Amphiphilic polymer taking polyhedral oligomeric silsesquioxane as core and modified LMHs

A silsesquioxane, amphiphilic technology, applied in the field of inorganic/organic hybrid materials, can solve the problems of poor dispersion, affecting the mechanical properties of materials, etc., to improve compatibility, reduce force, and increase interlayer spacing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1 PEG-T 10 Preparation of -COOH

[0062] (1) Add 7g CH 3 OK (100mmol) was packed into a 250ml single-necked flask, 90ml of isopropanol was added, 1.8ml of H 2 O (100mmol), the reaction system is white and turbid; 19g (100mmol) vinyltriethoxysilane and 20ml isopropanol that have been added to the constant pressure funnel are slowly added dropwise to the flask, about 10min, and react at room temperature for 24h; continue Add conc. 4 ;

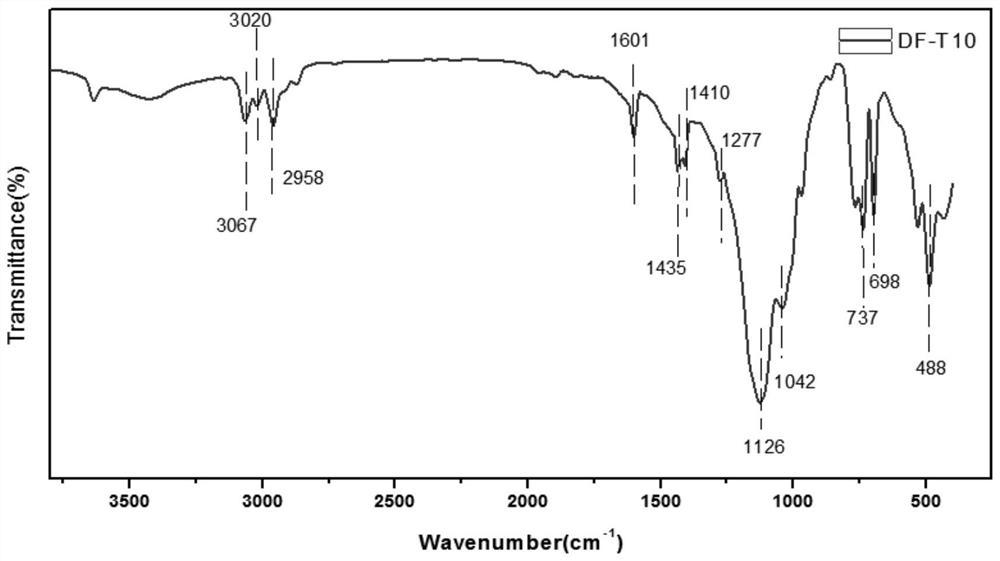

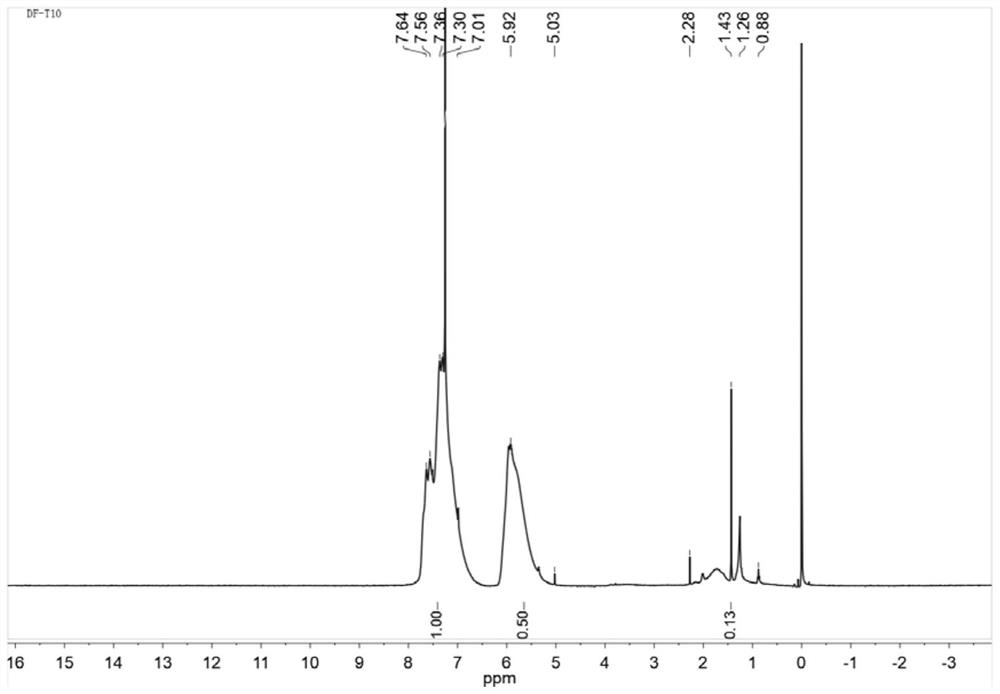

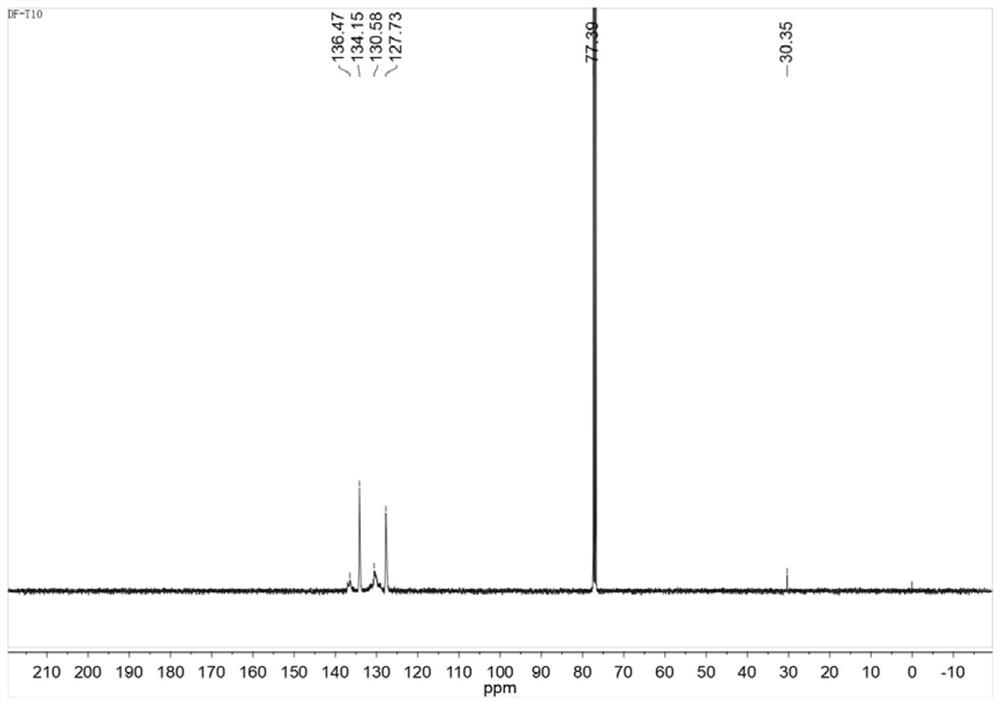

[0063] (2) The T obtained in step (1) 4 Take 3.5g (10mmol) and 100ml 1,4-dioxane in a 500ml three-necked flask, add 2.3g potassium methoxide and 2g water, stir to dissolve, and pass through N 2 , then slowly add 12.3g (62mmol) of phenyltrimethoxysilane (PTMS) that has been added in the constant pressure funnel into the flask, and at the same time add the catalyst tetramethylammonium fluoride 0.14g (0.146mmol), after the dropwise addition is completed React at 40°C for 24 hours, and then add anhydrous calcium chloride as a cat...

Embodiment 2

[0066] Example 2 PEG-T 10 Preparation of -COOH

[0067] (1) Add 7g CH 3 OK (100mmol) was packed into a 250ml single-necked flask, 90ml of isopropanol was added, 1.8ml of H 2 O (100mmol), the reaction system is white and turbid; 19g (100mmol) vinyltriethoxysilane and 20ml isopropanol that have been added to the constant pressure funnel are slowly added dropwise to the flask, about 10min, and react at room temperature for 24h; continue Add conc. 4 ;

