Silicon carbide single crystal wafer, silicon carbide crystal, preparation method and semiconductor device

A silicon carbide single crystal, silicon carbide technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, chemical instruments and methods, etc., can solve the problems of reducing dislocation density and not improving device yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] In addition, an embodiment of the present invention also provides a method for preparing a silicon carbide crystal, please refer to Figure 12 , Figure 12 A flow chart of a method for preparing silicon carbide crystals provided in an embodiment of the present invention; the method for preparing silicon carbide crystals includes:

[0085] S101: pretreating the crucible containing the silicon carbide raw material with a graphite cover without a seed crystal;

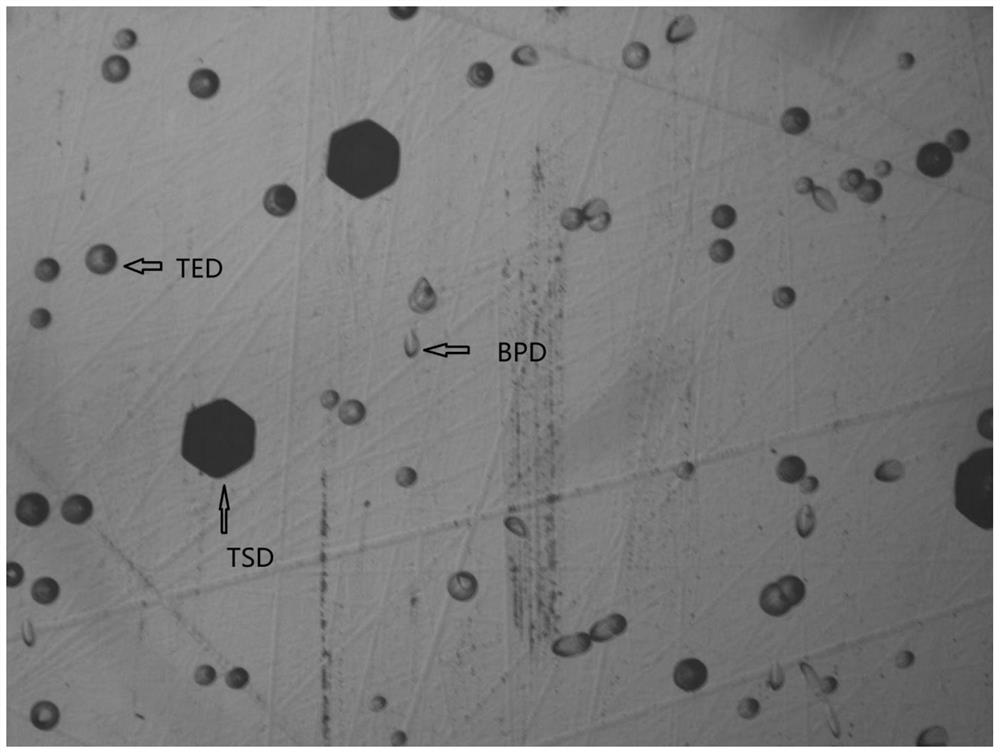

[0086] It should be noted that in the initial stage of silicon carbide growth, various defects such as carbon inclusions and polytypes will occur at the extension interface. Through a large number of mechanism research and analysis, the inventor found that it is easy to form aggregated screw dislocations at the defect positions of the inclusions, and polytype defects. It will lead to aggregated basal plane dislocations, aggregated edge dislocations, etc.

[0087] Through a lot of experimental research, the invent...

Embodiment 1

[0106]Example 1——The crucible containing the silicon carbide raw material is added with a graphite cover without seed crystal, and is loaded into the silicon carbide single crystal furnace, and the high temperature is 2200 degrees, and the pressure is lower than 0.1Pa, and the vacuum pump is turned on all the time. After 5 hours, the furnace was stopped and cooled, and the crucible containing the silicon carbide raw material was weighed. It was found that the weight decreased by 3%, indicating that the impurities on the raw material and the surface of the crucible, and the silicon-rich components have been effectively disposed of.

