Organic enhanced alkali lignin/SBS (styrene-butadiene-styrene) composite modifier as well as preparation method and application thereof

A composite modifier and alkali lignin technology, applied in the field of asphalt processing, can solve the problems of depletion of industrial synthetic modifier raw materials, pollution treatment and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

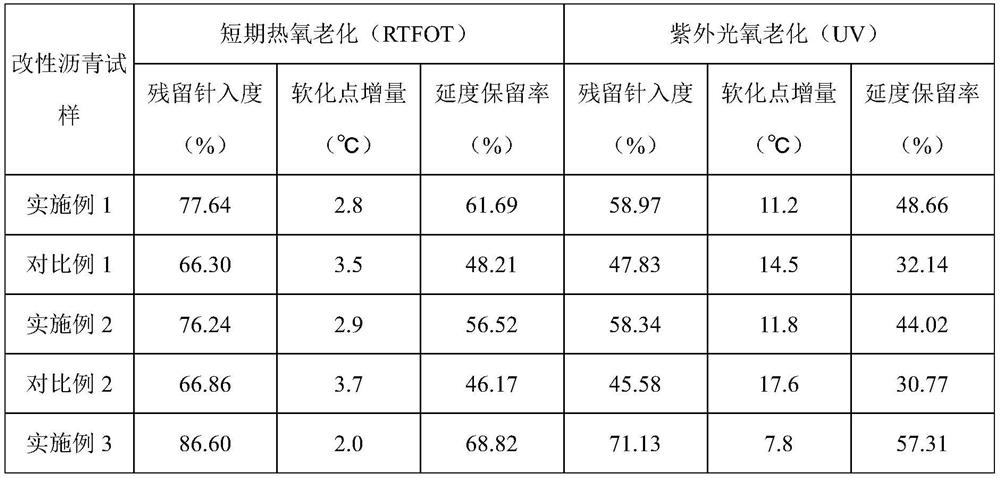

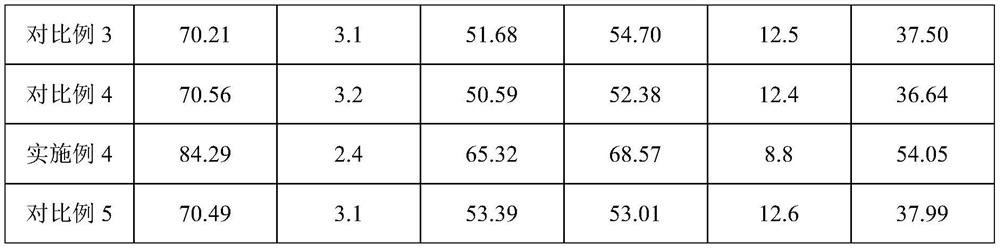

Examples

Embodiment 1

[0031] The present embodiment provides an organically enhanced soda lignin / SBS composite modifier, in terms of mass fraction, consisting of the following raw materials: 24% organically enhanced solix, 62.6% SBS, 0.4% tetrasulfide bis (1,5-pentyl) Tyrrum, 13% catalytic oil slurry; the preparation method of the organically enhanced sognin comprises the following steps:

[0032] S1, the 4,4'-diphenylmethane diisocyanate, cyclohexylamine and tetrahydrofuran were mixed according to the mass ratio of 5:2:43, stirred at 50 °C for 1h to give solution A; the alkali lignin and tetrahydrofuran were mixed according to the mass ratio 10:90, and the reaction was stirred at 60 °C for 1h to give solution B;

[0033] S2, under the protection of nitrogen, the solution A and the solution B are mixed according to the mass ratio 1:3, stirred at 60 ° C for 5h; after the reaction is over, decompression is filtered, the filter cake is washed with deionized water 3 times and then washed 3 times with tol...

Embodiment 2

[0042] The organically enhanced solyda / SBS composite modifier provided in the present embodiment, in terms of mass fraction, consists of the following raw materials: 20% organically enhanced solix, 67.7% SBS, 0.3% tetramethylcholamm disulfide, 12% catalytic oil slurry;

[0043] The preparation method of the organically enhanced alkali lignin comprises the following steps:

[0044] S1, the 2,4'-diphenylmethane diisocyanate, cyclohexylamine and tetrahydrofuran according to the mass ratio of 10: 5: 85 mixed, stirred at 45 ° C for 2h, to give solution A; the alkali lignin and tetrahydrofuran were mixed according to the mass ratio of 20:80, stirred at 55 ° C for 2h, to give solution B;

[0045]S2, under the protection of nitrogen, the solution A and the solution B are mixed according to the mass ratio 1:4, stirred at 55 ° C for 6h; after the end of the reaction, decompression filtration, filter cake washed with deionized water 5 times and then washed with toluene 5 times, and then fi...

Embodiment 3

[0052] The organically enhanced solydain / SBS composite modifier provided in the present embodiment, in terms of mass fraction, consists of the following raw materials: 30% organically enhanced soled lignin, 54.5% SBS, 0.5% tetraethyl thirulam disulfide, 15% catalytic oil slurry;

[0053] The preparation method of the organically enhanced alkali lignin comprises the following steps:

[0054] S1, the 2,2'-diphenylmethane diisocyanate, cyclohexylamine and tetrahydrofuran were mixed according to the mass ratio of 10:6:84, stirred at 48 °C for 1.5h to give solution A; the alkali lignin was mixed with the tetrahydrofuran according to the mass ratio of 15:85, stirred at 57 °C for 1.5h, to give solution B;

[0055]S2, under the protection of nitrogen, the solution A and the solution B are mixed according to the mass ratio of 3:7, stirred at 58 ° C for 4h; after the reaction is over, decompression is filtered, the filter cake is washed with deionized water 4 times and then washed with to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com