Powder for additive manufacturing and preparation method and application thereof

A technology of additive manufacturing and powder, which is applied in the field of powder for additive manufacturing and its preparation, and can solve problems affecting the formability and mechanical properties of materials, thermal cracks of aluminum alloy parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Another embodiment of the present invention provides the above-mentioned preparation method of powder for additive manufacturing, comprising the following operation steps:

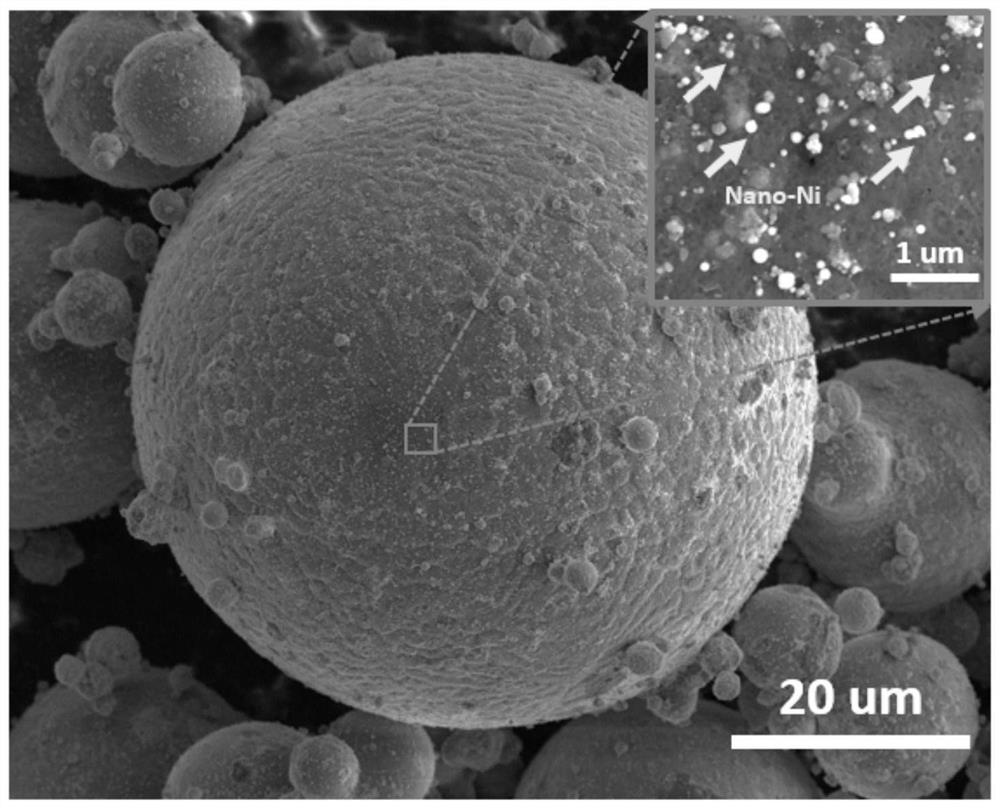

[0047] The aluminum alloy powder and the nanometer Ni powder are fully mixed, so that the nanometer Ni powder is uniformly attached to the surface of the aluminum alloy powder, and the powder for additive manufacturing is obtained;

[0048] After thorough mixing, the powders for additive manufacturing are dried under vacuum.

[0049] Another embodiment of the present invention provides the application of the powder for additive manufacturing as described above in the additive manufacturing of aluminum alloys.

[0050] In some embodiments, the method of additive manufacturing is laser additive manufacturing.

[0051] In some embodiments, the application of the additively manufactured aluminum alloy includes the following steps:

[0052] Put the powder for additive manufacturing into the selective l...

Embodiment 1

[0055] This embodiment is used to illustrate the additively manufactured aluminum alloy disclosed in the present invention and the preparation method thereof, including the following operation steps:

[0056] (1) The nanometer Ni powder with a mass fraction of 3.5% and an average particle size of about 50 nm and 7075 aluminum alloy powder with a mass fraction of 96.5% and an average particle size of about 30 μm were quickly turned in a three-dimensional rocking powder mixer. Invert and shake for 3 hours to mix well.

[0057] (2) Put the mixed powder obtained in step (1) into a vacuum drying oven, and place it at 70° C. for 12 hours for drying.

