Rapid pre-cooling concrete dam refrigeration equipment

A technology for concrete dams and refrigeration equipment, which is used in household refrigeration devices, lighting and heating equipment, cooling fluid circulation devices, etc., can solve the problem that dust cannot be cleaned out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

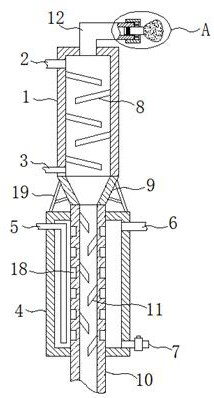

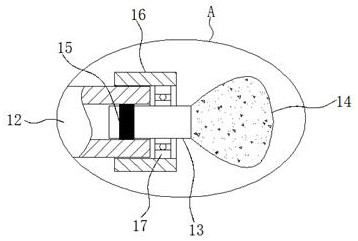

Embodiment 1

[0023] Example 1 as Figure 1-2 As shown, this rapid precooling concrete dam refrigeration equipment includes a rectangular pipe 1, an aggregate feed pipe 2, a cold air inlet pipe 3, a barrel body 4, a liquid ammonia inlet pipe 5, an ammonia gas outlet pipe 6 and a liquid ammonia outlet pipe 6. The ammonia outlet pipe 7 is fixedly connected to the inner wall of the rectangular pipe 1 with a plurality of evenly staggered first slow flow plates 8, the rectangular pipe 1 is provided with an opening at the bottom, and the opening position is fixedly connected with a tapered bucket 9, the tapered The bottom end of the bucket 9 is fixedly connected with a feed pipe 10, and the feed pipe 10 is arranged through the barrel body 4, and the inner wall of the feed pipe 10 located in the barrel body 4 is fixedly connected with a plurality of evenly staggered second buffers. The flow plate 11, the aggregate feeding pipe 2 is fixedly connected with the position near the top of the rectangula...

Embodiment 2

[0025] Embodiment 2 is on the basis of embodiment 1 such as figure 1 As shown, its feed pipe 10 is made of copper material, and a plurality of evenly distributed grooves 18 are provided on the outer wall of the feed pipe 10 located in the barrel body 4 to increase the contact area and improve the pre-cooling efficiency.

Embodiment 3

[0026] Embodiment 3 is such as on the basis of embodiment 1 figure 1 As shown, the air outlet of its cold air inlet pipe 3 is located below the first slow flow plate 8 to prevent the aggregate from entering the cold air inlet pipe 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com