Natural plant extract modified compound corrosion inhibitor as well as preparation method and application thereof

A technology of natural plants and extracts, which is applied in the field of acetate production, can solve the problems of polluting the environment, not easy to degrade, etc., and achieve the effects of improving solubility, improving thermal stability, and good corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

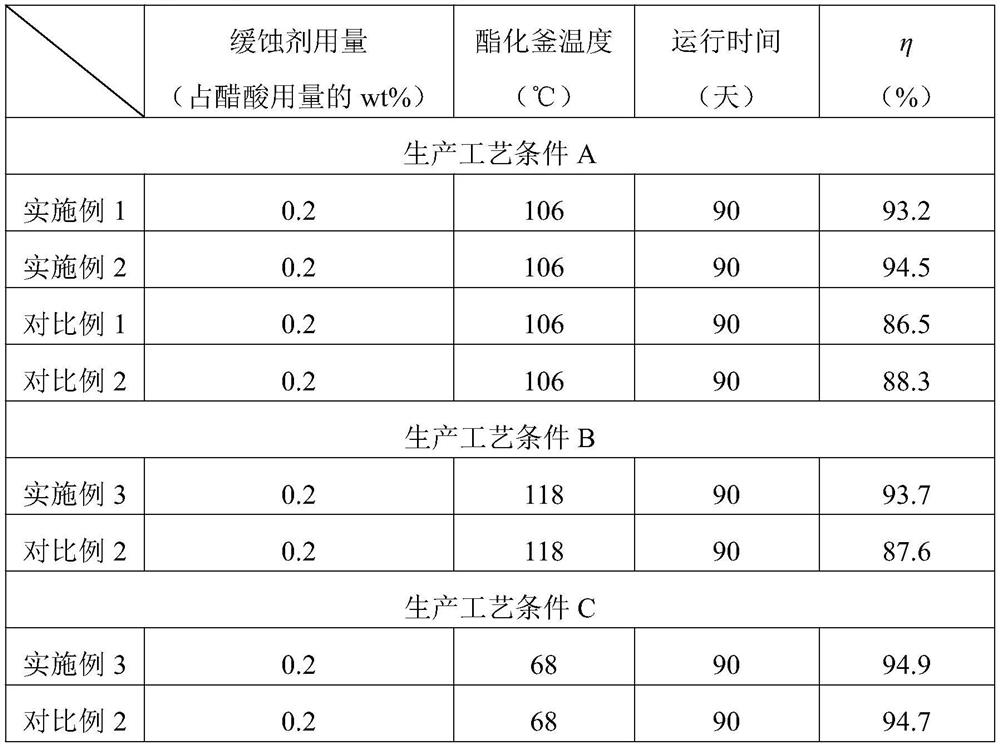

Embodiment 1

[0041] A natural plant extract modified compound corrosion inhibitor, which comprises the following components:

[0042] Glycidyl ester polymer 1 equivalent

[0043] 2-Phosphonic acid butane-1,2,4-tricarboxylic acid 1 equivalent

[0044] The preparation method of the above-mentioned natural plant extract modified compound corrosion inhibitor, comprises the following steps:

[0045] Preparation method of sugarcane leaf extract:

[0046] F1. Brush the collected fresh sugarcane leaves, remove impurities and moldy parts on the surface, and dry them naturally until the surface is free of moisture;

[0047] F2. In the round-bottomed flask, successively add 1 equivalent of washed and dried sugarcane leaves and 1 equivalent of dehydrated alcohol to obtain a mixture of sugarcane leaves and dehydrated ethanol, and leave it to stand for 10min;

[0048] F3. Add the mixture into the ultrasonic-microwave synergistic extraction apparatus, select an ultrasonic power of 300W, and an ultraso...

Embodiment 2

[0054] A natural plant extract modified compound corrosion inhibitor, which comprises the following components:

[0055] Glycidyl ester polymer 1 equivalent

[0056] 2-Phosphonobutane-1,2,4-tricarboxylic acid 2 equiv

[0057] The preparation method of the above-mentioned natural plant extract modified compound corrosion inhibitor, comprises the following steps:

[0058] Preparation method of sugarcane leaf extract:

[0059] F1. Brush the collected fresh sugarcane leaves, remove impurities and moldy parts on the surface, and dry them naturally until the surface is free of moisture;

[0060] F2. In the round-bottomed flask, successively add 1 equivalent of washed and dried sugarcane leaves and 2 equivalents of absolute ethanol to obtain a mixture of sugarcane leaves and absolute ethanol, and leave it to stand for 10min;

[0061] F3. Add the mixture into the ultrasonic-microwave synergistic extraction apparatus, select an ultrasonic power of 200W, and an ultrasonic time of 40m...

Embodiment 3

[0067] A natural plant extract modified compound corrosion inhibitor, which comprises the following components:

[0068] Glycidyl ester polymer 1 equivalent

[0069] 3-Phosphonobutane-1,2,4-tricarboxylic acid 3 equiv

[0070] The preparation method of the above-mentioned natural plant extract modified compound corrosion inhibitor, comprises the following steps:

[0071] Preparation method of sugarcane leaf extract:

[0072] F1. Brush the collected fresh sugarcane leaves, remove impurities and moldy parts on the surface, and dry them naturally until the surface is free of moisture;

[0073] F2. In the round-bottomed flask, successively add 1 equivalent of washed and dried sugarcane leaves and 1 equivalent of dehydrated alcohol to obtain a mixture of sugarcane leaves and dehydrated ethanol, and leave it to stand for 10min;

[0074] F3. Add the mixture into the ultrasonic-microwave synergistic extraction apparatus, select an ultrasonic power of 300W, and an ultrasonic time of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com