant performance, thermal conductivity and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

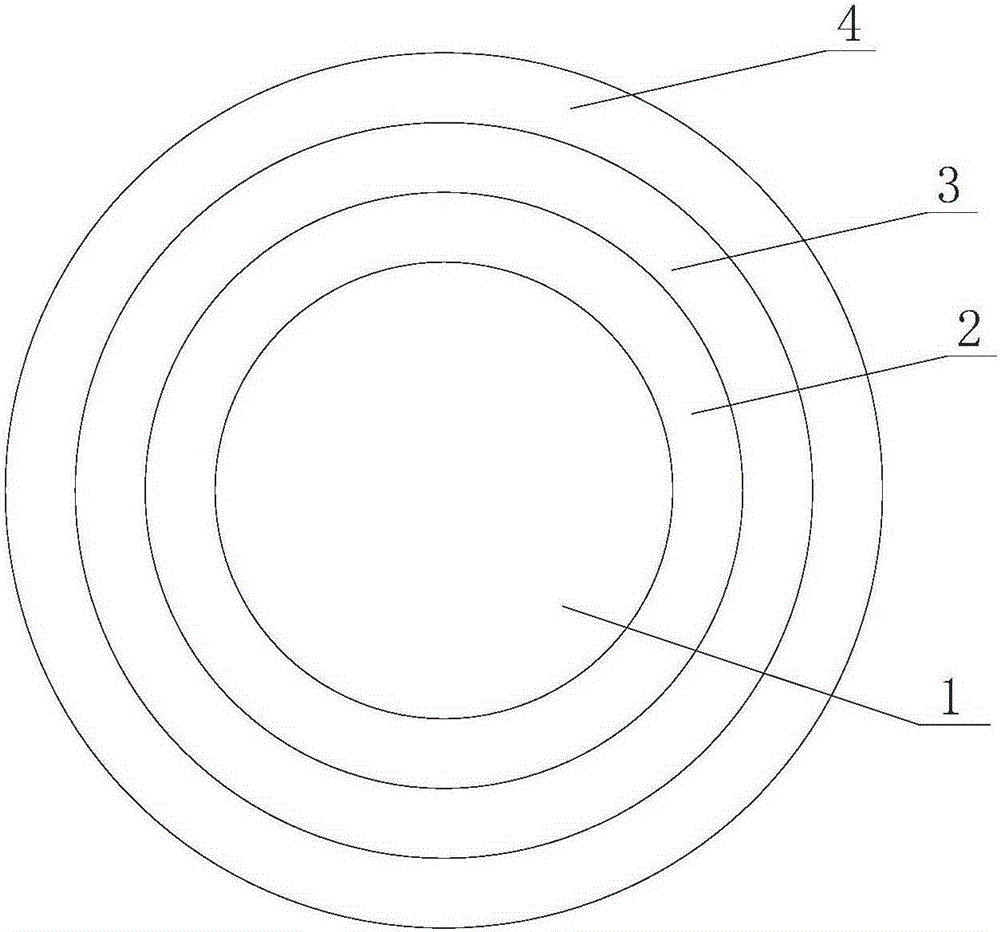

[0017] refer to figure 1 , a heat-conducting and flame-retardant control cable, comprising a wire core 1, an insulating layer 2, a shielding layer 3, and a sheath layer 4, the insulating layer 2 wrapping the outside of the wire core 1, the shielding layer 3 wrapping outside the insulating layer 2, and the sheath Layer 4 is wrapped outside the shielding layer 3; the insulating layer 2 is made of low-smoke halogen-free polyolefin material.

[0018] The raw materials of low-smoke halogen-free polyolefin materials include: 60 parts of polypropylene, 15 parts of methyl vinyl silicone rubber, 20 parts of ethylene-vinyl acetate copolymer, 1 part of tetrapropylbenzenesulfonyl, isopropyl 3 parts of tris(isostearyl) titanate, 2 parts of caprolactam, 1 part of magnesium oxide, 1 part of 2,5-dimethyl-2,5-di-tert-butylperoxy-3-hexyne, alkane 1.5 parts of alkylated diphenylamine, 1.5 parts of 2-mercaptobenzimidazole zinc salt, 2 parts of dicyclohexyl phthalate, 20 parts of kaolin, 15 parts...

Embodiment 2

[0020] refer to figure 1 , a heat-conducting and flame-retardant control cable, comprising a wire core 1, an insulating layer 2, a shielding layer 3, and a sheath layer 4, the insulating layer 2 wrapping the outside of the wire core 1, the shielding layer 3 wrapping outside the insulating layer 2, and the sheath Layer 4 is wrapped outside the shielding layer 3; the insulating layer 2 is made of low-smoke halogen-free polyolefin material.

[0021] The raw materials of low-smoke halogen-free polyolefin materials include: 60 parts of polypropylene, 15 parts of methyl vinyl silicone rubber, 20 parts of ethylene-vinyl acetate copolymer, 1 part of tetrapropylbenzenesulfonyl, isopropyl 3 parts of tri(isostearyl) titanate, 2 parts of caprolactam, 1 part of magnesium oxide, 1-2 parts of 2,5-dimethyl-2,5-di-tert-butylperoxy-3-hexyne , 0.5 parts of alkylated diphenylamine, 3 parts of 2-mercaptobenzimidazole zinc salt, 1.2 parts of dicyclohexyl phthalate, 35 parts of kaolin, 5 parts of c...

Embodiment 3

[0023] refer to figure 1 , a heat-conducting and flame-retardant control cable, comprising a wire core 1, an insulating layer 2, a shielding layer 3, and a sheath layer 4, the insulating layer 2 wrapping the outside of the wire core 1, the shielding layer 3 wrapping outside the insulating layer 2, and the sheath Layer 4 is wrapped outside the shielding layer 3; the insulating layer 2 is made of low-smoke halogen-free polyolefin material.

[0024] The raw materials of low-smoke halogen-free polyolefin materials include by weight: 48 parts of polypropylene, 20 parts of methyl vinyl silicone rubber, 18 parts of ethylene-vinyl acetate copolymer, 1.2 parts of tetrapropylbenzenesulfonyl, isopropyl 2 parts of tris(isostearyl) titanate, 3 parts of caprolactam, 0.8 parts of magnesium oxide, 1.2 parts of 2,5-dimethyl-2,5-di-tert-butylperoxy-3-hexyne, 1.3 parts of alkylated diphenylamine, 1.8 parts of 2-mercaptobenzimidazole zinc salt, 1.6 parts of dicyclohexyl phthalate, 30 parts of ka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com