Broken bridge hollow glass and manufacturing method thereof

A technology for glass and broken bridges, applied in parallel glass structures, buildings, building components, etc., can solve the problems of window sill wall damage, waste of manpower, material and financial resources, and dew condensation on insulating glass, which is beneficial to The effect of mechanization, reducing building energy consumption and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

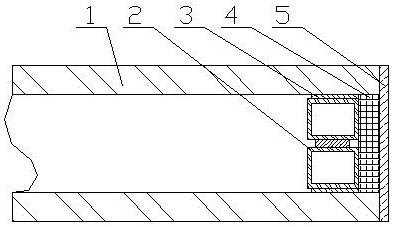

[0062] Example 1: Reference figure 1 , a broken bridge spacer can not only greatly improve the heat insulation performance of the spacer, but also greatly improve its mechanical properties.

Embodiment 2

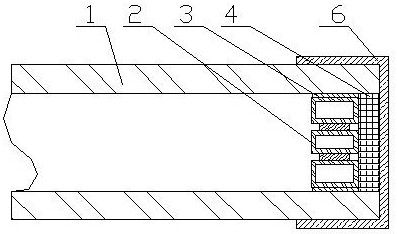

[0063] Example 2: Reference figure 2 , a broken bridge spacer, comprising the lower part 21 of the spacer, the upper part 22 of the spacer, the middle part 23 of the spacer and the connector 24 of the spacer, which is basically the same as in embodiment 1, except that the The middle part 23 of the spacer and the connecting piece 24 of the spacer are divided into two parts, so that the thermal insulation and mechanical properties of the spacer of the broken bridge are further improved.

Embodiment 3

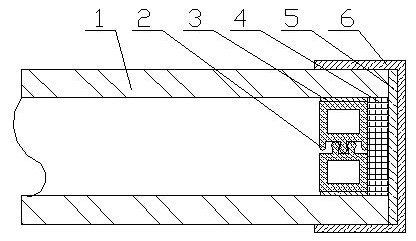

[0064] Example 3: Reference image 3 , a broken bridge spacer, including the lower part 21 of the spacer and the upper part 22 of the spacer, which is basically the same as in embodiment 1, except that the lower part 21 of the spacer and the upper part 22 of the spacer pass through the convex-concave structure Connection, the two are cross-connected, but there are only three points (lines) at the contact point, which further improves the thermal insulation performance and mechanical properties of the broken bridge spacer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com