Nano micro-water car washing stock solution and preparation method thereof

A micro-water and car washing technology, applied in the field of car washing liquid, can solve the problems of large investment in environmental protection equipment, increased costs, waste of water resources, etc., and achieve the effect of easy control of process parameters and stable and balanced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

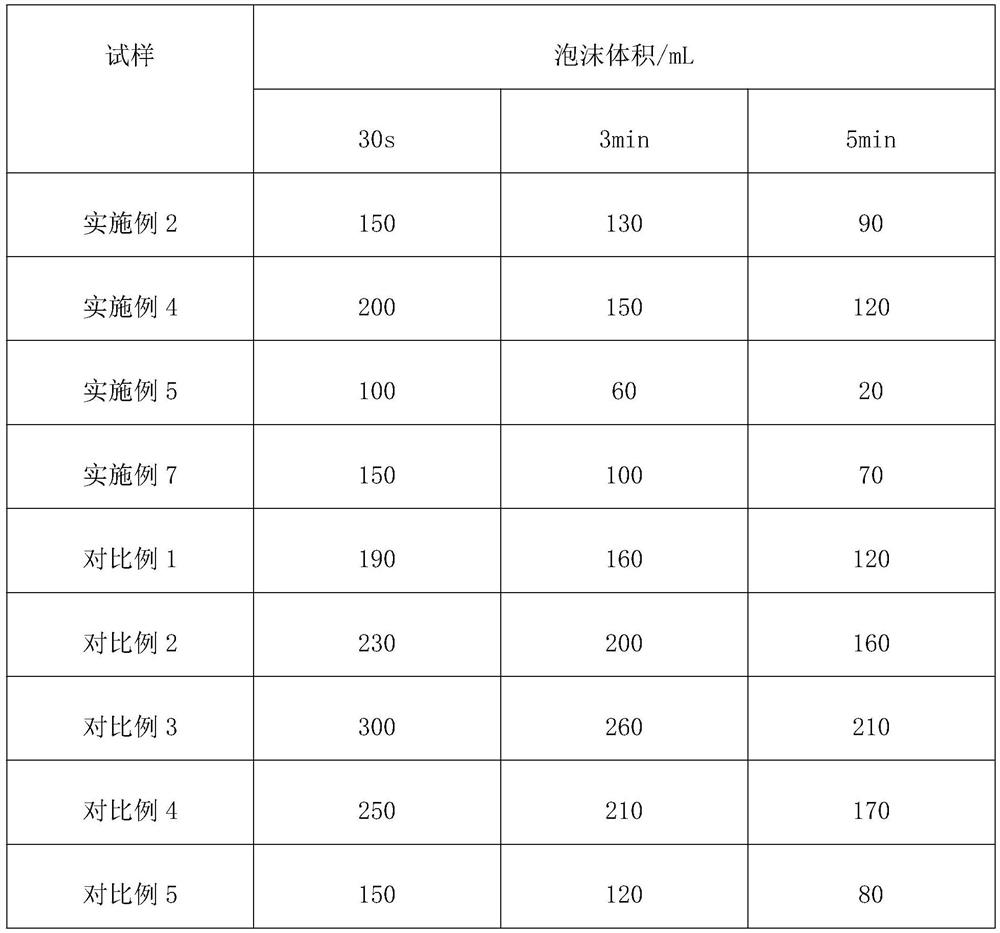

Examples

preparation example Construction

[0025] The present invention also provides a method for preparing a nano-micro water car washing stock solution, comprising the following steps:

[0026] Take part of water and add modified oil ethoxylate, fatty alcohol polyoxyethylene ether carboxylic acid, alkyl alcohol amide, α-sulfonated fatty acid methyl ester salt and sophorolipid, and stir at constant temperature to obtain mixture 1;

[0027] Take part of water and add polyacrylate, corrosion inhibitor, stabilizer, scale inhibitor and ultraviolet absorber, and stir at constant temperature to obtain mixture 2;

[0028] Mix the mixture 1 and the mixture 2 uniformly, add the defoaming agent and the remaining water, and stir to obtain the nano-micro water car washing stock solution. In the preparation steps of the present invention, process parameters are easy to control, large-scale production is possible, and the performance of the prepared car washing stock solution is stable and balanced.

[0029] In some embodiments o...

Embodiment 1

[0034] A method for preparing a nano-micro water car washing stock solution, comprising the following steps:

[0035] Raw materials: modified oil ethoxylate 3%, fatty alcohol polyoxyethylene ether carboxylic acid 2%, alkyl alcohol amide 1%, α-sulfonated fatty acid methyl ester salt 1%, sophorolipid 1%, polyacrylate 0.5%, defoaming agent (methyl silicone oil) 0.2%, corrosion inhibitor (octadecyl ammonium phosphate) 0.3%, stabilizer (calcium xylene sulfonate) 0.2%, scale inhibitor (sodium carbonate) 1 %, ultraviolet absorber (ethylhexyl triazinone) 0.3%, and the balance is water.

[0036] Take part of the water and add modified oil ethoxylate, fatty alcohol polyoxyethylene ether carboxylic acid, alkyl alcohol amide, α-sulfonated fatty acid methyl ester and sophorolipid, and stir at a constant temperature of 35 ° C and 500 rpm for 30 min , to obtain mixture 1;

[0037] Take part of the water and add polyacrylate, corrosion inhibitor, stabilizer, scale inhibitor and ultraviolet ...

Embodiment 2

[0040] A method for preparing a nano-micro water car washing stock solution, comprising the following steps:

[0041] Raw materials: modified oil ethoxylate 5%, fatty alcohol polyoxyethylene ether carboxylic acid 4%, alkyl alcohol amide 2%, α-sulfonated fatty acid methyl ester salt 2%, sophorolipid 2%, polyacrylate 0.8%, defoaming agent (methyl silicone oil) 0.4%, corrosion inhibitor (octadecyl ammonium phosphate) 0.5%, stabilizer (calcium xylene sulfonate) 0.4%, scale inhibitor (sodium carbonate) 1.5 %, ultraviolet absorber (ethylhexyl triazinone) 0.8%, and the balance is water.

[0042] Take part of the water and add modified oil ethoxylate, fatty alcohol polyoxyethylene ether carboxylic acid, alkyl alcohol amide, α-sulfonated fatty acid methyl ester salt and sophorolipid, and stir at a constant temperature of 45 ° C and 600 rpm for 40 min , to obtain mixture 1;

[0043] Take part of the water, add polyacrylate, corrosion inhibitor, stabilizer, scale inhibitor and ultravio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com