OCA (optical clear adhesive), full-lamination OCA touch screen and preparation method of full-lamination OCA touch screen

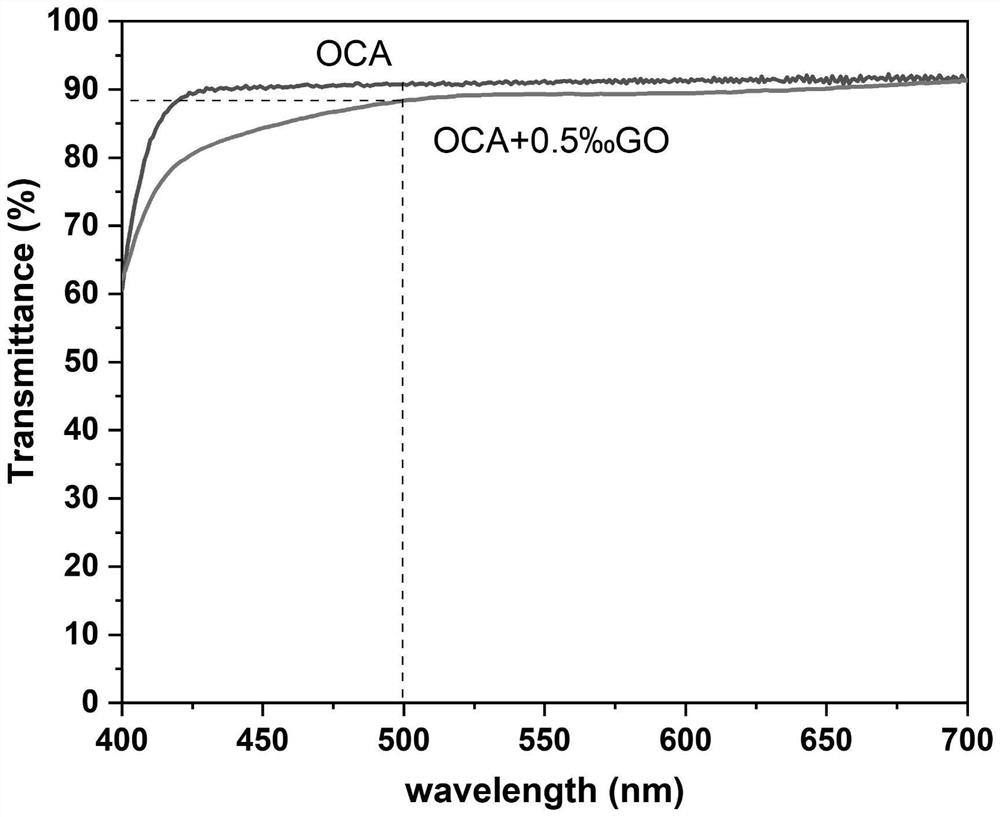

An optically transparent adhesive, touch screen technology, applied in the direction of adhesives, polyether adhesives, adhesive types, etc., can solve the problem of uneven force on both sides of fully laminated polarizers, blue light leakage from electronic screens, and many times of lamination and other problems, to achieve the effect of reducing the blue light transmittance, reducing the number of laminations, and improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

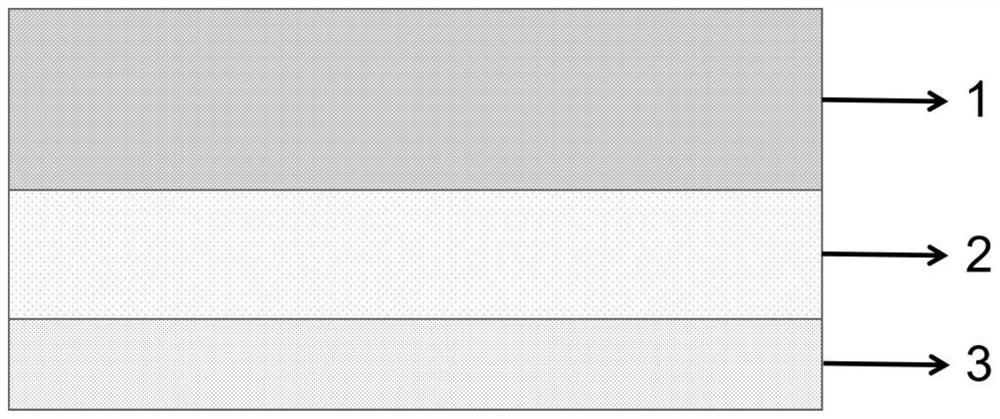

[0032] The invention provides a method for preparing a full-fit OCA touch screen, comprising the following steps:

