Silk yarn elasticizing oiling agent and preparation method thereof

A silk thread and oil agent technology is applied in the field of silk thread elasticizing oil agent and its preparation, which can solve the problems of increased production cost, poor antistatic effect, affecting production efficiency, etc. cumulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

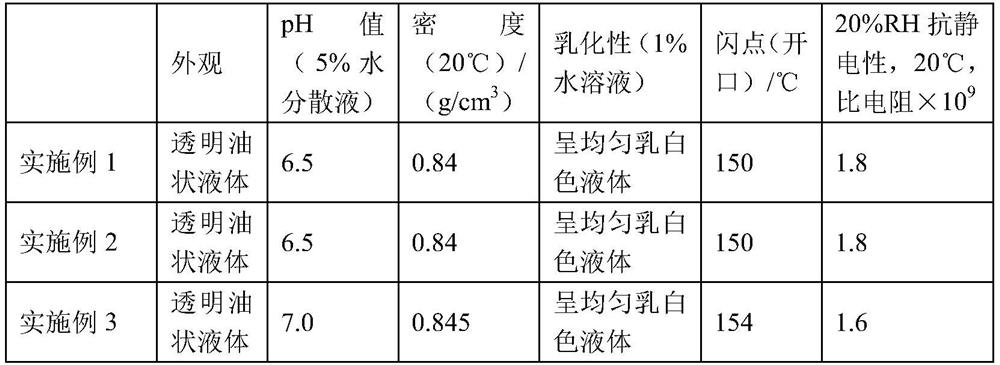

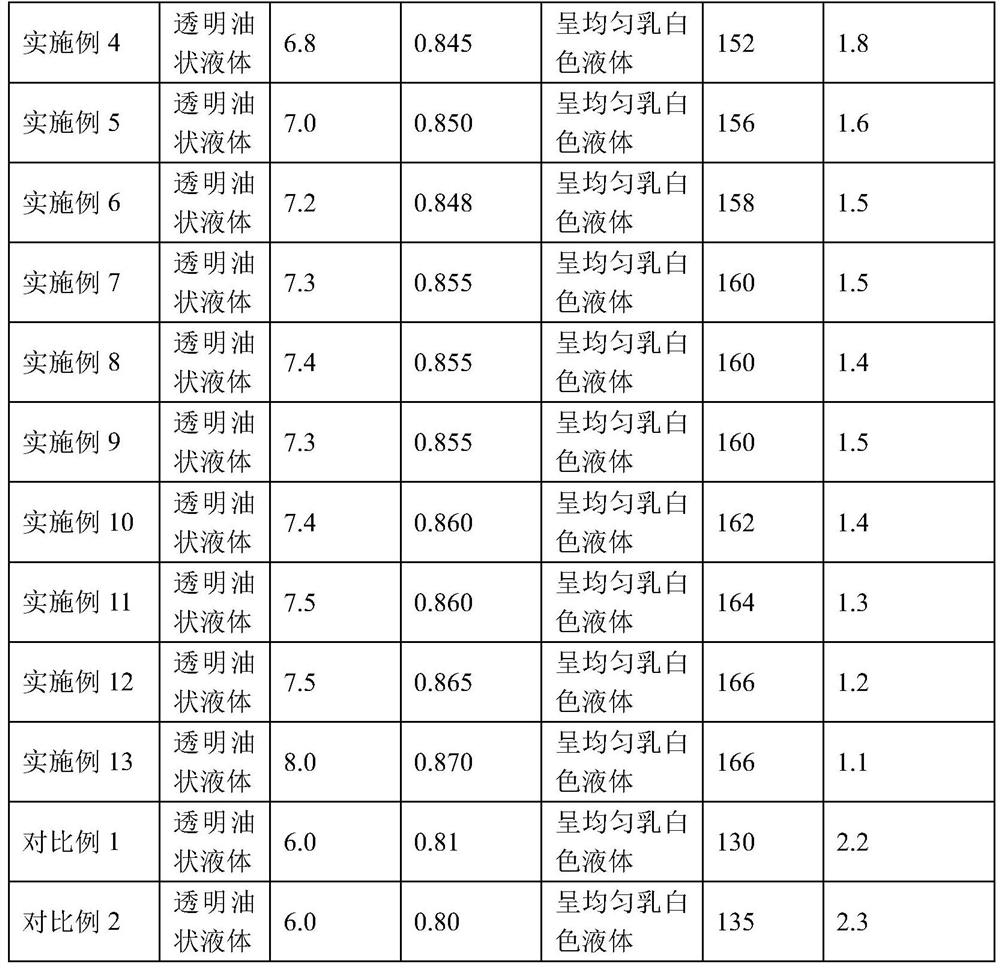

Examples

preparation example 1-3

[0034] A kind of antistatic agent of preparation example 1-3, its each raw material and each raw material consumption are as shown in table 1, and its preparation steps are as follows:

[0035] S1: react fatty alcohol with epichlorohydrin to prepare fatty alcohol polyoxyethylene ether;

[0036] S2: Fatty alcohol polyoxyethylene ether reacts with phosphorus pentoxide to prepare fatty alcohol polyoxyethylene ether phosphate;

[0037] S3: Fatty alcohol polyoxyethylene ether phosphate and epichlorohydrin synthesis alkanes to synthesize fatty alcohol polyoxyethylene ether phosphate polyoxyethylene ester; S4: Fatty alcohol polyoxyethylene ether phosphate polyoxyethylene ester and potassium hydroxide to synthesize fatty alcohol Potassium polyoxyethylene ether phosphate, antistatic agent.

[0038] Wherein, the fatty alcohol is a low carbon number fatty alcohol.

[0039] A kind of raw material of antistatic agent of table 1 preparation example 1-3 and each raw material consumption (k...

preparation example 4

[0042] An antistatic agent differs from Preparation Example 2 in that the fatty alcohol is a medium-carbon fatty alcohol, and the rest of the steps are the same as Preparation Example 2.

preparation example 5

[0044] An antistatic agent differs from Preparation Example 2 in that the fatty alcohol is a high-carbon fatty alcohol, and the rest of the steps are the same as Preparation Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com