A real-time simulation method for in-plane tire flexible ring model

A real-time simulation and realization method technology, applied in design optimization/simulation, instrumentation, geometric CAD, etc., can solve problems such as the inability to accurately express tire ground contact characteristics, increase the nonlinearity of the model, and reduce the calculation efficiency of the model. Real-time, saving time for solving, and calculating accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A method for realizing real-time simulation of an in-plane tire flexible ring model, comprising the following steps:

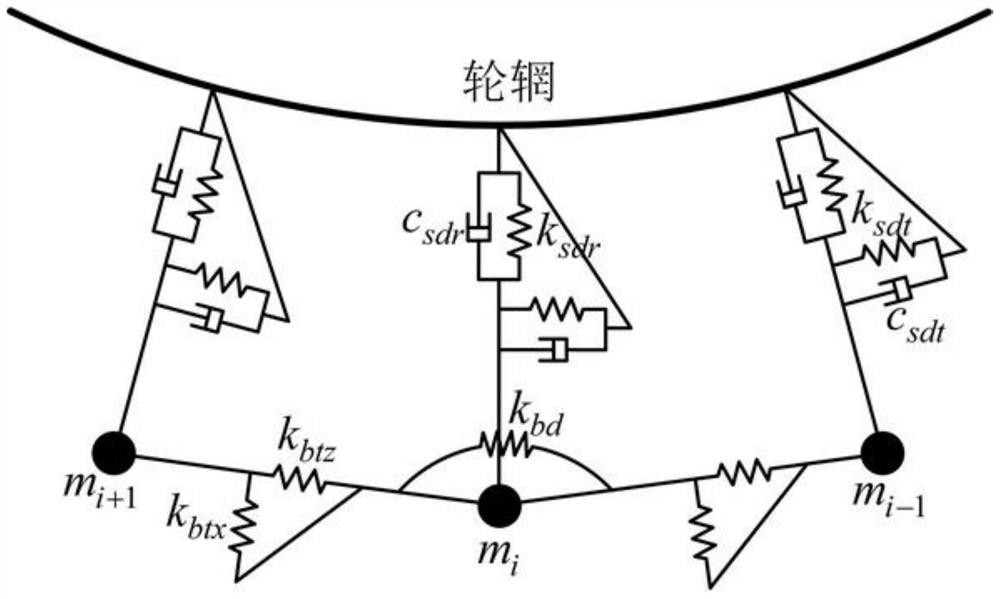

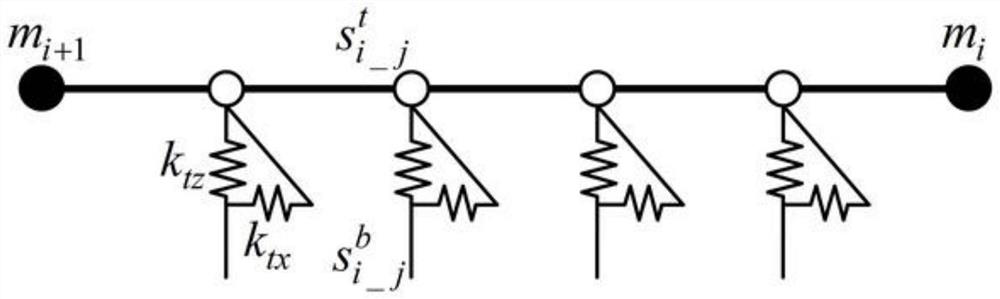

[0021] One, such as figure 1 As shown, the belt part is discretized into several uniformly distributed mass points m i , mass point m i They are connected by springs along the tire circumference and radial direction, expressing the tensile characteristics of the belt, and the adjacent three mass points m i The connection between them is performed by a bending spring to express the bending characteristics of the belt, and the mass point m i The tire sidewall and the compressed air inside the tire are understood by the spring damping unit along the tire circumference and radial direction with the rim. Such as figure 2 As shown, discretize the tread into a uniform distribution at the mass point m i Between the springs, the contact force between the tire and the road is calculated through the deformation of the spring.

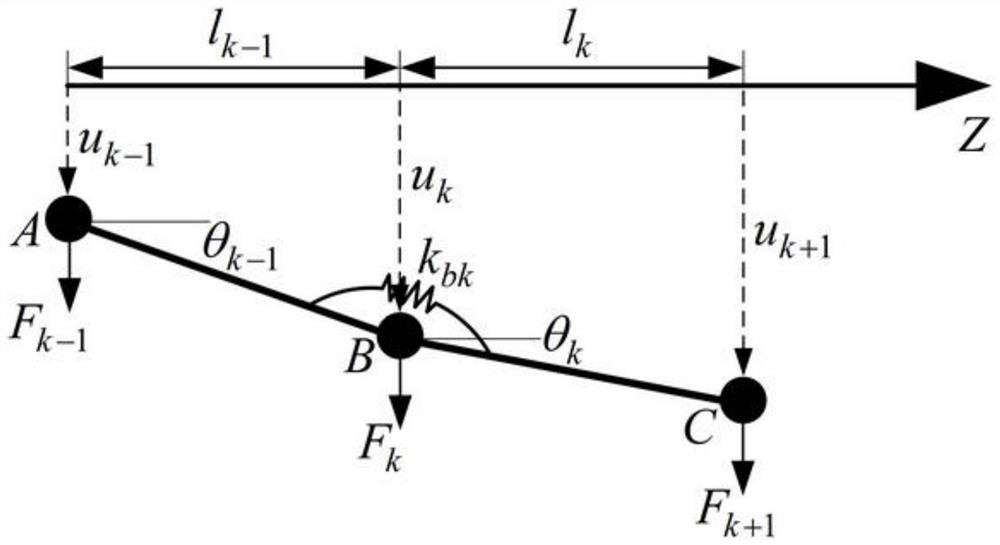

[0022] 2. For the mass point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com