[0033] Graphene oxide, prepolymer, tackifying resin, photoinitiator and reactive diluent are mixed and coated on the lower surface of the touch screen, and the OCA optically transparent adhesive layer is obtained after UV light curing;

[0034] A fully bonded OCA touch screen is obtained by attaching a release film to the lower surface of the OCA optically transparent layer.

[0035] In the present invention, the thickness of the OCA optically transparent adhesive layer is 50-250 μm, preferably 80-220 μm, more preferably 100-200 μm.

[0036] In the present invention, the UV light curing includes: using a light intensity of 50-200mW / cm 2 1. One or two kinds of mixed UV light curing with wavelengths of 254nm and 365nm for 20-180s; preferably, the light intensity is 100-150mW / cm 2 1. One or two kinds of mixed UV light curing with wavelengths of 254nm and 365nm for...

Embodiment 1

[0039] Preparation of OCA optically transparent glue:

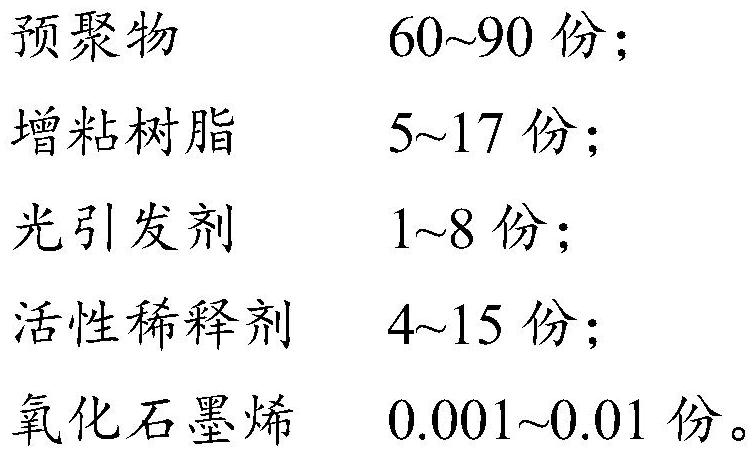

[0040] In parts by mass, mix 85 parts of polyurethane acrylic resin, 6.5 parts of terpene resin, and 6.2 parts of hexanediol diacrylate, then add 2.3 parts of benzophenone and stir evenly, and finally mix with 0.005 parts of graphene oxide Uniform, after vacuum defoaming treatment, liquid OCA optical glue is obtained.

[0041] Preparation of full-fit OCA touch screen:

[0042]Evenly coat the liquid OCA optically transparent adhesive on the lower surface of the touch screen, and then cure it with a UV lamp with a wavelength of 365nm for 50s to obtain an OCA optically transparent adhesive layer attached to the lower surface of the touch screen. The thickness of the adhesive layer after UV curing is 120 μm. The size of the adhesive layer is the same as the size of the lower surface of the touch screen. A release film of the same size is attached to the lower surface of the OCA optically transparent adhesive layer to protec...

Embodiment 2

[0044] Preparation of OCA optically transparent glue:

[0045] In parts by mass, mix 90 parts of polyester acrylate, 5 parts of rosin, and 10 parts of neopentyl glycol diacrylate, then add 5 parts of benzoin dimethyl ether and stir evenly, and finally mix with 0.01 part of graphene oxide Uniform, after vacuum defoaming treatment, liquid OCA optical glue is obtained.

[0046] Preparation of full-fit OCA touch screen:

[0047] Evenly coat the liquid OCA optically transparent adhesive on the lower surface of the touch screen, and then cure it with UV lamps with wavelengths of 254nm and 365nm for 60s to obtain an OCA optically transparent adhesive layer attached to the lower surface of the touch screen. The thickness of the adhesive layer after UV curing is 150μm, the size of the adhesive layer is the same as the size of the lower surface of the touch screen. A release film of the same size is attached to the lower surface of the OCA optically transparent adhesive layer to prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com