Preparation method and application of nitrogen-doped carbon dot-reduced graphene oxide composite material

A technology of nitrogen-doped carbon dots and composite materials, applied in the field of composite materials, can solve the problems of electrochemical sensing sensitivity and detection limit difference, and the application of carbon quantum dots with poor conductivity, so as to improve the sensitivity and detection limit, and improve the conductivity rate and electron transport rate, the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

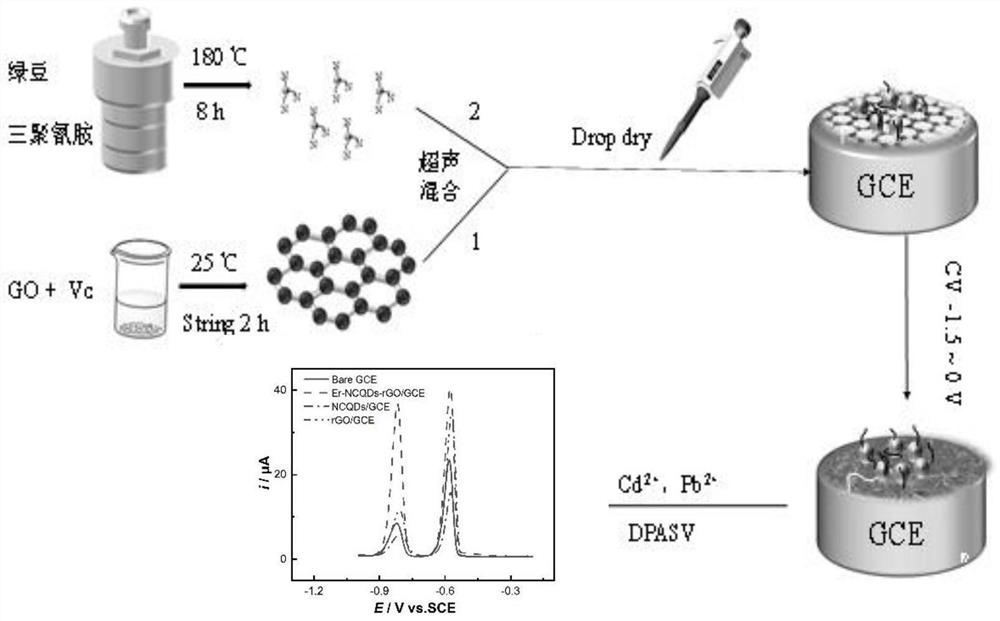

[0045]The preparation method of the nitrogen-doped carbon dots-reduced graphene oxide composite material (Er-NCQD / rGO) of the present embodiment includes the following steps:

[0046] (1) The glassy carbon electrode is polished on the chamois covered with alumina suspension, and is detected by an electrochemical workstation to obtain a qualified glassy carbon electrode for standby;

[0047] (2) First weigh 100mg of mung bean powder and 10mg of melamine in a beaker, add 50mL of distilled water and stir evenly, transfer to a polytetrafluoroethylene lining and then put into a high-pressure reactor, and put into a blast drying oven and heat to 180°C The reaction was carried out for 8 hours, and after cooling to room temperature, the liquid was filtered to obtain a brownish-yellow liquid, which was then centrifuged (8000 r / min) for 5 minutes, and the supernatant was collected, filtered and dialyzed to obtain a nitrogen-doped carbon dot solution;

[0048] (3) Weigh 2.5mg of graphene...

Embodiment 2

[0052] The preparation method of the nitrogen-doped carbon dots-reduced graphene oxide composite material (Er-NCQD / rGO) of the present embodiment includes the following steps:

[0053] (1) The glassy carbon electrode is polished on the chamois covered with alumina suspension, and is detected by an electrochemical workstation to obtain a qualified glassy carbon electrode for standby;

[0054] (2) First weigh 80mg of mung bean powder and 10mg of melamine in a beaker, add 50mL of distilled water and stir evenly, transfer to a polytetrafluoroethylene lining and put into a high-pressure reactor, and put into a blast drying oven and heat to 180°C The reaction was carried out for 8 hours, and after cooling to room temperature, the liquid was filtered to obtain a brownish-yellow liquid, and then centrifuged (8000r / min) for 5 minutes. The supernatant was collected, filtered and dialyzed to obtain a purified nitrogen-doped carbon dot solution. ;

[0055] (3) Weigh 5mg of graphene oxide...

Embodiment 3

[0059] The preparation method of the nitrogen-doped carbon dots-reduced graphene oxide composite material (Er-NCQD / rGO) of the present embodiment includes the following steps:

[0060] (1) The glassy carbon electrode is polished on the chamois covered with alumina suspension, and is detected by an electrochemical workstation to obtain a qualified glassy carbon electrode for standby;

[0061] (2) First weigh 120mg of mung bean powder and 10mg of melamine in a beaker, add 50mL of distilled water and stir evenly, transfer to a polytetrafluoroethylene lining and put into a high-pressure reactor, and put into a blast drying oven and heat to 180°C The reaction was carried out for 8 hours, and after cooling to room temperature, the liquid was filtered to obtain a brownish-yellow liquid, and then centrifuged (8000r / min) for 5 minutes. The supernatant was collected, filtered and dialyzed to obtain a purified nitrogen-doped carbon dot solution. ;

[0062] (3) Weigh 2.5mg of graphene ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com