Preparation method of inorganic fiber toughening agent for oil and gas well cementing slurry

A technology of cementing cement slurry and inorganic fiber, which is applied in the field of oil and gas drilling and completion engineering, and can solve the problems of cement stone resistance to cyclic load performance, obvious thickening effect of magnesium carbonate whiskers, cement stone elastic modulus, etc. problem, to achieve low elastic modulus, good compressive and flexural strength, and enhanced bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

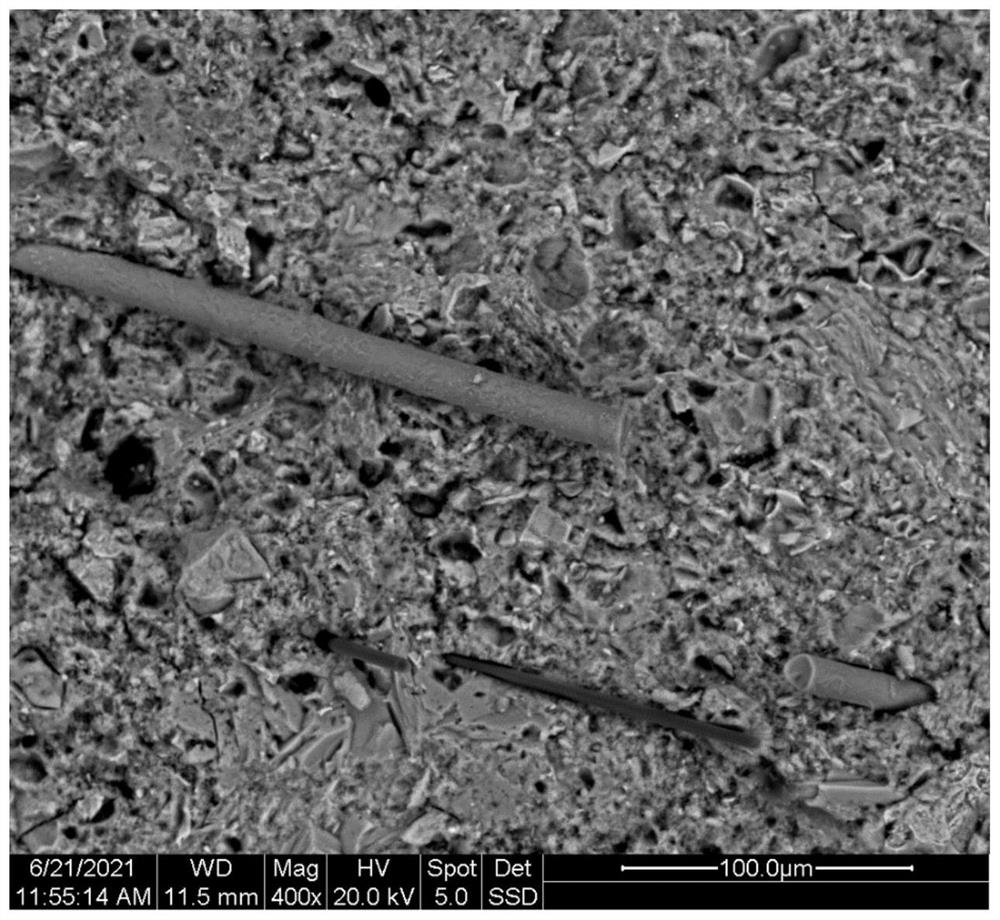

[0023] as Figure 1 The present invention provides a method for preparing an inorganic fiber toughener for cementing cementing cementitious cementitious in oil and gas wells, comprising the following steps:

[0024] (1) Single fiber "stirring-ultrasonic" pretreatment process

[0025] Basalt fibers, carbon fibers, magnesium fibers and silicon carbide fibers are placed in a high-speed stirrer containing deionized water, and the amount of corresponding fibers added to each high-speed stirrer is 5 to 15% of the mass of deionized water;

[0026] Under conditions greater than 10000 rpm, stir for 15-30 minutes;

[0027] The fibers in the deionized water were dispersed by ultrasonic waves for 30 minutes.

[0028] Filtration, washing, drying, standby;

[0029] (2) A variety of fibers "suspension - stirring" mixing process

[0030] One or more of the pretreated basalt fibers, carbon fibers, magnesium fibers, and silicon carbide fibers are added to deionized water in a preset proportion, and ...

Embodiment 1

[0040] The relevant process parameters for the preparation of inorganic fiber tougheners for cementing cementing cement slurry in oil and gas wells are as follows:

[0041] (1) Single fiber "stirring-ultrasonic" pretreatment process

[0042] Mass ratio of pretreated fibers to deionized water: 5%.

[0043] Pretreatment speed: 10,000 rpm.

[0044] Mixing time: 20 minutes.

[0045] Ultrasonic processing time: 30 minutes.

[0046] (2) A variety of fibers "suspension - stirring" mixing process

[0047] Basalt Fiber: Carbon Fiber: Magnesiite Fiber: Silicon Carbide Fiber Mass Ratio = 3:3:1:1.

[0048] Stirring speed: 3000 rpm.

[0049] Mixing time: 150 minutes.

[0050] (3) Mechanical roughening process of a variety of fiber surfaces

[0051] Grinding time: 5 minutes.

[0052] (4) Fiber surface modification process

[0053] Water bath temperature: 75 °C.

[0054] Nano silica solution concentration: 30% mass fraction.

[0055] Stirring speed: 2000 rpm.

[0056] Mixing time: 25 minutes.

[0...

Embodiment 2

[0068] The relevant process parameters for the preparation of inorganic fiber tougheners for cementing cementing cement slurry in oil and gas wells are as follows:

[0069] (1) Single fiber "stirring-ultrasonic" pretreatment process

[0070] Mass ratio of pretreated fibers to deionized water: 10%.

[0071] Pretreatment speed: 12000 rpm.

[0072] Mixing time: 25 minutes.

[0073] Ultrasonic processing time: 30 minutes.

[0074] (2) A variety of fibers "suspension - stirring" mixing process

[0075] Basalt Fiber: Carbon Fiber: Magnesiite Fiber: Silicon Carbide Fiber Mass Ratio = 2:4:1:1.

[0076] Stirring speed: 3000 rpm.

[0077] Mixing time: 180 minutes.

[0078] (3) Mechanical roughening process of a variety of fiber surfaces

[0079] Grinding time: 6 minutes.

[0080] (4) Fiber surface modification process

[0081] Water bath temperature: 75 °C.

[0082] Nano silica solution concentration: 35% mass fraction.

[0083] Stirring speed: 2200 rpm.

[0084] Mixing time: 30 minutes.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drying time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com