Single-component thermal interface material and preparation method thereof

A thermal interface material, one-component technology, applied in the field of thermal management, can solve the problems of difficult to meet the requirements of ultra-low thickness of the chip, inability to scale dispensing operations, reduced life and other problems, to achieve a stable and healthy working temperature environment, excellent Lipophilic and hydrophobic properties, the effect of improving life and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

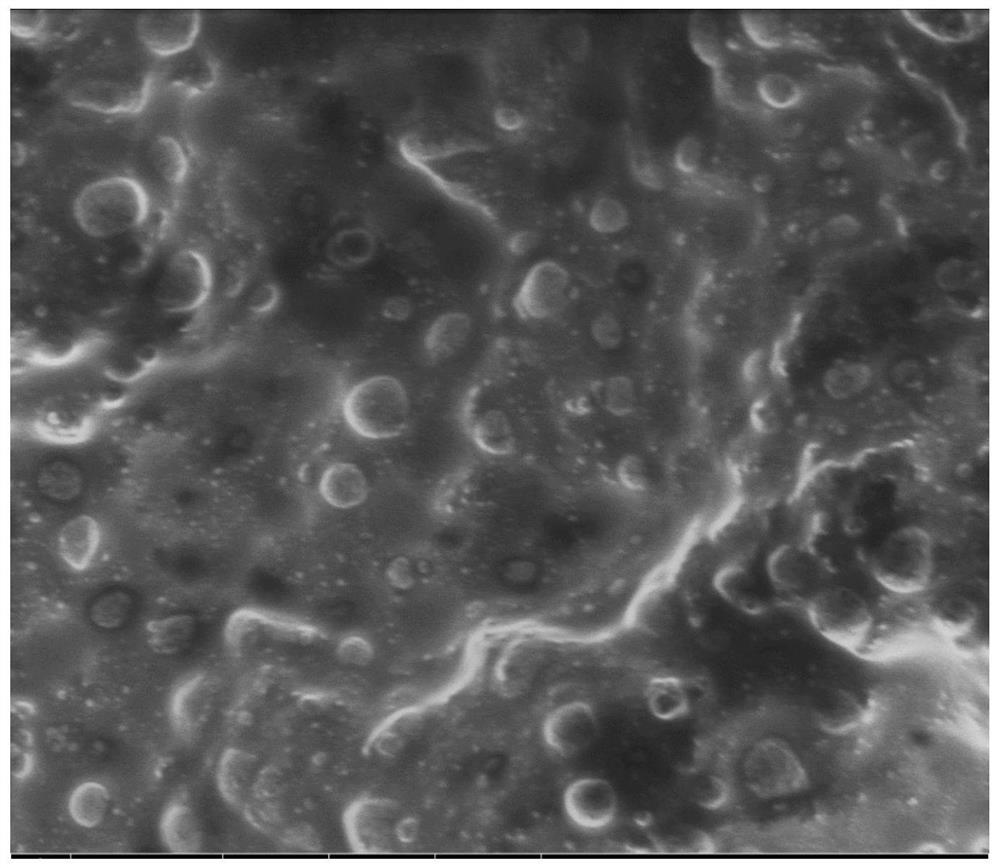

[0031] (1) Preparation of modified filler

[0032] Add 1kg of high-purity spherical aluminum powder to the planetary machine for stirring, and add the coupling agent mixture dropwise within 10 minutes. The coupling agent mixture is ready to use. The coupling agent mixture is 30g dodecyltrimethoxysilane, A combination of 10g absolute ethanol and 10g pure water.

[0033] The temperature was increased to 50°C in the planetary machine, and the temperature was stabilized for 2 hours; then the temperature was increased to 120°C, the vacuum was turned on after the temperature was stabilized, and the stirring was continued for 2 hours; finally, the modified filler was obtained by cooling to room temperature.

[0034] (2) Preparation of one-component thermal interface material

[0035] Turn on the planetary machine, add vinyl-terminated polysiloxane (the kinematic viscosity of vinyl-terminated polysiloxane is 20-1000cst, and the molar fraction of vinyl is 0.1-3.5%), hydrogen-terminate...

Embodiment 2

[0043] The difference between the preparation method provided in this example and Example 1 is:

[0044] In the preparation process of the modified filler, the coupling agent is cetyltrimethoxysilane.

Embodiment 3

[0046] The difference between the preparation method provided in this example and Example 1 is:

[0047] In the preparation process of the modified filler, the coupling agent mixture was a combination of 15 g of dodecyltrimethoxysilane, 5 g of absolute ethanol, and 5 g of pure water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com