[0068] (2) The T obtained in step (1) 4 Take 3.5g (10mmol) and 100ml 1,4-dioxane in a 500ml three-necked flask, add 2.3g potassium methoxide and 2g water, stir to dissolve, and pass through N 2 , then slowly add 14.9g (62mmol) of phenyltriethoxysilane (PTES) that has been added in the constant pressure funnel into the flask, and add catalyst trihydrate tetrabutylammonium fluoride 0.063g (0.2mmol) at the same time, drop After the addition was completed, react at 40°C for 24 hours, and then add anhydrous calcium chloride as a c...

Embodiment 3

[0071] Example 3 PEG-T 10 Preparation of -COOH

[0072] (1) Add 7g CH 3 OK (100mmol) was packed into a 250ml single-necked flask, 90ml of isopropanol was added, 1.8ml of H 2 O (100mmol), the reaction system is white and turbid; 19g (100mmol) vinyltriethoxysilane and 20ml isopropanol that have been added to the constant pressure funnel are slowly added dropwise to the flask, about 10min, and react at room temperature for 24h; continue Add conc. 4 ;

[0073] (2) The T obtained in step (1) 4 Take 3.5g (10mmol) and 100ml 1,4-dioxane in a 500ml three-necked flask, add 2.3g potassium methoxide and 2g water, stir to dissolve, and pass through N 2 , then slowly add 15.6g (65mmol) of phenyltriethoxysilane (PTES) that has been added in the constant pressure funnel into the flask, and add the catalyst benzyltrimethylammonium fluoride 0.25g (1.5mmol) at the same time, drop After the completion of the addition, react at 60°C for 24 hours, then add anhydrous calcium chloride as a cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com