Copper gallium sulfide/zinc selenide core-shell structure quantum dot and preparation method and application thereof

A core-shell structure, zinc selenide technology, applied in chemical instruments and methods, photosensitive equipment, energy input and other directions, can solve the problems of low stability, high toxicity of quantum dots, and many surface defect states, and achieves good stability, The effect of suppressing non-radiative recombination and increasing photocurrent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A copper gallium sulfur / zinc selenide core-shell quantum dot, the preparation method comprising the following steps:

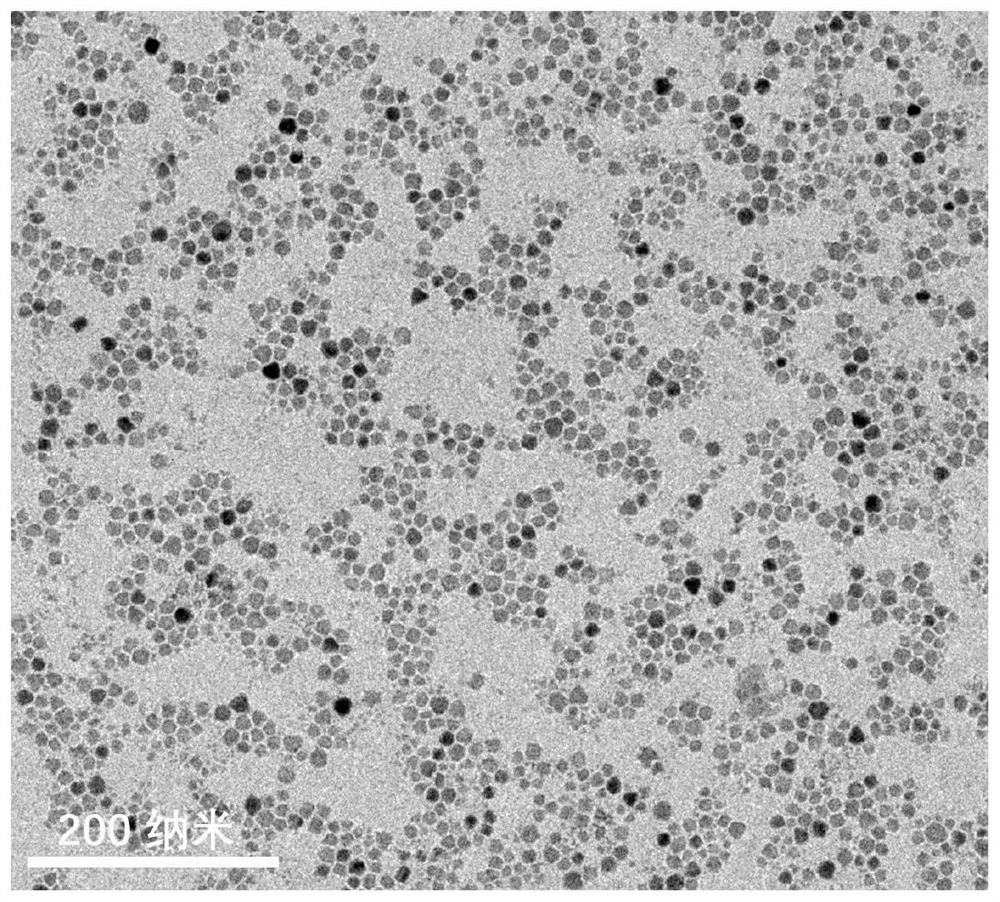

[0028] (1) Synthesis of CuGaS 2 (CGS) Nuclear quantum dots: 0.25 mmol cuprous iodide, 0.25 mmol gallium iodide and 2.5 ml oleylamine were placed in a 50 ml three-necked flask with a magnetic stirrer, then the reaction mixture was heated to 70 °C under nitrogen Purge until the color changes to dark green, then inject 0.25 ml of 1-dodecyl mercaptan, the solution then turns to a clear pale yellow, then quickly becomes opaque milky white, and then the temperature is raised to 120 °C, and the solution is heated under nitrogen. It was degassed in the environment for 60min, then heated to 180°C, then injected with 0.25ml of sulfur precursor solution, and kept for 5min to form nuclear layer quantum dots, then heated to 220°C and kept for 20min, after which the reaction was stopped by water bath quenching, and finally the The reaction liquid is transferred to a...

Embodiment 2

[0032] A copper gallium sulfur / zinc selenide core-shell quantum dot, the preparation method comprising the following steps:

[0033] (1) Synthesis of CuGaS 2 (CGS) nuclear quantum dots: 0.25 mmol cuprous iodide, 0.25 mmol gallium iodide and 2.5 ml oleylamine were placed in a 50 ml three-necked flask with a magnetic stirrer, then the reaction mixture was heated to 65 °C under nitrogen Purge until the color changes to dark green, then inject 0.25 ml of 1-dodecyl mercaptan, the solution then becomes clear pale yellow, then quickly becomes opaque milky white, then warm to 110 °C, keep the solution under nitrogen It was degassed in the environment for 65min, then heated to 170°C, then injected with 0.25ml of sulfur precursor solution, and kept for 6min to form nuclear layer quantum dots, then heated to 210°C and kept for 22min, after which the reaction was stopped by water bath quenching, and finally the The reaction liquid is transferred to a centrifuge tube for centrifugal colle...

Embodiment 3

[0037] A copper gallium sulfur / zinc selenide core-shell quantum dot, the preparation method comprising the following steps:

[0038] (1) Synthesis of CuGaS 2 (CGS) nuclear quantum dots: 0.25 mmol cuprous iodide, 0.25 mmol gallium iodide and 2.5 ml oleylamine were placed in a 50 ml three-necked flask with a magnetic stirrer, then the reaction mixture was heated to 75 °C under nitrogen Purge until the color changes to dark green, then inject 0.25 ml of 1-dodecyl mercaptan, the solution then turns to a clear pale yellow, then quickly becomes opaque milky white, then warm to 130 °C, keep the solution under nitrogen It was degassed in the environment for 55min, then heated to 190°C, then injected with 0.25ml of sulfur precursor solution, and kept for 4min to form nuclear layer quantum dots, then heated to 230°C and kept for 18min, after which the reaction was stopped by water bath quenching, and finally the The reaction liquid is transferred to a centrifuge tube for centrifugal co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com