Mechanical nano sealant and preparation method thereof

A sealant and nanotechnology, applied in the field of sealants, can solve the problems of poor UV resistance and water resistance, and achieve the effects of improving viscosity and flame retardancy, improving mechanical properties and thixotropic properties, and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

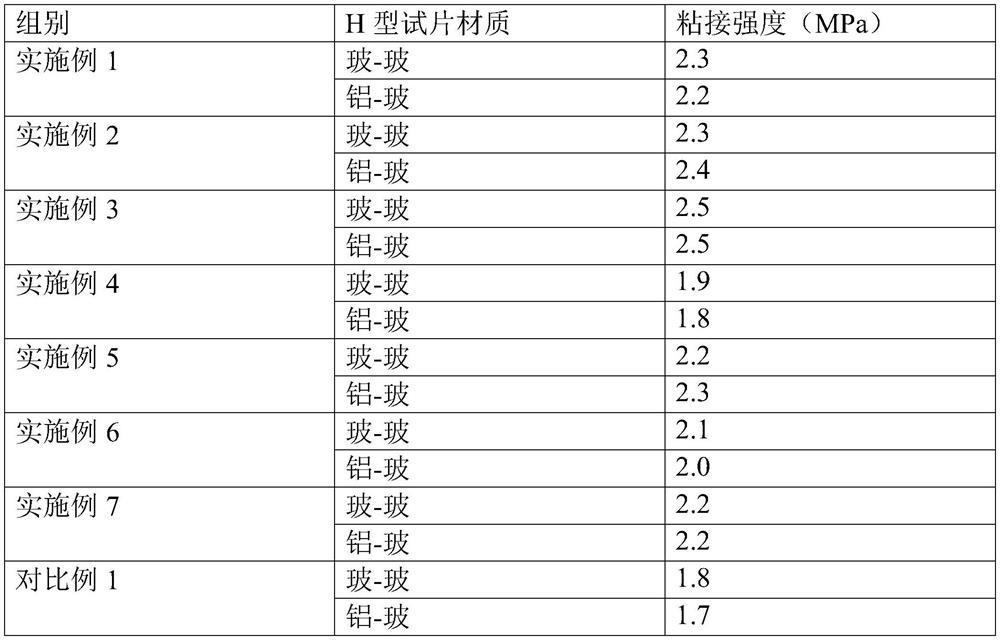

Examples

Embodiment 1

[0047] This embodiment provides a method for preparing a mechanical nano-sealant, which specifically includes the following steps:

[0048] S1. Preparation of the water phase: adding polyethylene glycol octyl phenyl ether to the calcium hydroxide saturated solution to obtain a water phase; wherein, the content of the polyethylene glycol octyl phenyl ether is 1 wt %;

