Preparation method and application of carbon-based catalyst with high-breathability porous structure

A carbon-based catalyst and initiator technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of large-scale development and application in the battery field, high cost, expression, etc., and achieve excellent oxygen reduction and oxygen evolution performance, The effect of high breathability and high breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

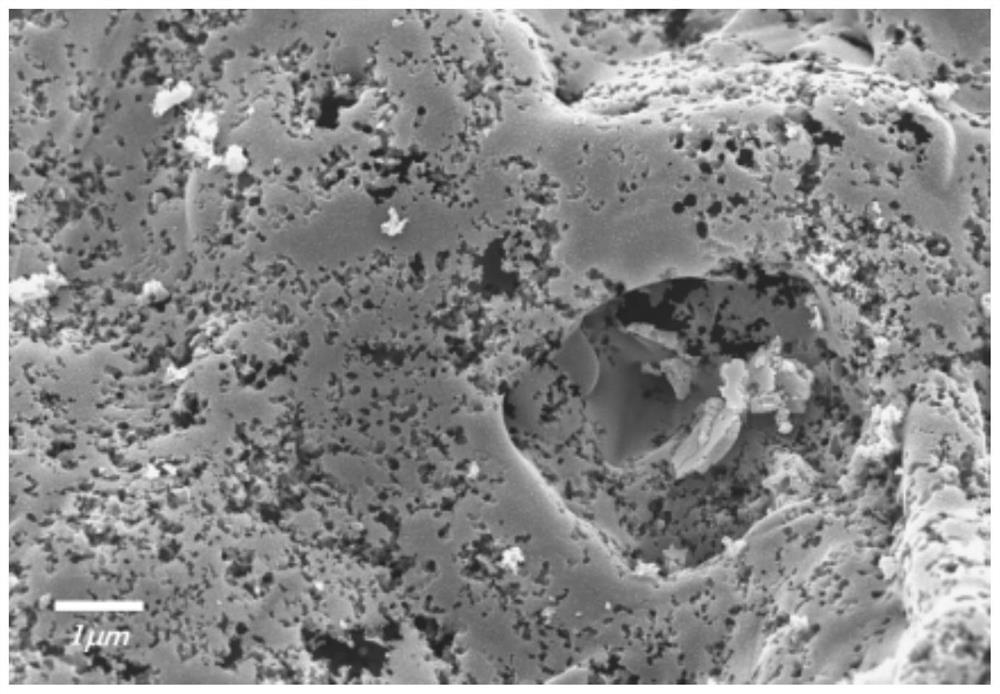

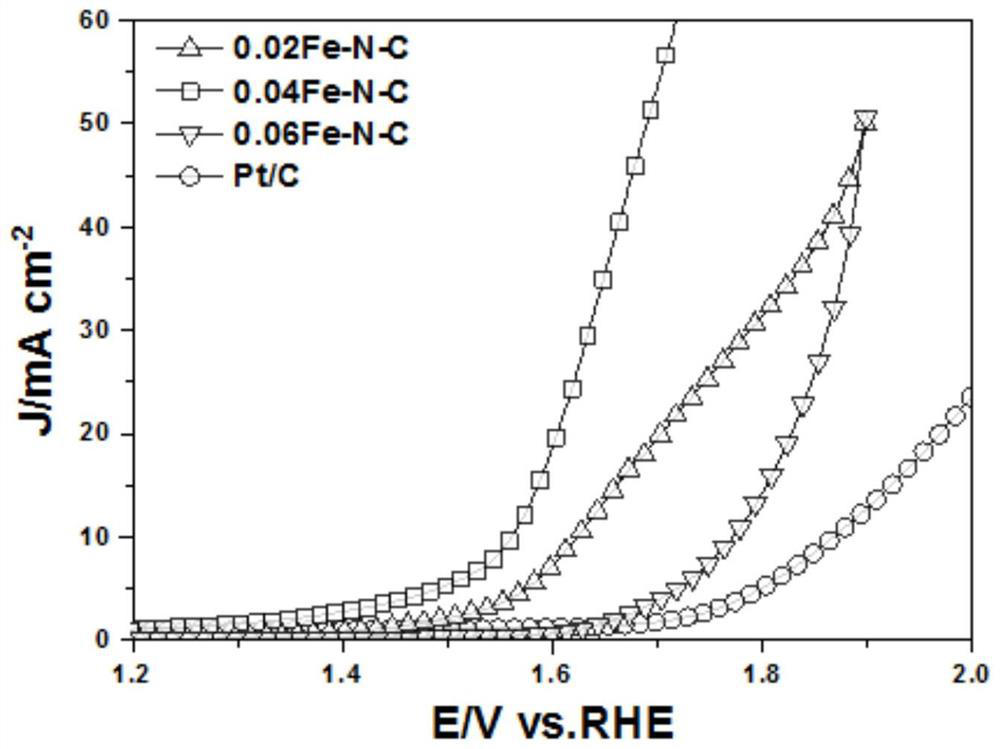

Image

Examples

Embodiment 1

[0039] A method for preparing a carbon-based catalyst, comprising the following steps:

[0040] Weigh 0.8755 g of zinc nitrate hexahydrate, 0.0174 g of nickel nitrate hexahydrate and 0.04 g of ferricyanide phthalocyanide into a 100 mL beaker, add 40 mL of anhydrous methanol, and perform ultrasonic stirring to obtain solution A;

[0041] Weigh 2.8 g of 1-vinylimidazole into a 50 mL round-bottomed flask, add 0.056 g of azobisisobutyronitrile, and stir and polymerize in a water bath at 65°C for 20 minutes under a nitrogen atmosphere to obtain solution B;

[0042] Slowly add solution B dropwise to solution A with continuous magnetic stirring, and after stirring at room temperature for 5 minutes, transfer the mixed solution to a 100mL reactor, and perform hydrothermal treatment at 90°C for 24 hours; then centrifuge and wash with absolute ethanol for 8 After that, place it in a vacuum oven at 60°C and dry for 12 hours to obtain the reaction product;

[0043] Place the prepared reac...

Embodiment 2

[0045] A method for preparing a carbon-based catalyst, comprising the following steps:

[0046] Weigh 0.3687 g of zinc carbonate, 0.0071 g of nickel carbonate and 0.02 g of ferrocyanide into a 100 mL beaker, add 40 mL of anhydrous methanol, and perform ultrasonic stirring to obtain solution A;

