Super-hydrophobic hollow MOFs modified hollow fiber composite membrane and application thereof

A fiber composite and super-hydrophobic technology, applied in fiber treatment, synthetic fiber, membrane technology, etc., can solve the problems of low microporosity and poor hydrophobicity, and achieve the goal of improving hydrophobicity, improving microporosity and reducing mass transfer resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of ZIF-8: Prepare 100mL ZnCl respectively 2 Methanol solution (1mol / L) and 2-methylimidazole (2mol / L) methanol solution, and then they were uniformly mixed under the condition of stirring, left to stand at room temperature for 24h, centrifugal methanol washing and drying, to obtain ZIF- 8 materials.

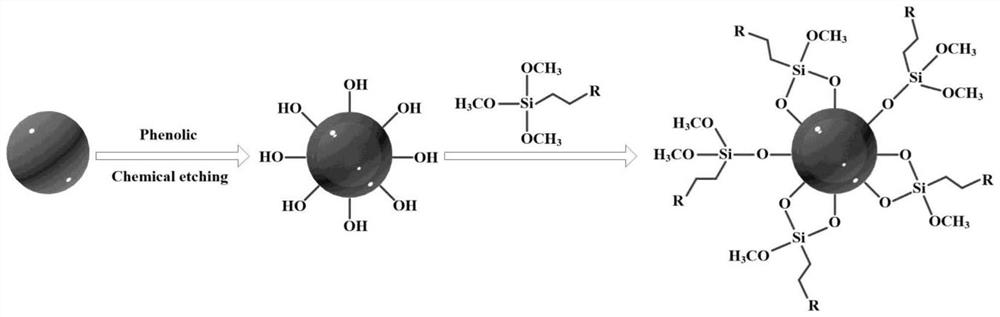

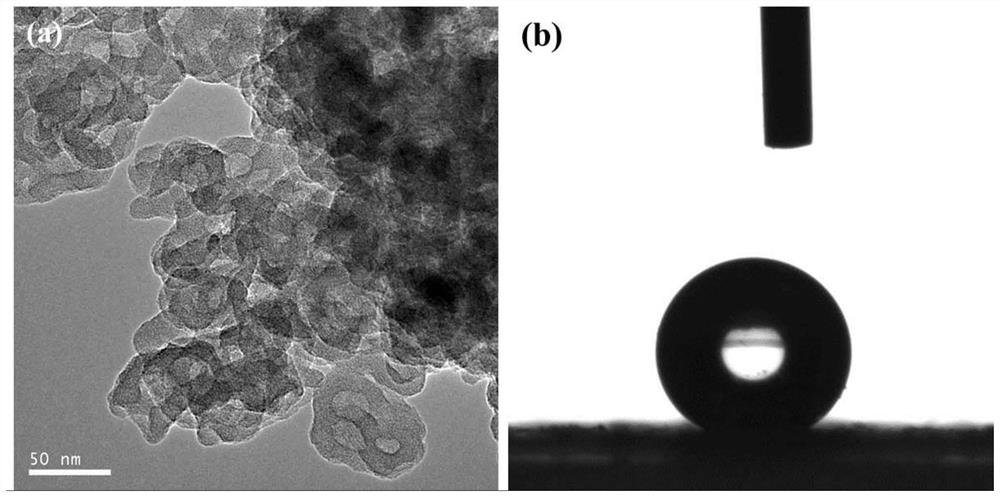

[0034] (2) Preparation of super-hydrophobic hollow ZIF-8: disperse the ZIF-8 material in 30mL water by ultrasonic stirring to obtain a 10mg / mL ZIF-8 dispersion, and then add 30mL 3mg / mL tea polyphenols aqueous solution, Stir for 5 minutes, then centrifuge, wash with methanol and hexane in turn, then redisperse it in 30mL of hexane, add 1mL (0.89g) of n-dodecyltrimethoxysilane, and stir the reaction at 80°C for 24h. Centrifuge, wash with hexane, and dry to obtain a super-hydrophobic hollow ZIF-8 material.

[0035] (3) Super-repellent hollow ZIF-8 modified hollow fiber composite membrane and components: PS polymer hollow fiber is used as the supporting memb...

Embodiment 2

[0039] (1) Preparation of ZIF-7: Prepare 100mL ZnCl respectively 2methanol solution (1mol / L) and benzimidazole (2mol / L) methanol solution, and then mix them uniformly under the condition of stirring, stand at room temperature for 24h, centrifuge methanol washing and drying to obtain ZIF-7 material .

[0040] (2) Preparation of super-hydrophobic hollow ZIF-7: disperse the ZIF-7 material in water by ultrasonic stirring to obtain a 10 mg / mL ZIF-7 dispersion, then add 30 mL of 3 mg / mL tea polyphenol aqueous solution, and stir 5min, then centrifuged, washed with methanol and hexane in turn, then dispersed in 30mL of hexane again, added 1mL (0.89g) n-dodecyltrimethoxysilane, stirred at 80°C for 24h, centrifuged Wash and dry with hexane to obtain super-hydrophobic hollow ZIF-7 material.

[0041] (3) Super-repellent hollow ZIF-7 modified hollow fiber composite membrane and components: PS polymer hollow fiber is used as the supporting membrane (molecular weight cut-off 60,000, Tianji...

Embodiment 3

[0044] (1) Preparation of ZIF-67: Prepare 100mL CoCl respectively 2 Methanol solution (1mol / L) and 2-methylimidazole (2mol / L) methanol solution, and then they were uniformly mixed under the condition of stirring, left to stand at room temperature for 24h, centrifugal methanol washing and drying, to obtain ZIF- 67 materials.

[0045] (2) Preparation of super-hydrophobic hollow ZIF-67: disperse the ZIF-67 material in water by ultrasonic stirring to obtain a 10mg / mL ZIF-67 dispersion, then add 30mL of 3mg / mL tea polyphenol aqueous solution and stir for 5min , then centrifuged, washed with methanol and hexane in turn, and then dispersed in 30mL of hexane again, after adding 1mL (0.89g) of n-dodecyltrimethoxysilane, stirred at 80°C for 24h, centrifuged The super-hydrophobic ZIF-67 material was obtained by washing and drying with alkane.

[0046] (3) Super-repellent hollow ZIF-67 modified hollow fiber composite membrane and components: PS polymer hollow fiber is used as the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com