Prefabricated glass fiber reinforced plastic corrugated sandwich sheet pile and assembling mode thereof

A technology of corrugated sheet piles and sandwich panels, applied in sheet pile walls, quay walls, sea area projects, etc., can solve problems such as long construction period, corrosion and deterioration of steel structures, and achieve avoidance of large-scale excavation and flexural performance Strong, strong stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

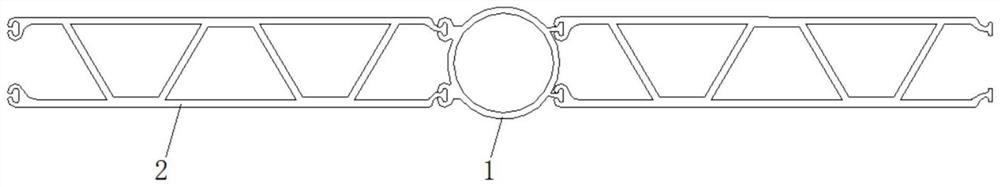

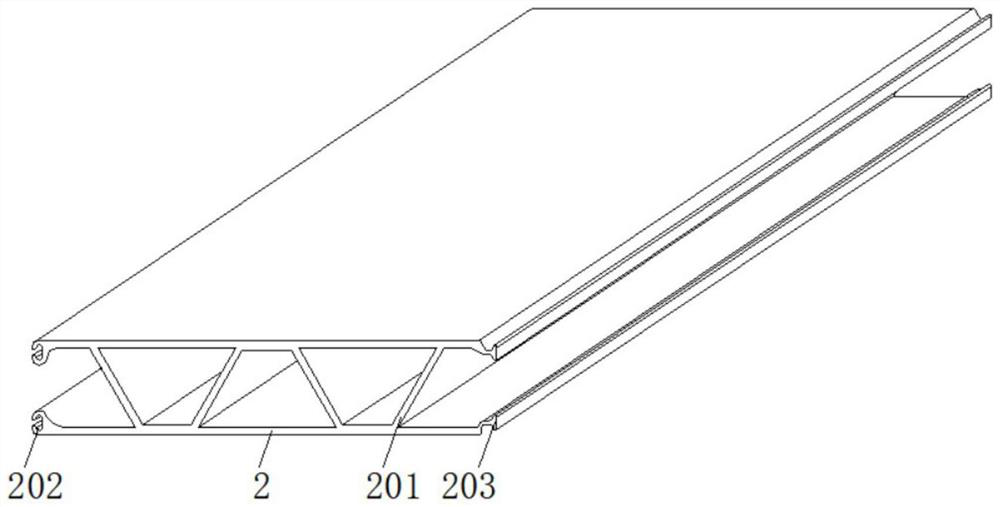

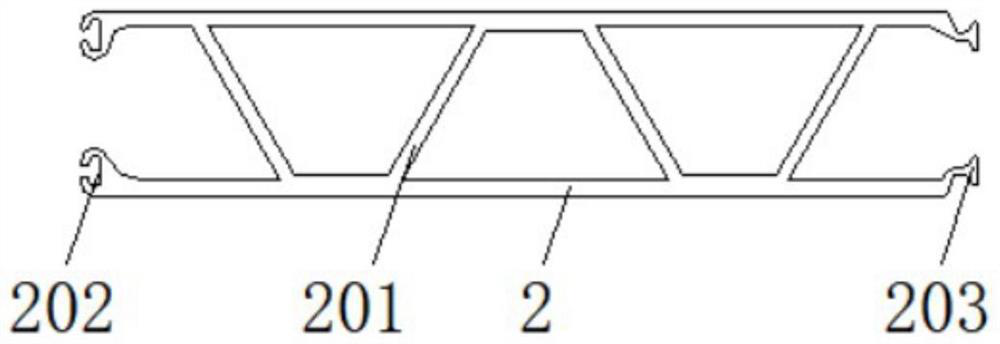

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a prefabricated FRP corrugated sandwich sheet pile and its assembly method include a connecting round pile 1 and hollow corrugated sheet piles 2 located on both sides of the connecting round pile 1. The hollow corrugated sheet pile 2 is integrally provided with a supporting frame 201 One end of the hollow corrugated sheet pile 2 is provided with two symmetrically distributed limit notches 202, the other end is integrally provided with a limit insert 203, and the connecting round pile 1 is provided with two limit inserts 203. There are two T-shaped fixing blocks 102 that match the limiting notch 202 on the connecting round pile 1, and the central axis of the fixing blocks 102 is parallel to the horizontal line.

[0030] An assembly method of prefabricated fiberglass corrugated sandwich sheet piles, comprising the following steps:

[0031] S1. Assemble the two hollow corrugated sheet piles 2 ...

Embodiment example 2

[0034] Such as figure 2 , image 3 , Figure 5 and Figure 6 As shown, a prefabricated FRP corrugated sandwich sheet pile and its assembly method include a connecting round pile 1 and hollow corrugated sheet piles 2 located on both sides of the connecting round pile 1. The hollow corrugated sheet pile 2 is integrally provided with a supporting frame 201 One end of the hollow corrugated sheet pile 2 is provided with two symmetrically distributed limit notches 202, the other end is integrally provided with a limit insert 203, and the connecting round pile 1 is provided with two limit inserts 203. The groove claw 101 of the connecting round pile 1 is also provided with two T-shaped fixing blocks 102 suitable for the limit notches 202, and the central axis of the fixing blocks 102 is 30° to the horizontal line.

[0035] An assembly method of prefabricated fiberglass corrugated sandwich sheet piles, comprising the following steps:

[0036] S1. Assemble the two hollow corrugate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com