[0047]Weigh 2.8 g of 1-vinylimidazole into a 50 mL round bottom flask, add 0.056 g of azobisisobutyronitrile, and polymerize with stirring in a water bath at 55°C for 10 minutes under a nitrogen atmosphere to obtain solution B;

[0048] Slowly add solution B dropwise to solution A with continuous magnetic stirring, and after stirring at room temperature for 15 minutes, transfer the mixed solution to a 100mL reactor, and perform hydrothermal treatment at 70°C for 18 hours; then centrifuge and wash with absolute ethanol for 8 After that, place it in a vacuum oven at 60°C and dry it for 18 hours to obtain the reaction product;

[0049] Place the prepared reaction product in a high-temper...

Embodiment 3

[0051] A method for preparing a carbon-based catalyst, comprising the following steps:

[0052] Weigh 0.5408 g of zinc acetate, 0.0106 g of nickel carbonate and 0.06 g of ferrocyanide into a 100 mL beaker, add 40 mL of anhydrous methanol, and perform ultrasonic stirring to obtain solution A;

[0053] Weigh 2.8 g of 1-vinylimidazole into a 50 mL round bottom flask, add 0.056 g of azobisisobutyronitrile, and polymerize with stirring in a water bath at 70°C for 30 minutes under a nitrogen atmosphere to obtain solution B;

[0054] Slowly add solution B dropwise to solution A with continuous magnetic stirring, and after stirring at room temperature for 30 minutes, transfer the mixed solution to a 100mL reactor, and perform hydrothermal treatment at 110°C for 30 hours; then use absolute ethanol to centrifuge and wash for 8 After that, place it in a vacuum oven at 60°C and dry for 24 hours to obtain the reaction product;

[0055] Place the prepared reaction product in a high-tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com