Additive composition for polyolefin

A composition and polyolefin technology, applied in the field of polyolefin processing, can solve the problems of poor surface affinity of polyolefin, reduced tensile strength of film system, poor dispersion of semi-matte masterbatch, etc., to reduce crystallization defects, reduce The effect of agglomeration between particles and excellent tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: granulation of fluoroelastomer, comprising the following steps:

[0031] The block rubber material of the vinylidene-tetrafluoroethylene-hexafluoropropylene copolymer is cut into rubber strips with a width of about 5cm by automatic cutting machine, and crushed into particles with a particle size of 1-3mm in the crusher, frozen milling powder, through a 20 mesh sieve, to obtain the particles of fluoroelastomer.

Embodiment 2

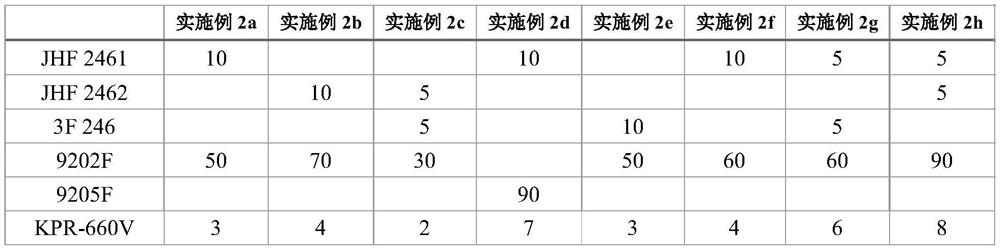

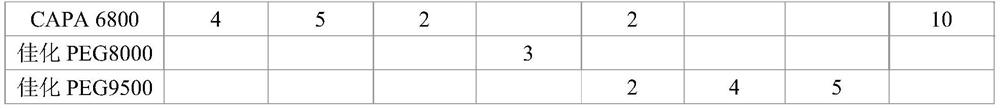

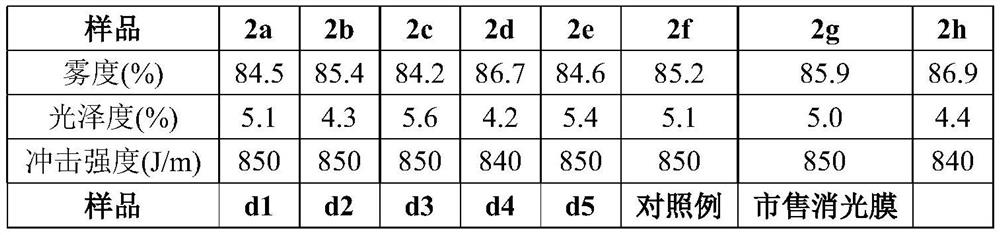

[0032] Example 2: an additive composition for polyolefins, comprising the following components by weight as shown in the following table: wherein the fluoroelastomer is a granuled particle obtained by Example 1;

[0033] Table 1: Example material formula ratio table (by weight)

[0034]

[0035]

Embodiment 2a

[0036] Example 2a: take 5kg of JHF 2461, 25kg of 9202F, 1.5kg of KPR-660V and 2 parts CAPA 6800, placed in a 100 kg horizontal vacuum mixer, using circulating cooling water to maintain the stirring temperature below 30 ° C, stirred evenly at a speed of 100 rpm, to give polyolefin additive composition 2a;

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com