Polymer resin adhesive for profile control and water plugging of oil and water wells

A polymer resin, profile control and water blocking technology, applied in the types of packaging items, transportation and packaging, liquid materials, etc., can solve the problems of oil field water production, insufficient thickening, and the effect of injection profile uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] like Figure 1-8 shown,

[0068] A polymer resin glue for profile control and water plugging of oil and water wells. The polymer resin glue for profile control and water plugging of oil and water wells is composed of the following components: 3% of polymer resin, 4% of water-soluble monomer, and 0.1% of crosslinking agent , initiator 0.01%, oxygen scavenger 0.2%, antacid stabilizer 0.1%, and the balance is water.

[0069] The polymer resin is carboxymethyl starch.

[0070] The water-soluble monomer is 2-acrylamide-2-methylpropanesulfonic acid.

[0071] The crosslinking agent is N-methylformamide.

[0072] The initiator is potassium peroxypyrophosphate.

[0073] The oxygen scavenger is sodium bisulfite.

[0074] The antacid stabilizer is scleroglucan.

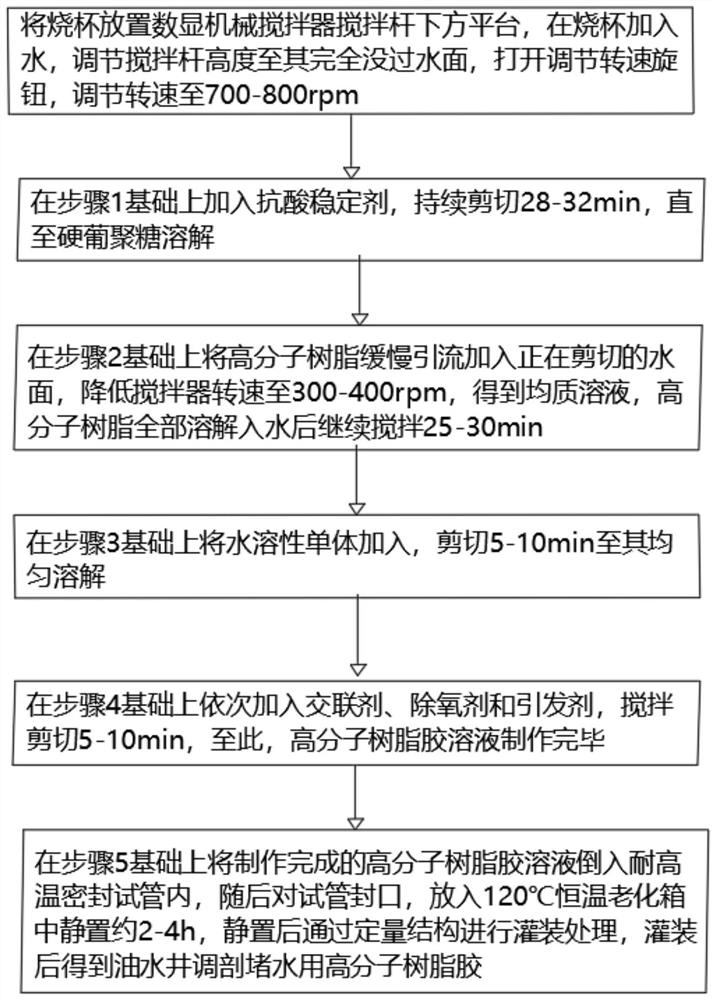

[0075] A preparation process of a polymer resin glue for profile control and water plugging of oil and water wells, the preparation process steps are as follows:

[0076] Step 1, place the beaker on the platform be...

Embodiment 2

[0083] Embodiment 2 is a further improvement of Embodiment 1.

[0084] like Figure 1-8 shown,

[0085] A polymer resin glue for profile control and water plugging of oil and water wells. The polymer resin glue for profile control and water plugging of oil and water wells is composed of the following components: 4% of polymer resin, 3% of water-soluble monomer, and 0.2% of cross-linking agent , initiator 0.05%, oxygen scavenger 0.2%, antacid stabilizer 0.2%, and the balance is water.

[0086] The polymer resin is carboxymethyl starch.

[0087] The water-soluble monomer is 2-acrylamide-2-methylpropanesulfonic acid.

[0088] The crosslinking agent is N-methylformamide.

[0089] The initiator is potassium peroxypyrophosphate.

[0090] The oxygen scavenger is sodium bisulfite.

[0091] The antacid stabilizer is scleroglucan.

[0092] A preparation process of a polymer resin glue for profile control and water plugging of oil and water wells, the preparation process steps are...

Embodiment 3

[0111] Example 3 is a further improvement of Example 1.

[0112] like Figures 13 to 22 As shown in the figure, a device for oil and water well profile control and water plugging with polymer resin glue, the device is the quantitative structure in step 3, and includes a first support frame 1, and the first support frame 1 is rotatably connected by a fixedly connected bearing There is a conveyor belt 3, a first drive motor 2 is fixedly installed on the rear side wall of the first support frame 1, and the first drive motor 2 is fixedly connected with one end of the rotating shaft of the conveyor belt 3;

[0113] The top of the first support frame 1 is used for the centering structure 4 for guiding the oil drum. The centering structure 4 includes a latch 401, a positioning hole 402, a sliding cross plate 403, a tension spring 404, a convex block 405, a straight limit plate 406, and an oblique guide. The plate 407 and the sliding hole 408, the top of the convex block 405 is fixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com