Foaming cement board cutting device

A foamed cement board and cutting device technology, applied in cleaning devices, transportation and packaging, manufacturing tools, etc., can solve the problems of scrapping, low yield rate, etc., and achieve the effect of accurate cutting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

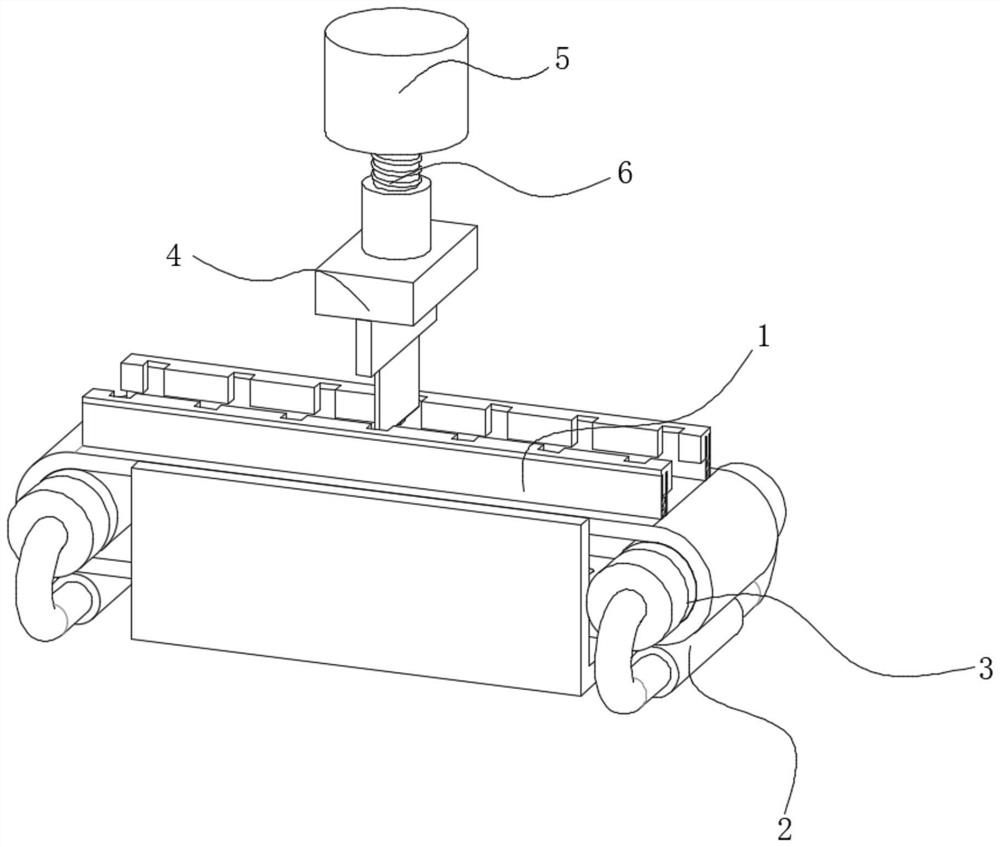

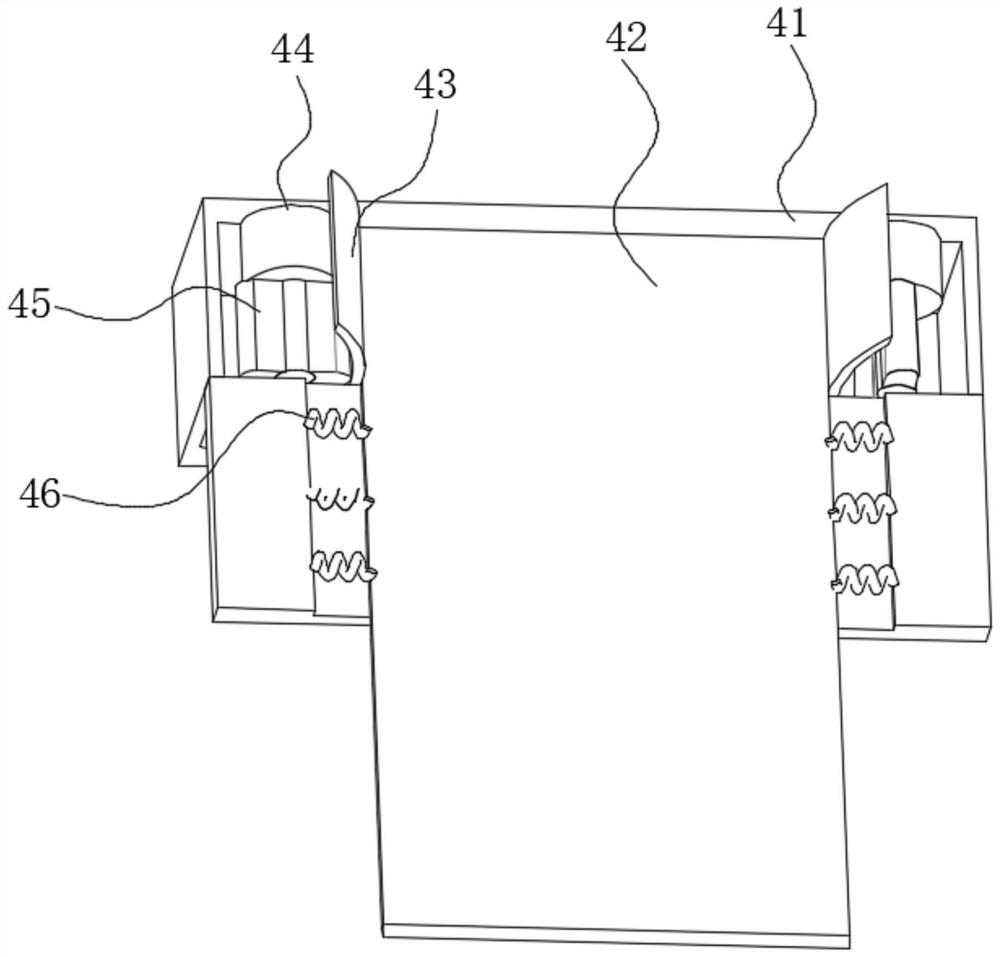

[0032] see Figure 1-Figure 4 , the present invention provides a technical solution: a foamed cement board cutting device, comprising a transport device 1, a torque motor 3 is symmetrically arranged on the left and right sides of the inner wall of the transport device 1, and one side of the outer surface of the motor shell of the torque motor 3 is fixed An adjustment connecting rod 2 is connected, a cutting device 4 is clamped on the upper surface of the transport device 1, a threaded sleeve 6 is fixedly connected to the upper surface of the cutting device 4, and an adjustment rotating column 5 is rotatably connected to the upper part of the inner wall of the threaded sleeve 6.

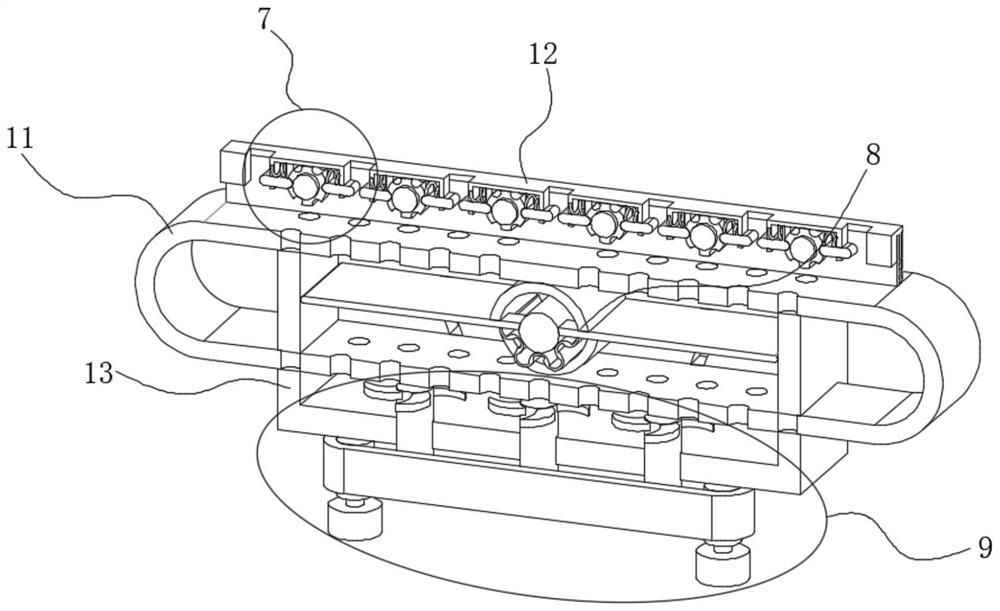

[0033] The transport device 1 includes a transmission belt 11. The front and rear sides of the upper surface of the transmission belt 11 are symmetrically provided with guiding side rails 12. The inner wall of the guiding side rails 12 is evenly provided with an anti-skid device 7. The lower part of th...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides a technical solution: on the basis of the first embodiment, a foamed cement board cutting device includes a transportation device 1, and the left and right sides of the inner wall of the transportation device 1 are symmetrically arranged with a torque motor 3, and the torque motor 3 is electrically One side of the outer surface of the casing is fixedly connected with an adjustment connecting rod 2, the upper surface of the transport device 1 is clamped with a cutting device 4, and the upper surface of the cutting device 4 is fixedly connected with a threaded sleeve 6, and the upper part of the inner wall of the threaded sleeve 6 rotates An adjustment rotary column 5 is connected.

[0041] The transport device 1 includes a transmission belt 11. The front and rear sides of the upper surface of the transmission belt 11 are symmetrically provided with guiding side rails 12. The inner wall of the guiding side rails 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com