Method for improving efficiency of treating pulp fibers by cellulase

A technology of cellulase and cellulose, applied in the field of papermaking, can solve the problems of low efficiency of biological enzyme action and decreased paper sheet strength, and achieve the effect of high pulp processing efficiency and improved dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a kind of preparation method of immobilized cellulase, comprises the following steps:

[0018] The cellulose nanofiber liquid and the cellulase enzyme liquid are mixed to obtain immobilized cellulase.

[0019] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known in the art.

[0020] In the present invention, the length of the cellulose nanofibers in the cellulose nanofiber liquid is preferably 1-100 nm, more preferably 10-90 nm, even more preferably 20-80 nm. The cellulose nanofibers are preferably cellulose nanofibers prepared from bleached kraft pulp of softwood or bleached kraft pulp of hardwood.

[0021] In the present invention, the mass concentration of the cellulose nanofiber liquid is preferably 0.1-1.0%, more preferably 0.2-0.8%, and even more preferably 0.4-0.6%. The cellulose nanofiber liquid is preferably prepared by the following method: treating softwood kraft p...

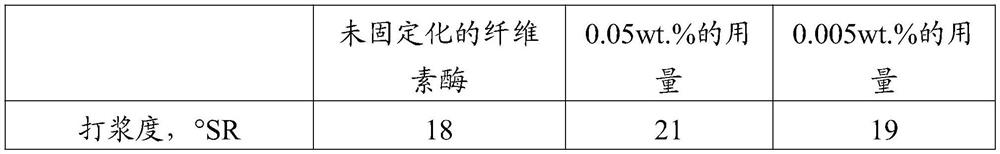

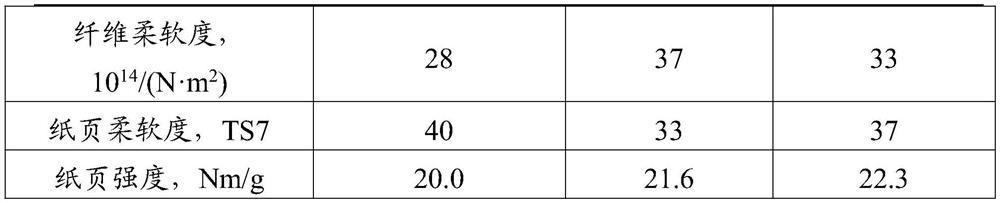

Embodiment 1

[0033] Step 1: Add 5.0 g of cellulase enzyme liquid with a mass concentration of 0.1% to 2.0 g of cellulose nanofiber liquid with a mass concentration of 0.1% and a fiber length of 10 nm, and stir;

[0034] Step 2: Insulate in a water bath at a temperature of 30°C for 30 minutes;

[0035] Step 3: cooling the cellulase enzyme solution in step 2 to room temperature to form stable immobilized cellulase;

[0036] Step 4: Add the immobilized cellulase in step 3 to the softwood bleached kraft pulp slurry with a concentration of 0.1 wt.% in an amount of 0.005 wt.%, and treat it at room temperature for 5 minutes;

[0037] Step 5: Determination of the beating degree and softness performance of the pulp fiber, compared with the unimmobilized cellulase treatment, the beating degree of the pulp increased by 1 ° SR, and the fiber softness increased by 5 × 10 14 / (N·m 2 ), the weight of the processed slurry is 20g / m 2 paper, the softness of the paper has increased by 2 units, and the str...

Embodiment 2

[0041] Step 1: Add 5.0 g of cellulase enzyme liquid with a mass concentration of 0.5% to 2.0 g of cellulose nanofiber liquid with a mass concentration of 0.1% and a fiber length of 100 nm, and stir;

[0042] Step 2: keep warm in a water bath at a temperature of 30°C for 60 minutes;

[0043] Step 3: cooling the cellulase enzyme solution in step 2 to room temperature to form stable immobilized cellulase;

[0044] Step 4: Add the immobilized cellulase in step 3 to the hardwood bleached kraft pulp slurry with a concentration of 1.0 wt.% in an amount of 0.05 wt.%, and treat for 30 minutes at room temperature;

[0045] Step 5: Determining the beating degree and softness performance of the pulp fiber, compared with the unimmobilized cellulase treatment, the beating degree of the pulp increased by 3°SR, and the fiber softness increased by 10×10 14 / (N·m 2 ), the weight of the processed slurry is 30g / m 2 paper, the paper softness increased by 7 units, and the paper strength increase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com