Steam crosslinking room for power cable crosslinking

A technology of steam cross-linking and power cable, applied in the field of steam cross-linking room, can solve the problems of difficult steam pressure regulation, fast steam heat dissipation, resource consumption, etc., and achieve the effects of improving uniformity, improving stability and avoiding contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

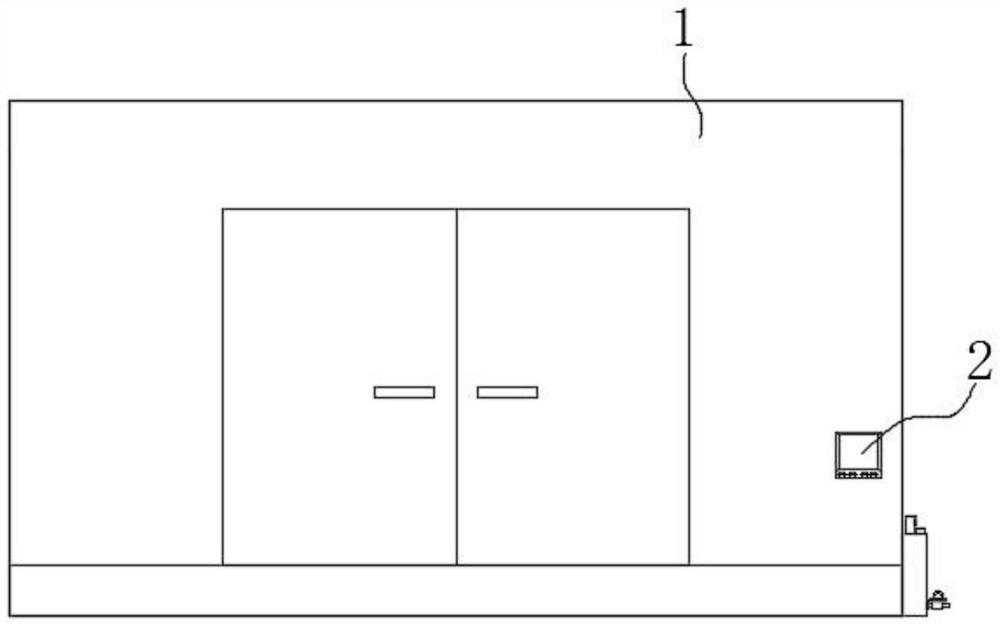

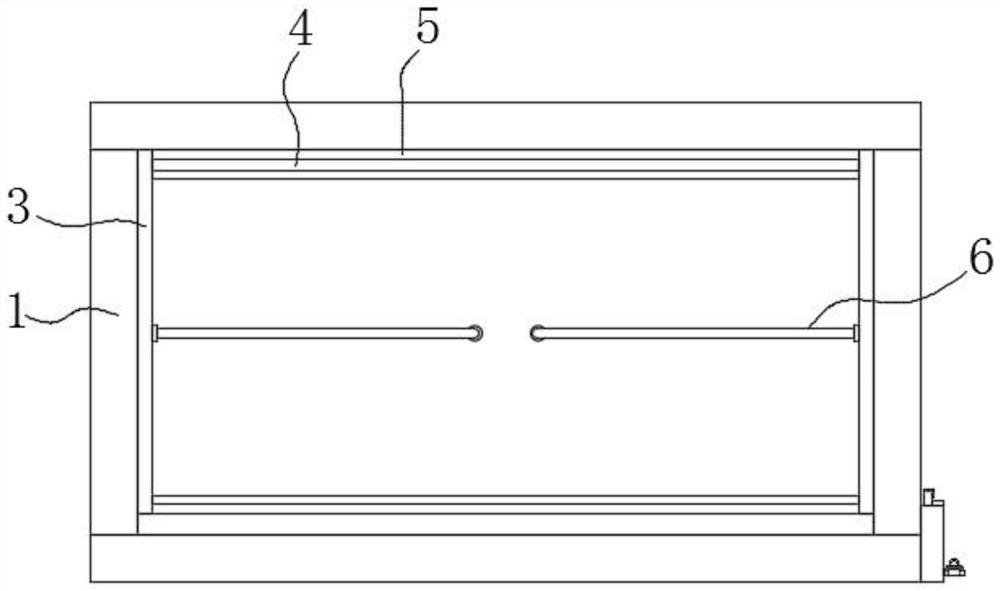

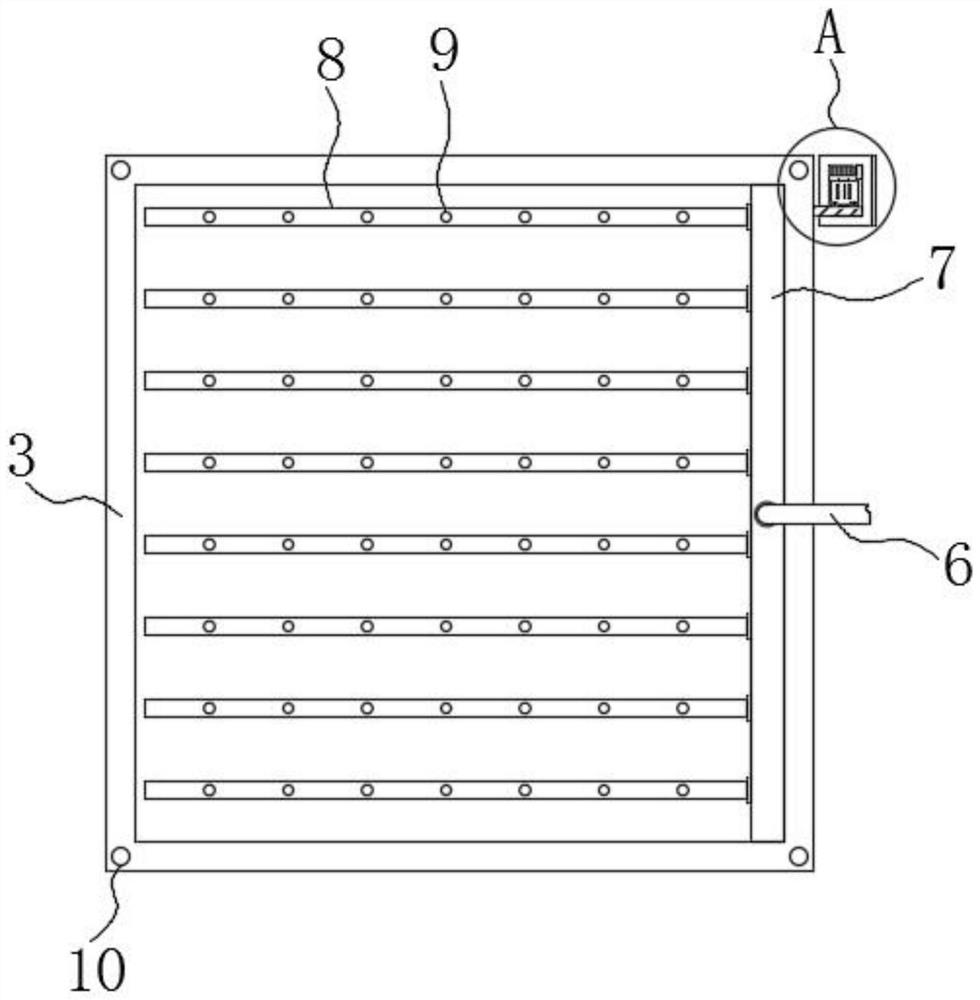

[0039] Such as Figure 1 to Figure 4As shown, the steam cross-linking room for power cable cross-linking in this embodiment, a steam cross-linking room for power cable cross-linking, includes a room body 1, a controller 2 is installed on the front surface of the room body 1, and the interior of the room body 1 Both sides are provided with a support frame 3, and a fixed pipe 7 is fixed on the inner side of the support frame 3, and several air outlet pipes 8 are connected to one side of the fixed pipe 7, and an air guide hose 6 is connected to one side of the fixed pipe 7 , the air outlet pipe 8 is provided with a number of spray holes 9, the steam is passed into the air guide hose 6, the steam will enter the air outlet pipe 8 through the fixed pipe 7, and then spray out from the spray holes 9, so that the steam enters the room evenly body 1, in order to ensure that the cable cross-linking operation can be completed stably, the inside of the support frame 3 is located at the fou...

Embodiment 2

