Welding structure and welding method of foil and cover plate

A technology of welding structure and welding method, which is applied in the field of welding of foil and cover, can solve the problems of poor connection between foil and cover, easy to break, etc., so as to improve the welding surface effect, excellent welding quality, and improve production yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The welding of the foil and the cover plate in this embodiment is as follows.

[0082] Number of foil layers: 76 layers.

[0083] Welding method: Laser welding machine of model YLR-2000-SM is used for penetration welding, and a long welding seam (ie, the second welding seam 302) is directly welded on the surface of the foil 1, and the welding speed of the welding seam is 300mm / s , the welding power is 1250W, and a weld with a molten pool penetration depth of 0.45mm and a fusion width of 2.39mm is formed.

[0084] The tomographic inspection of the welded seam structure is carried out. The observation diagram of the molten pool of the welded structure, the observation diagram of the left fault, and the observation diagram of the right fault are as follows: Figure 6a , Figure 6b , Figure 6c The observation results show that there are obvious faults after welding between the molten pool, the foil and the cover plate, and the number of faults on the left and right si...

Embodiment 2

[0086] The welding of the foil and the cover plate in this embodiment is as follows.

[0087] Number of foil layers: 76 layers.

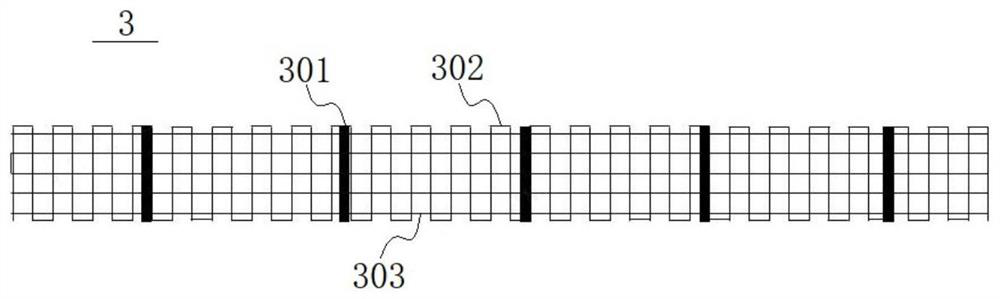

[0088] Welding method: use laser welding machine model YLR-2000-SM to penetrate through welding, and weld several first welds 301 on the surface of the foil 1; Preheat the welding seam 303 ; and then weld the second welding seam 302 on the surface of the preheating welding seam 303 .

[0089] Among them, the welding speed of the first welding seam 301 is 250mm / s, the welding power is 800W; the seam width of the first welding seam 301 is 0.4-0.6mm, the penetration depth is 0.2-0.3mm; the speed of preheating before welding is 300mm / s, the power is 1200W, the instantaneous temperature after preheating is completed is 60-120°C; the welding speed of the second welding seam 302 is 300mm / s, and the welding power is 1250W. see Figure 7 As shown, the included angle between the first welding seam 301 and the second welding seam 302 is 30°.

[0090] A ...

Embodiment 3

[0092] The welding of the foil and the cover plate in this embodiment is as follows.

[0093] Number of foil layers: 76 layers.

[0094]Welding method: use laser welding machine model YLR-2000-SM to penetrate through welding, and weld several first welds 301 on the surface of the foil 1; Preheat the welding seam 303 ; and then weld the second welding seam 302 on the surface of the preheating welding seam 303 .

[0095] Among them, the welding speed of the first welding seam 301 is 250mm / s, the welding power is 800W; the seam width of the first welding seam 301 is 0.4-0.6mm, the penetration depth is 0.2-0.3mm; the speed of preheating before welding is 300mm / s, the power is 1200W, the instantaneous temperature after preheating is completed is 60-120°C; the welding speed of the second welding seam 302 is 300mm / s, and the welding power is 1250W. see Figure 9 As shown, the included angle between the first welding seam 301 and the second welding seam 302 is 45°.

[0096] A w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com