Prism speckle monocular real-time measurement method suitable for three-dimensional deformation

A real-time measurement, three-dimensional deformation technology, applied in the field of deformation measurement, engineering materials and optical measurement mechanics, can solve the problems of difficult optical path layout, limited application, inability to obtain full field data, etc. The effect of the small size of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

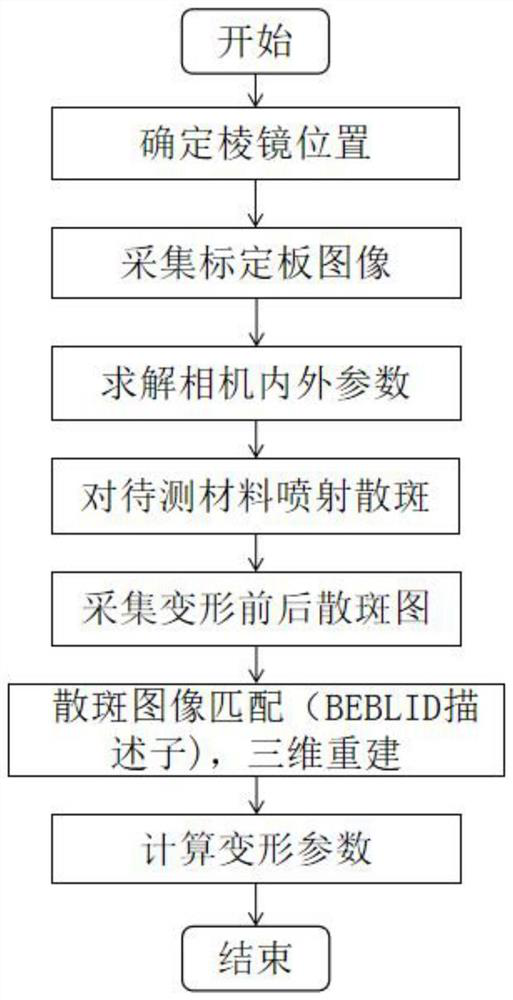

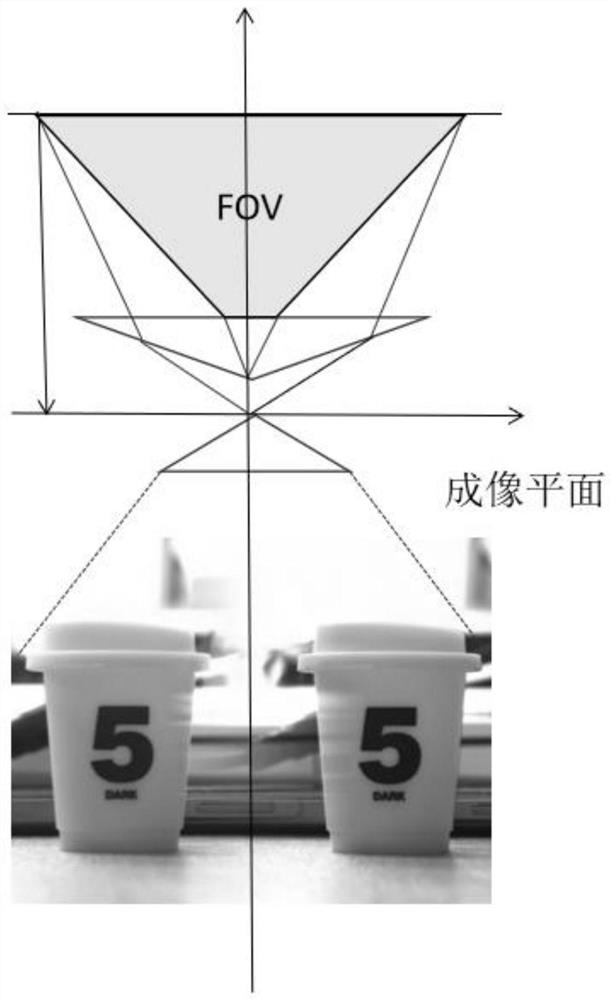

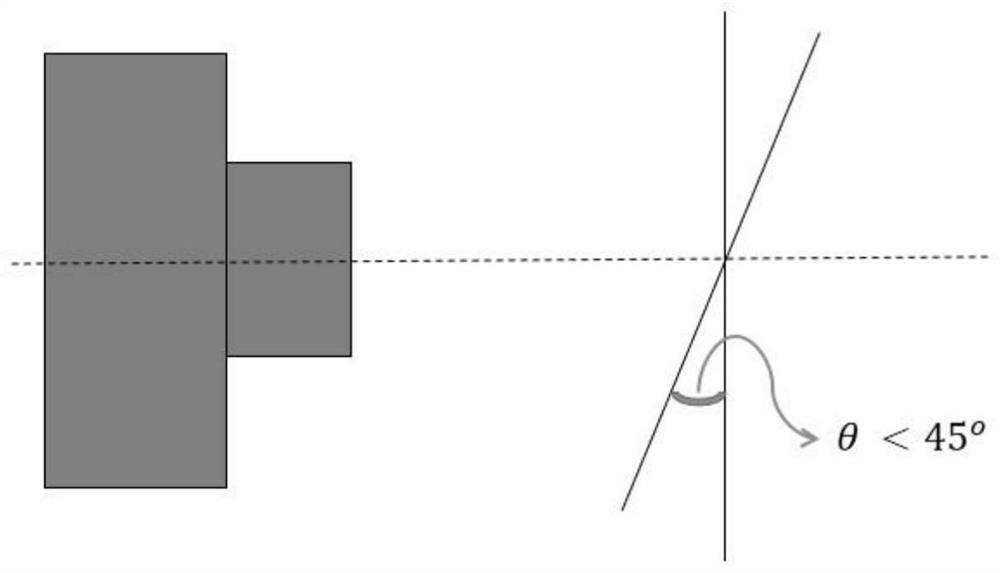

[0048] The present invention is applicable to the prism speckle monocular real-time measurement method of three-dimensional deformation, and the required measurement system includes a CCD camera, a triangular prism, a bottle of speckle self-spray paint, a checkerboard calibration board, a computer, test material. The computer includes an image acquisition control unit, an image segmentation unit and a camera parameter calibration unit, wherein the image acquisition control unit is used to control the CCD camera to acquire images; the image segmentation unit is used to perform the following steps 3 and 5; the camera parameter calibration unit uses Then execute the following step 4 to complete the calibration of the virtual binocular measurement system.

[0049] The prism speckle monocular measurement method suitable for three-dimensional defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com