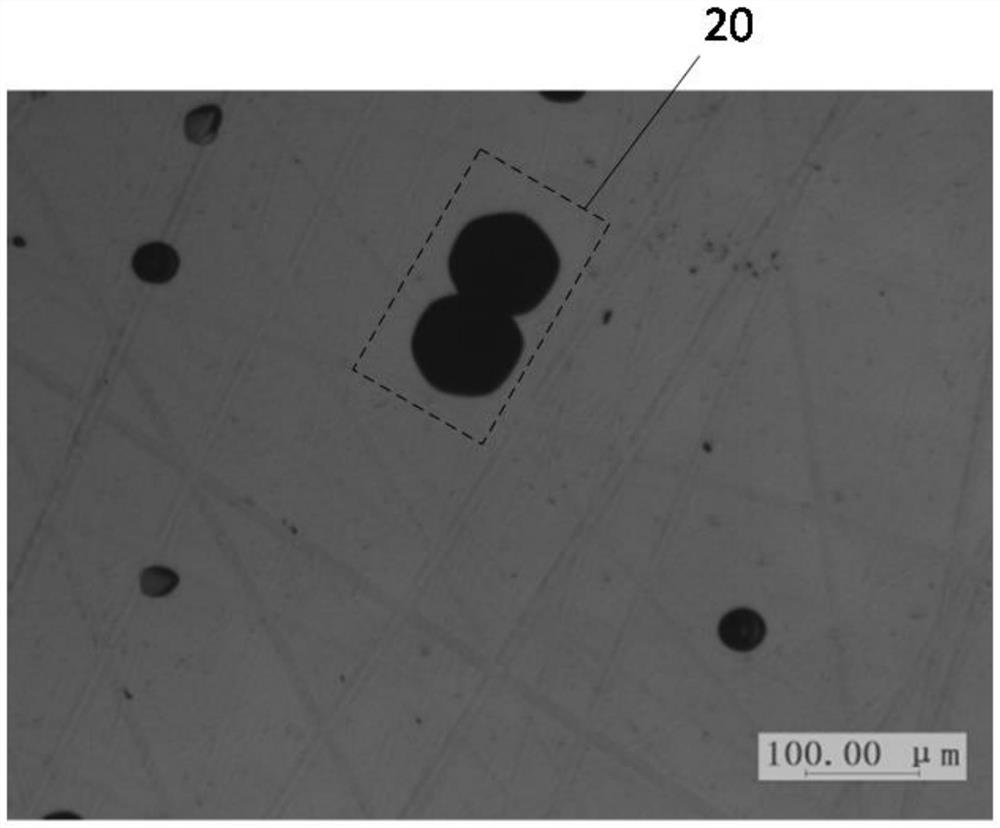

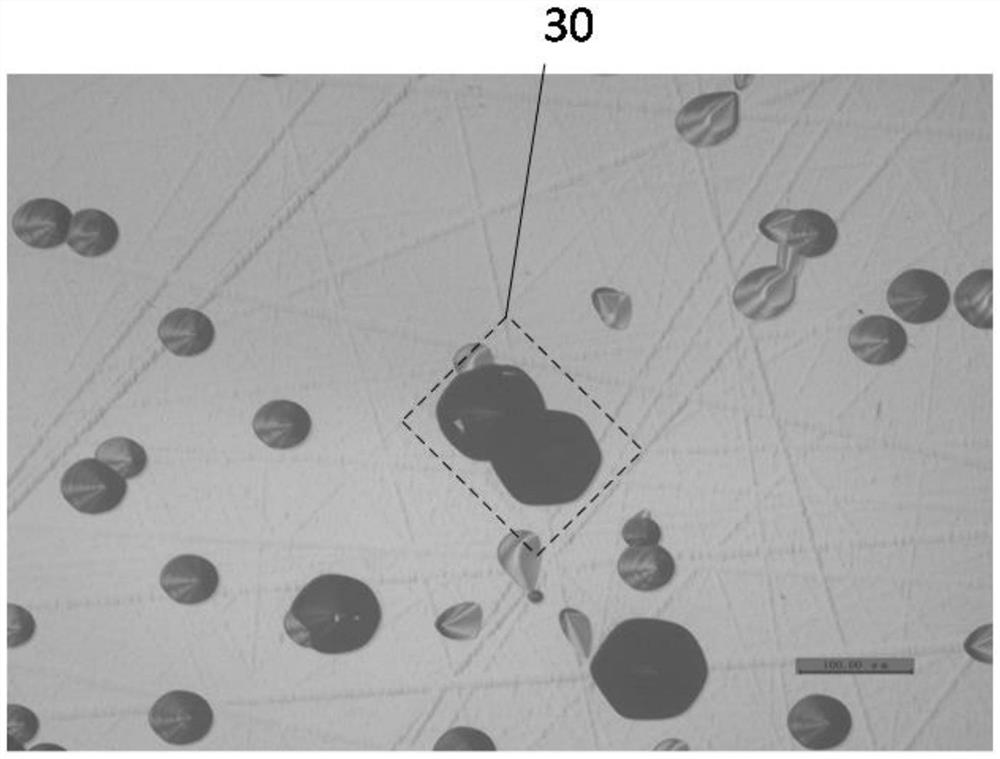

[0107] Select a 4-degree 6-inch seed crystal of a SiC sheet with low aggregate dislocation density, and fix the seed crystal to the lid. Replace a graphite cover without a seed crystal, install a cover with a seed crystal, and re-install the furnace for growth after assembly. The temperature is 2300 degrees, the fluctuation is less than 1 degree, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com