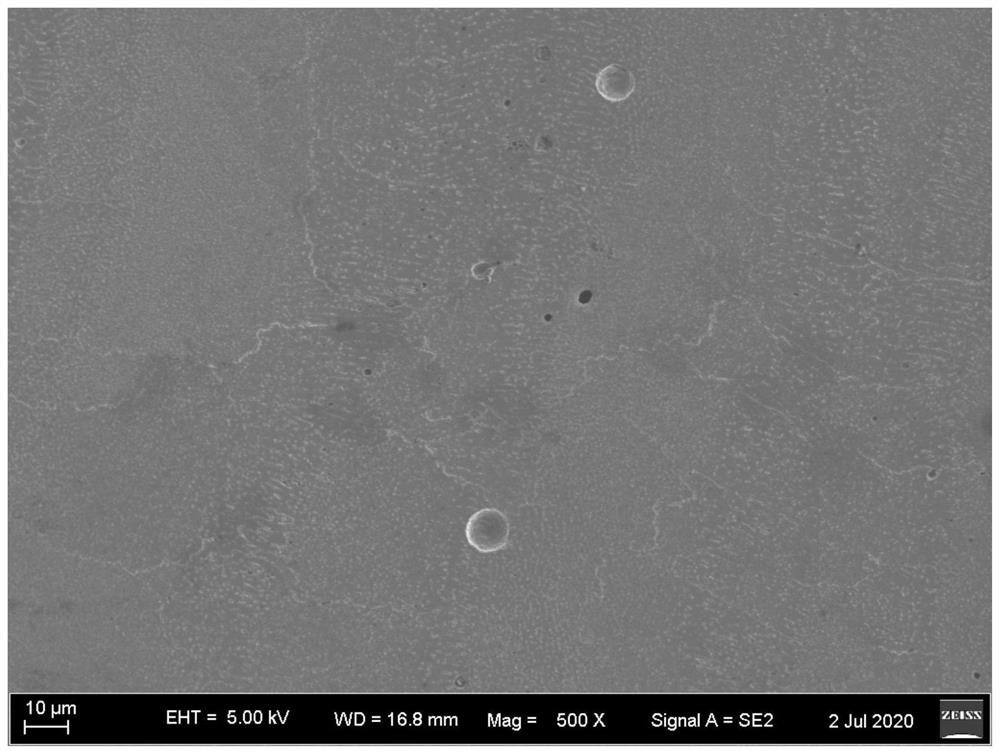

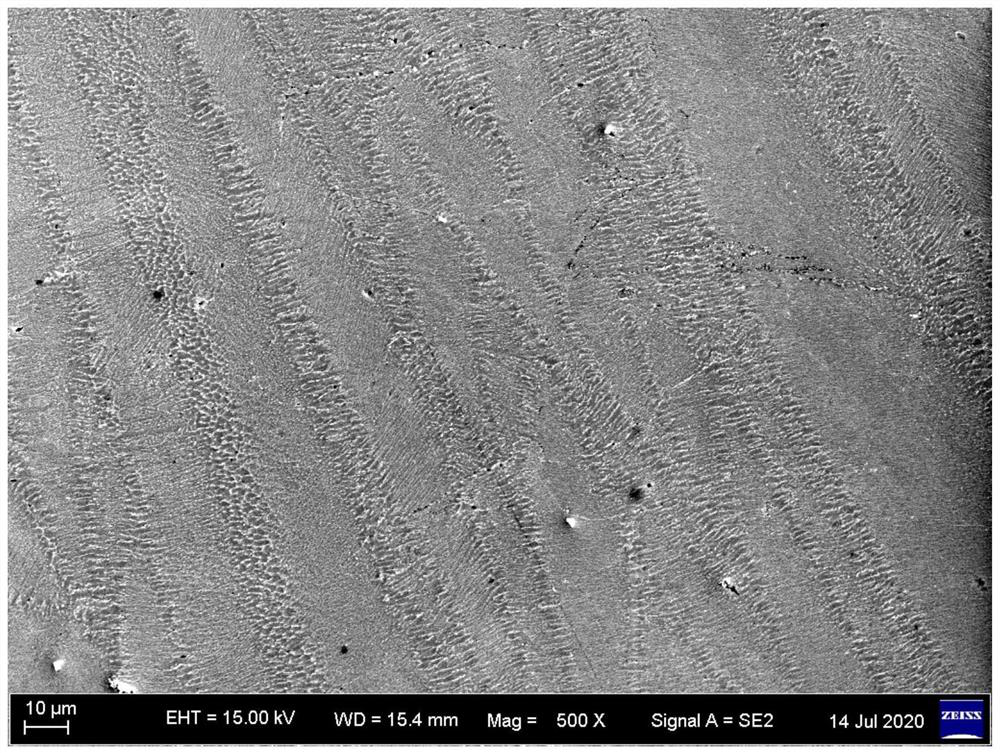

[0058] (3) Put the dried powder into the selective laser melting equipment, and shape it with a laser power of 240W, a scanning rate of 80 mm / s, a scanning distance of 100 μm, and a layer thickness of 30 μm to obtain an aluminum alloy.

Embodiment 2

[0060] This embodiment is used to illustrate the additively manufactured aluminum alloy disclosed in the present invention and the preparation method thereof, including the following operation steps:

[0061] (1) The nanometer Ni powder with a mass fraction of 5.8% and an average particle size of about 760 nm and 7075 aluminum alloy powder with a mass fraction of 94.2% and an average particle size of about 30 μm were quickly turned in a three-dimensional rocking powder mixer. Invert and shake for 3 hours to mix well.

[0062] (2) Put the mixed powder obtained in step (1) into a vacuum drying oven, and place it at 70° C. for 12 hours for drying.

[0063] (3) Put the dried powder into the selective laser melting equipment, and shape it with a laser power of 240W, a scanning rate of 60mm / s, a scanning distance of 100μm, and a layer thickness of 30μm to obtain an aluminum alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com