Environment-friendly antibacterial ABS plastic and preparation method thereof

An ABS plastic, environmentally friendly technology, applied in the field of plastics, can solve the problems of affecting the performance stability and service life of plastics, difficult to disperse uniformly, and high toxicity to the human body, and achieve the effect of significant antibacterial effect, low cost, and fast sterilization speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

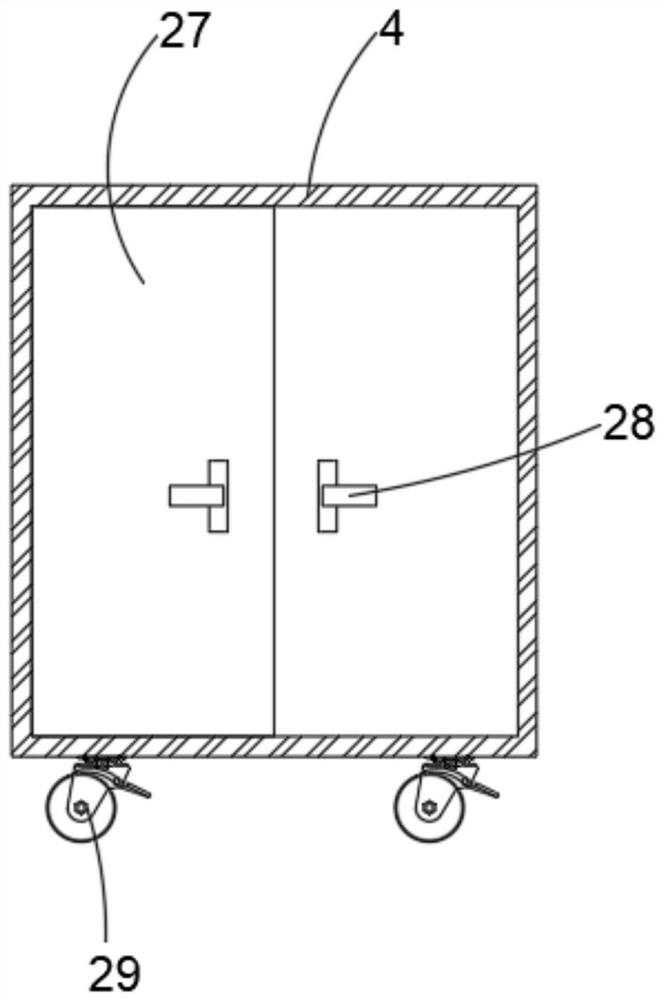

[0047] see figure 1 As shown, an environment-friendly antibacterial ABS plastic comprises an ABS plastic layer 1, the upper surface of the ABS plastic layer 1 is covered with a second protective layer 2, and the upper surface of the second protective layer 2 is covered with a first protective layer 3;

[0048] The ABS plastic layer is composed of the following components by weight: 75 parts of recycled ABS particles, 30 parts of silicone rubber, 25 parts of polylactic acid, 15 parts of modified montmorillonite, 6 parts of compound antibacterial agent, 3 parts of heat-resistant agent, 3 parts of dispersant, 2 parts of silane coupling agent, 2 parts of antioxidant, 1 part of plasticizer;

[0049] The preparation method of the modified montmorillonite comprises the following steps:

[0050] Disperse 1 part of silane coupling agent in a mixed solution of ethanol and deionized water, then add 90 parts of montmorillonite, stir at room temperature for 2 hours, add 30 parts of ferri...

Embodiment 2

[0070] see figure 1 As shown, an environment-friendly antibacterial ABS plastic comprises the ABS plastic layer 1, the upper surface of the ABS plastic layer 1 is covered with a second protective layer 2, and the upper surface of the second protective layer 2 is covered with a first protective layer 2. protective layer 3;

[0071] The ABS plastic layer is composed of the following components by weight: 77 parts of recycled ABS particles, 40 parts of silicone rubber, 30 parts of polylactic acid, 20 parts of modified montmorillonite, 8 parts of composite antibacterial agent, 6 parts of heat-resistant agent, 4 parts of dispersant, 3 parts of silane coupling agent, 2.5 parts of antioxidant, 2 parts of plasticizer;

[0072] The preparation method of the modified montmorillonite comprises the following steps:

[0073] Disperse 1.5 parts of silane coupling agent in a mixed solution of ethanol and deionized water, then add 93 parts of montmorillonite, stir at room temperature for 2 ...

Embodiment 3

[0093] see figure 1 As shown, an environment-friendly antibacterial ABS plastic comprises an ABS plastic layer 1, the upper surface of the ABS plastic layer 1 is covered with a second protective layer 2, and the upper surface of the second protective layer 2 is covered with a first protective layer 3;

[0094] The ABS plastic layer is composed of the following components in parts by weight: 80 parts of recycled ABS particles, 45 parts of silicone rubber, 40 parts of polylactic acid, 25 parts of modified montmorillonite, 10 parts of compound antibacterial agent, 8 parts of heat-resistant agent, 6 parts of dispersant, 4 parts of silane coupling agent, 3 parts of antioxidant, 3 parts of plasticizer;

[0095] The preparation method of the modified montmorillonite comprises the following steps:

[0096] Disperse 2 parts of silane coupling agent in a mixed solution of ethanol and deionized water, then add 95 parts of montmorillonite, stir at room temperature for 2 hours, add 90 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com