Novel oil pipe joint device

A new type of oil pipe joint technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of difficult water drainage and gas recovery, weakened gas pressure, and inability to carry liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

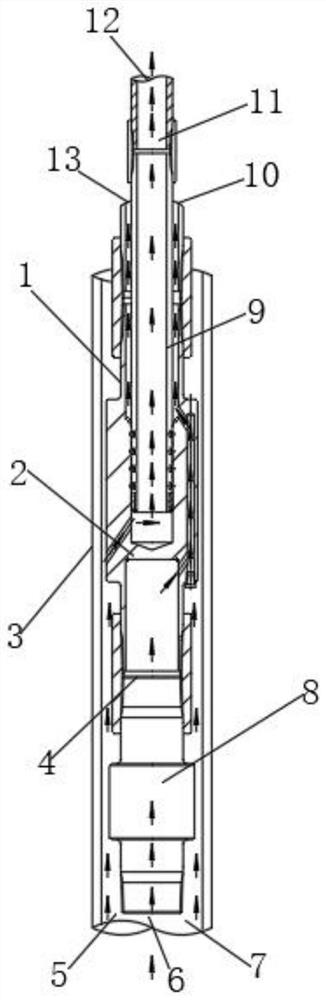

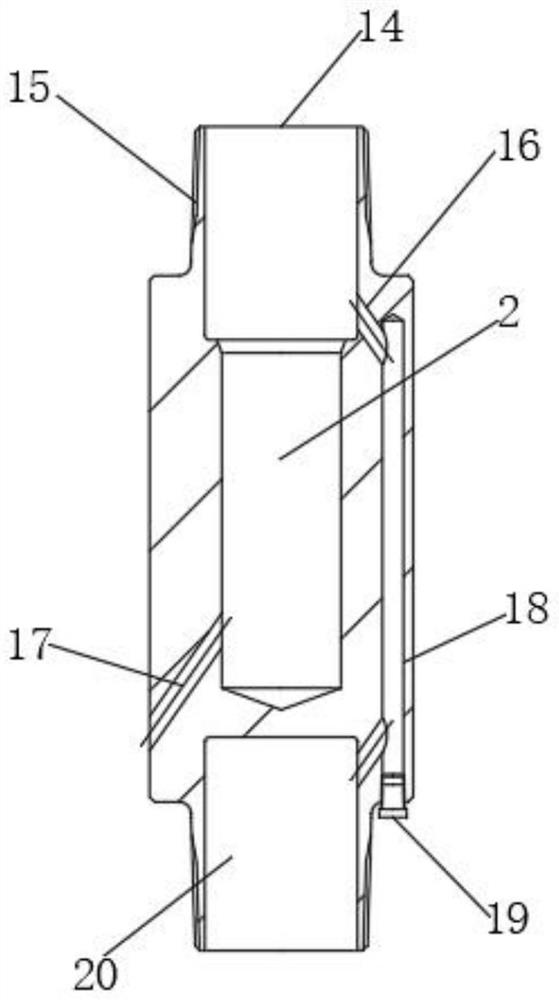

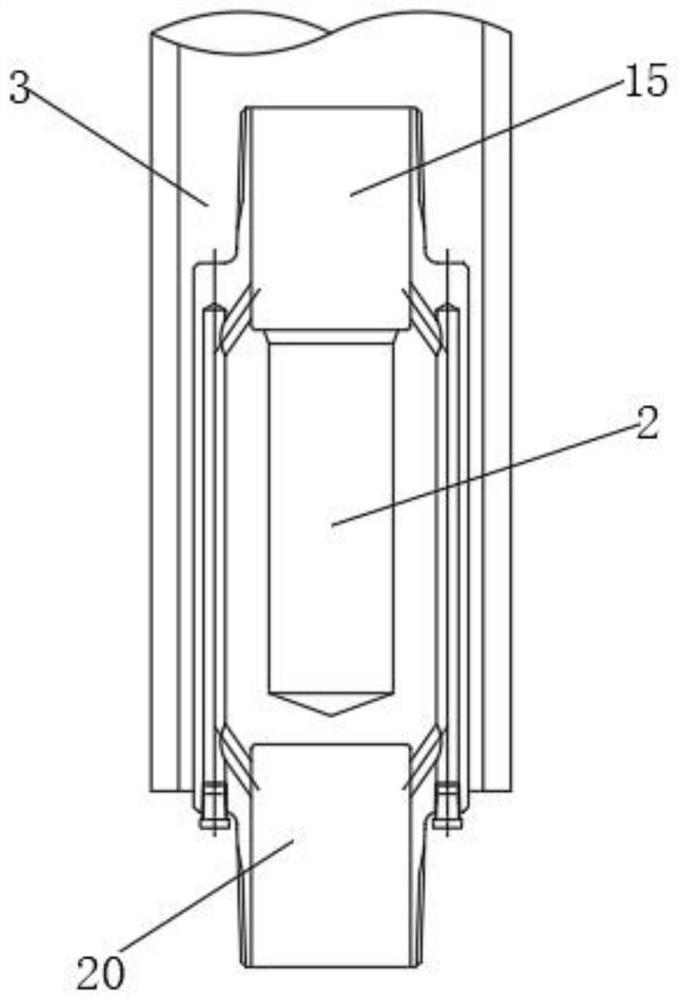

[0031] like Figure 1-5 As shown, a new type of oil pipe joint device includes an oil pipe joint main body 1, an oil cylinder 4 and a main passage hole 2 are arranged inside the oil pipe joint main body 1, an insertion rod 9 is arranged in the main passage hole 2, and an outer side of the oil pipe joint main body 1 is provided. A casing 3 is positioned, the top of the oil pipe joint body 1 is provided with a No. 1 air inlet 5, a water inlet 6 and a No. 2 air inlet 7, and the top of the oil pipe joint main body 1 is provided with a No. 1 water outlet 13 and a No. 2 water outlet 10, The top of the insertion rod 9 is provided with an air outlet 12 , and the oil cylinder 4 is provided with an electric submersible pump 8 .

[0032] Further, the bottom position of the main passage hole 2 is provided with a No. 2 inclined hole 17, the top position of the main passage hole 2 is provided with a No. A screw 19 is installed at the bottom, and an upper oil pipe thread 15 and a lower oil ...

Embodiment 2

[0036] On the basis of Example 1, as figure 1 , 6 As shown, a new type of oil pipe joint device includes an oil pipe joint main body 1, an oil cylinder 4 and a main passage hole 2 are arranged inside the oil pipe joint main body 1, an insertion rod 9 is arranged in the main passage hole 2, and an outer side of the oil pipe