Olefin hydration reaction device and olefin hydration method

A technology of olefin hydration and reaction equipment, which is applied in the direction of chemical methods, feeding devices, chemical instruments and methods for liquid-liquid reactions, etc., and can solve the problems of slow hydration reaction rate, large water ratio, and difficulty in mixing uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

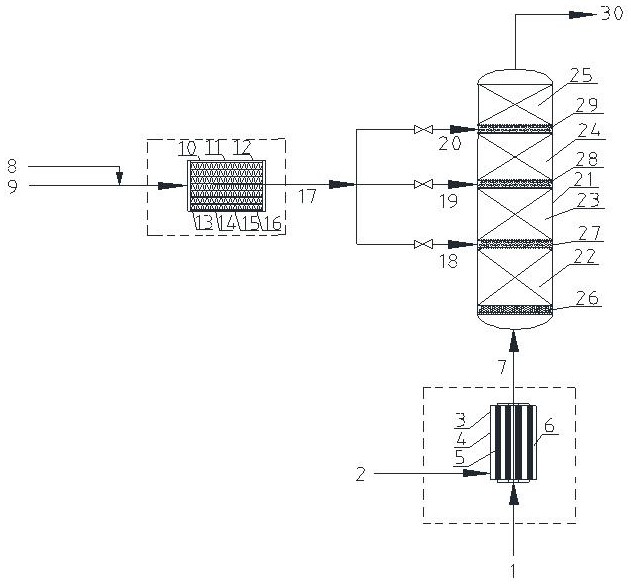

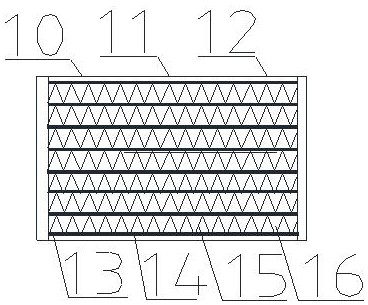

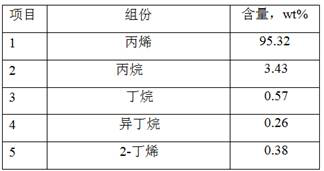

[0051]Propylene in Table 1 is used as raw material, and isopropanol is prepared by hydration reaction of propylene with water under the action of a catalyst. The water olefin mass ratio is introduced into the channel mixing device I with a ratio of 12:1 to form a mixed material I, which enters the olefin hydration reactor as the main reaction material and reacts in the catalyst bed; the water olefin mass ratio is 1:7.5 The mixed material II is formed through the microchannel mixing device II, which is introduced into the catalyst bed as an enhanced mass transfer material to strengthen the olefin hydration reaction process, and the reaction effluent leaves the reactor and enters the next separation unit.

[0052] The reactor adopts the reactor of the present invention, which enters from the bottom and exits from the top. Three catalyst beds are arranged in the reactor, and a stream of enhanced mass transfer is introduced between the first / second catalyst bed and between the seco...

Embodiment 2

[0055] In this embodiment, the operating conditions of the reaction raw materials, reactor structure, reaction process, microchannel mixing device I, and microchannel mixing device II are the same as in Example 1. Different from Example 1, this example adopts milder reaction conditions. The reaction conditions, residence time and raw material conversion are shown in Table 4.

Embodiment 3

[0057] Using n-butene in Table 2 as raw material, hydration reaction of n-butene with water under the action of catalyst to prepare sec-butanol. The water olefin mass ratio is introduced into the channel mixing device I with a ratio of 3:1 to form a mixed material I, which enters the olefin hydration reactor as the main reaction material and reacts in the catalyst bed; the water olefin mass ratio is 1:2 The mixed material II is formed through the microchannel mixing device II, which is introduced into the catalyst bed as an enhanced mass transfer material to strengthen the olefin hydration reaction process, and the reaction effluent leaves the reactor and enters the next separation unit.

[0058] The reactor adopts the reactor of the present invention, the bottom enters and the top exits, and four catalyst beds are arranged in the reactor, between the first / second catalyst bed, between the second / third catalyst bed, between the third / fourth catalyst bed The enhanced mass trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com