Modeling and control method of hydraulic mechanical arm based on rotation and sliding separation

A technology of hydraulic machinery and control methods, which is applied in the directions of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high nonlinearity of the hydraulic control system, and achieve the effect of enhanced dynamic tracking effect, high control accuracy and fast dynamic response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

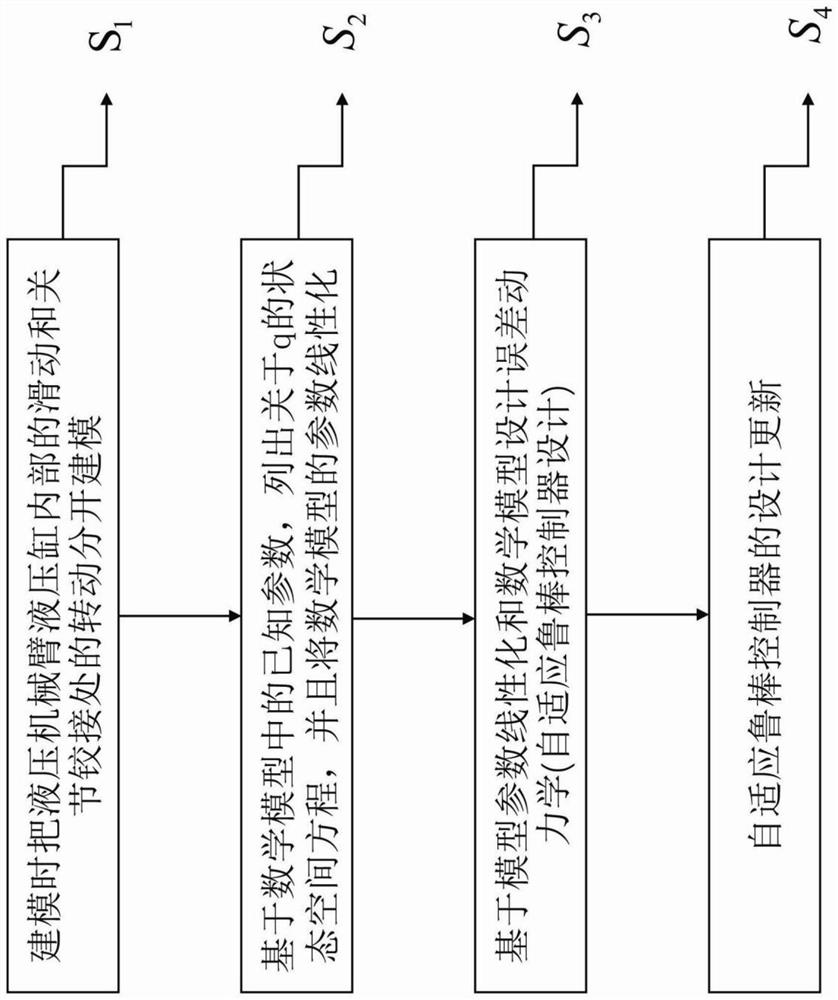

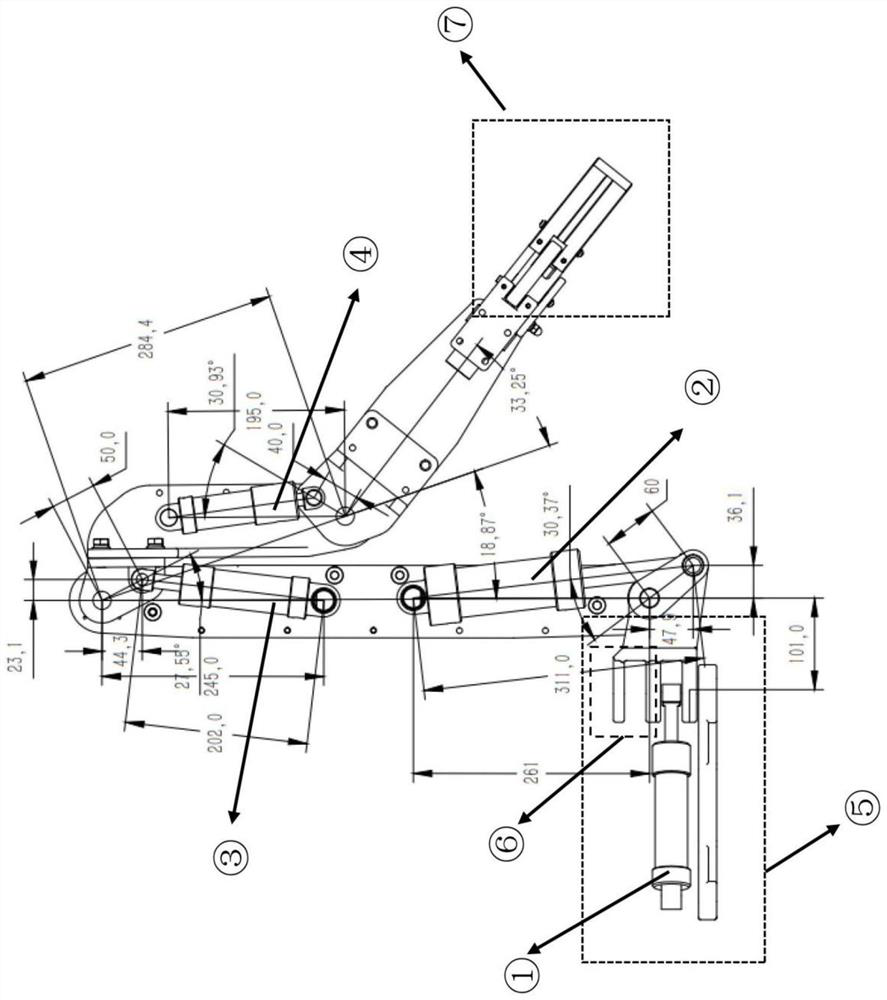

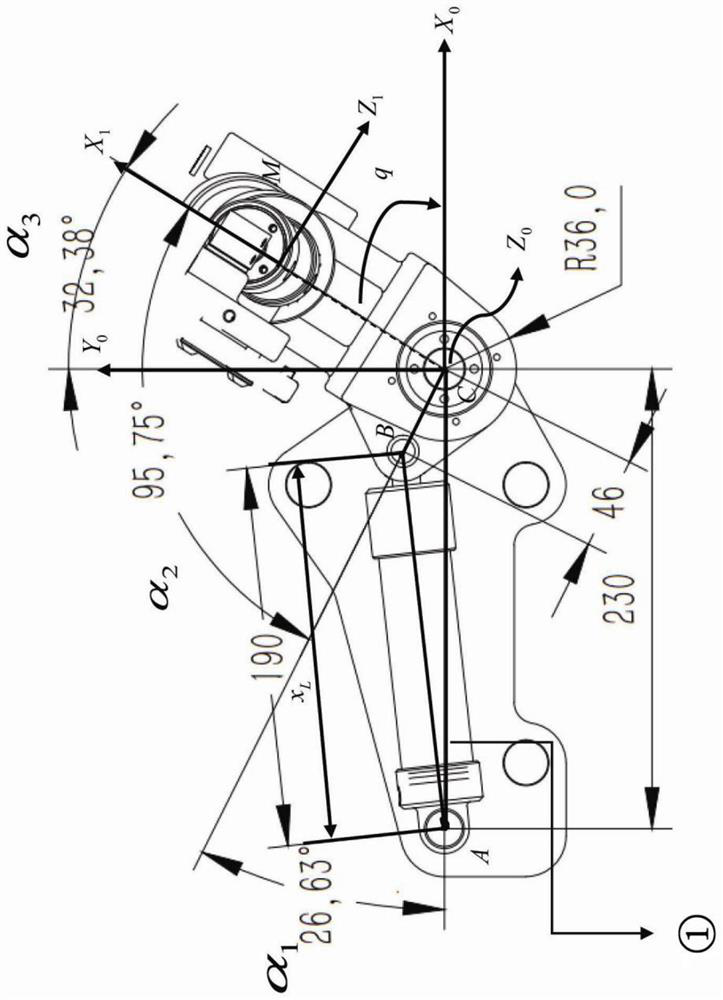

[0046] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the modeling and control method of the hydromechanical arm based on rotation and sliding separation of the present invention includes the following steps:

[0047] Step S1, when modeling, the sliding inside the hydraulic cylinder of the hydraulic manipulator and the rotation at the joint are separately modeled, and based on the separate modeling method, the sliding inside the hydraulic cylinder of the hydraulic manipulator and the rotation at the joint are established as hydraulic machinery The mathematical model of the arm, the mathematical model at this time is expressed as:

[0048]

[0049] Among them, J is the moment of inertia, the product of the mass and the square of the radius of gyration and is a constant value, which is measured (can be determined by parameter identification), is the partial derivative; represents the sliding friction inside the hydraulic cylinder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com