joint main body 1 is provided. A casing 3 is positioned, the top of the oil pipe joint body 1 is provided with a No. 1 air inlet 5, a water inlet 6 and a No. 2 air inlet 7, and the top of the oil pipe joint main body 1 is provided with a No. 1 water outlet 13 and a No. 2 water outlet 10, The top of the insertion rod 9 is provided with an air outlet 12 , and the oil cylinder 4 is provided with an electric submersible pump 8 .

[0037] Further, when only water is produced and the well contains no gas, the input end of the oil cylinder 4 is provided with a water inlet groove 30 , and the output end of the oil cylinder 4 is provided with a water outlet groove 2...

Embodiment 3

[0039] On the basis of Example 1, as figure 1 , 7 As shown, a new type of oil pipe joint device includes an oil pipe joint main body 1, an oil cylinder 4 and a main passage hole 2 are arranged inside the oil pipe joint main body 1, an insertion rod 9 is arranged in the main passage hole 2, and an outer side of the oil pipe joint main body 1 is provided. The casing 3 is positioned, the top of the oil pipe joint main body 1 is provided with a No. 1 air inlet 5, a water inlet 6 and a No. 2 air inlet 7, and the top of the oil pipe joint main body 1 is provided with a No. 1 water outlet 13 and a No. 2 water outlet 10, The top of the insertion rod 9 is provided with an air outlet 12 , and the oil cylinder 4 is provided with an electric submersible pump 8 .

[0040] Further, what is transported is gas production, the formation pressure is very high, and there is a small amount of water in the well, and the gas can carry liquid to carry the water out of the wellhead. The water vapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com