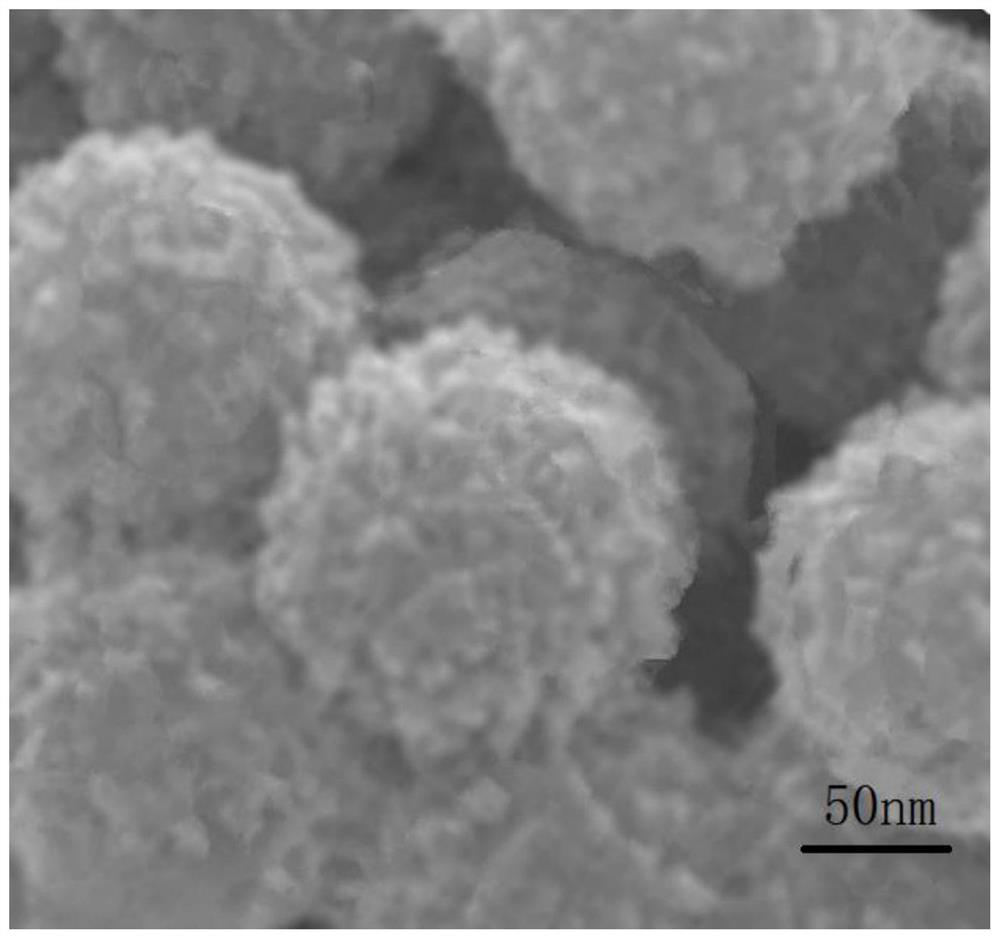

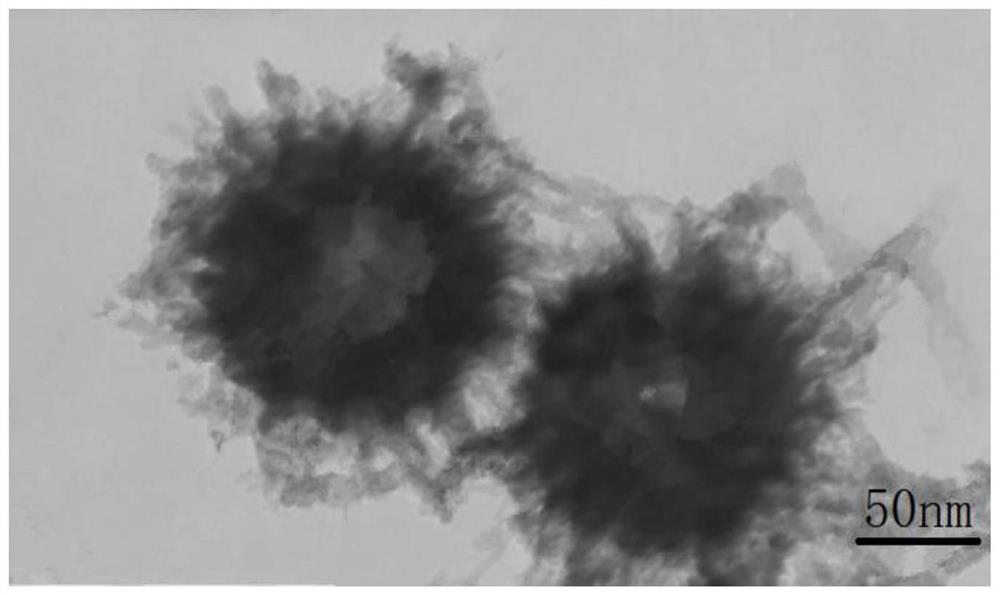

[0049] S2. Preparation of porous nano-calcium carbonate hollow spheres: add 50 parts by weight of the aqueous phase prepared in step S1 to 100 parts by weight of toluene containing 3wt% octenyl succinate starch, emulsify, and the emulsification speed is 11000r / min, emulsify The time is 5 minutes, carbon dioxide gas is passed into the obtained emulsion, the time of passing carbon dioxide is 10 minutes, the ventilation rate is 5L / min, repeat the emulsification and ventilation steps 3 times, centrifuge at 3000r / min for 15min, and dry at 70°C for 2h to obtain a porous Nano calcium carbonate hollow microspheres;

[0...

Embodiment 2

[0058] This embodiment provides a method for preparing a mechanical nano-sealant, which specifically includes the following steps:

[0059] S1. Preparation of the water phase: adding polyoxyethylene sorbitan fatty acid ester to the calcium hydroxide saturated solution to obtain a water phase; wherein, the content of the polyoxyethylene sorbitan fatty acid ester is 3 wt %;

[0060]S2. Preparation of porous nano-calcium carbonate hollow spheres: adding 50 parts by weight of the aqueous phase prepared in step S1 to 100 parts by weight of cyclohexane containing 6 wt% glyceryl monostearate, emulsifying, the emulsifying speed is 13000r / min, The emulsification time is 10 minutes, carbon dioxide gas is passed into the obtained emulsion, the time of passing carbon dioxide is 15 minutes, the ventilation rate is 10L / min, the emulsification and ventilation steps are repeated 7 times, centrifuged at 3000r / min for 15min, and dried at 70°C for 2h to obtain Porous nano calcium carbonate hollo...

Embodiment 3

[0069] This embodiment provides a method for preparing a mechanical nano-sealant, which specifically includes the following steps:

[0070] S1. Preparation of the water phase: adding polyoxyethylene sorbitan fatty acid ester to the calcium hydroxide saturated solution to obtain a water phase; wherein, the content of the polyoxyethylene sorbitan fatty acid ester is 2 wt %;

[0071] S2. Preparation of porous nano-calcium carbonate hollow spheres: add 50 parts by weight of the aqueous phase prepared in step S1 to 100 parts by weight of petroleum ether containing 4.5wt% Span-80, emulsify, the emulsification speed is 12000r / min, and the emulsification time For 7 minutes, carbon dioxide gas was passed into the obtained emulsion. The time of passing carbon dioxide was 12 minutes, and the ventilation rate was 7L / min. Calcium carbonate hollow microspheres;

[0072] S3. Preparation of catalyst solution: Cobalt chloride is dissolved in the Tris-HCl buffer solution with a pH value of 8.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com