[0044] The structure of the steam cross-linking room for power cable cross-linking in this embodiment is basically the same as that of the steam cross-linking room for power cable cross-linking in Embodiment 1, the difference is that a water storage frame 15 is fixed at the inner bottom of the room body 1 A support block 17 is fixed above the inside of the water storage frame 15, a grid plate 16 is placed on the top of the support block 17, the top of the grid plate 16 is flush with the top of the water storage frame 15, and the outside of the house body 1 is provided with Water storage cylinder 21, connecting pipe 18 is connected between water storage cylinder 21 and water storage frame 15, heat will be absorbed during the cable cross-linking process, and then steam will be converted into water droplets, when the water droplets fall, they will directly pass through the grid plate 16 Enter the inside of the water storage frame 15, and then the water droplets will enter the wate...

Embodiment 3

[0050] The structure of the steam cross-linking room for power cable cross-linking in this embodiment is basically the same as the structure of the steam cross-linking room for power cable cross-linking in Example 1, the difference is that the room body 1 is spliced by six boards through the connecting mechanism A door is installed on one of the boards so that the staff can go in and out; Located inside the rectangular frame-like structure, the joints of the four horizontal plates 30 and the joints of the horizontal plates 30 and the support plate 27 are all welded and fixed; On one side of the board 30, several fixed posts 25 on one of the boards are all inserted into the inside of the adjacent board, and the outside of the fixed post 25 is threadedly connected with a fixed bolt 24, because the room body 1 is connected by six boards and Mechanisms are spliced together, therefore, the disassembly and assembly operation of the room body 1 can be quickly completed, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com