Water-soluble biomass derived carbon dots as well as preparation method and application thereof

A biomass and water-soluble technology, applied in botany equipment and methods, chemicals for biological control, applications, etc., can solve problems such as negative impact on crop yield and quality, hindering crop growth, hindering industrial application, etc. Achieve the effect of alleviating the low iron stress of plants, excellent biological characteristics, and improving plant stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

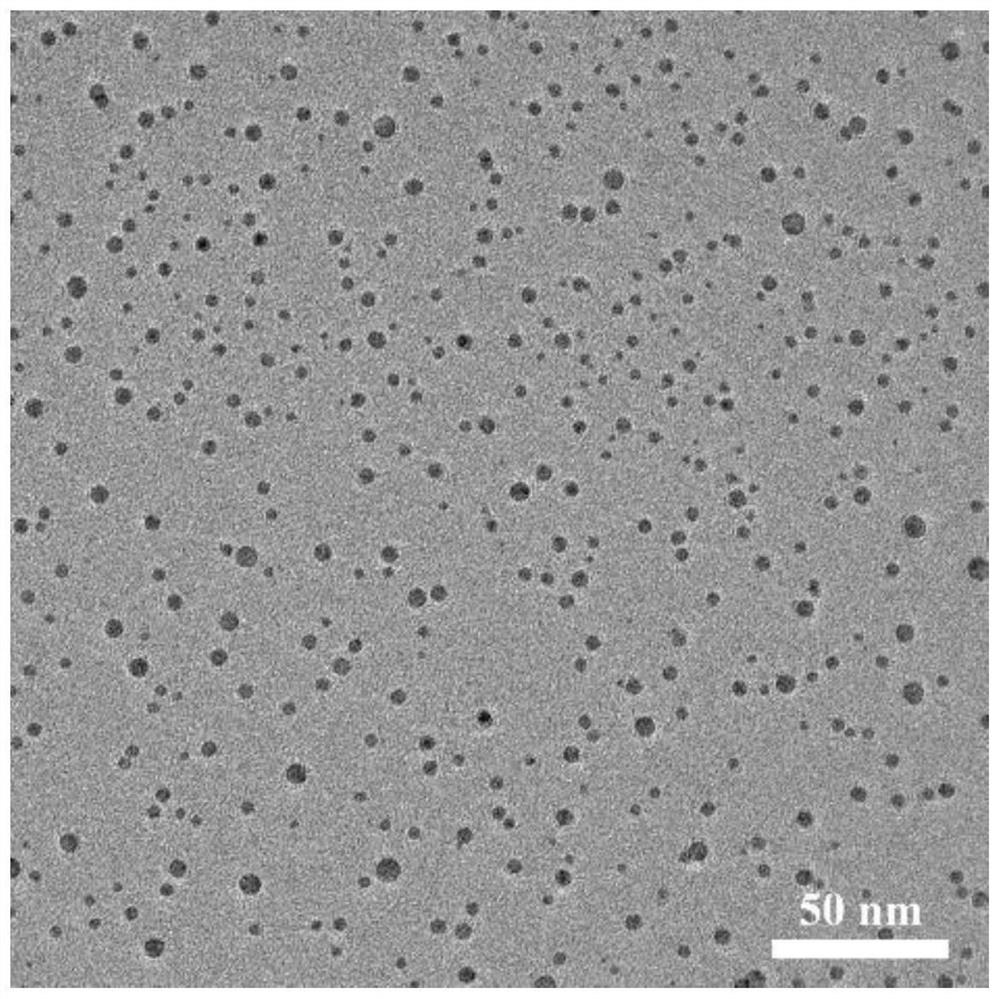

Image

Examples

Embodiment 1

[0037] Weigh 6.0g of Salvia miltiorrhiza powder and evenly disperse in 60mL of distilled water, stir at room temperature for 10min, then place the suspension in an autoclave, react at 100°C for 4h to form a carbon dot solution, and cool the formed carbon dot solution to room temperature The dialysis is carried out by using water-based microporous membrane filtration and dialysis bag respectively. The pore size of the water-based microporous membrane is 0.22 μm, and the molecular weight of the dialysis bag is 3500 Da. After removing impurities, pure water-soluble biomass-derived carbon dots are obtained, and the yield is about 20%.

Embodiment 2

[0039] Weigh 3.0g of Salvia miltiorrhiza powder and evenly disperse in 60mL of distilled water, stir at room temperature for 10min, then place the suspension in an autoclave, react at 120°C for 6h to form a carbon dot solution, and cool the formed carbon dot solution to room temperature The dialysis is carried out by using water-based microporous membrane filtration and dialysis bag respectively. The pore size of the water-based microporous membrane is 0.22 μm, and the molecular weight of the dialysis bag is 3500 Da. After removing impurities, pure water-soluble biomass-derived carbon dots are obtained, and the yield is about was 27%.

Embodiment 3

[0041] Weigh 3.0g of Salvia miltiorrhiza powder and evenly disperse in 60mL of distilled water, stir at room temperature for 10min, then place the suspension in an autoclave, react at 150°C for 6h to form a carbon dot solution, and cool the formed carbon dot solution to room temperature The dialysis is carried out by using water-based microporous membrane filtration and dialysis bag respectively. The pore size of the water-based microporous membrane is 0.22 μm, and the molecular weight of the dialysis bag is 3500 Da. After removing impurities, pure water-soluble biomass-derived carbon dots are obtained, and the yield is about 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com