Continuous hydrothermal carbonization method

A technology for hydrothermal carbonization and hydrothermal carbonization, which is applied in the field of agricultural and forestry waste utilization, can solve problems such as difficulty in application, and achieve the effects of high charging efficiency, low alkali metal content and high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

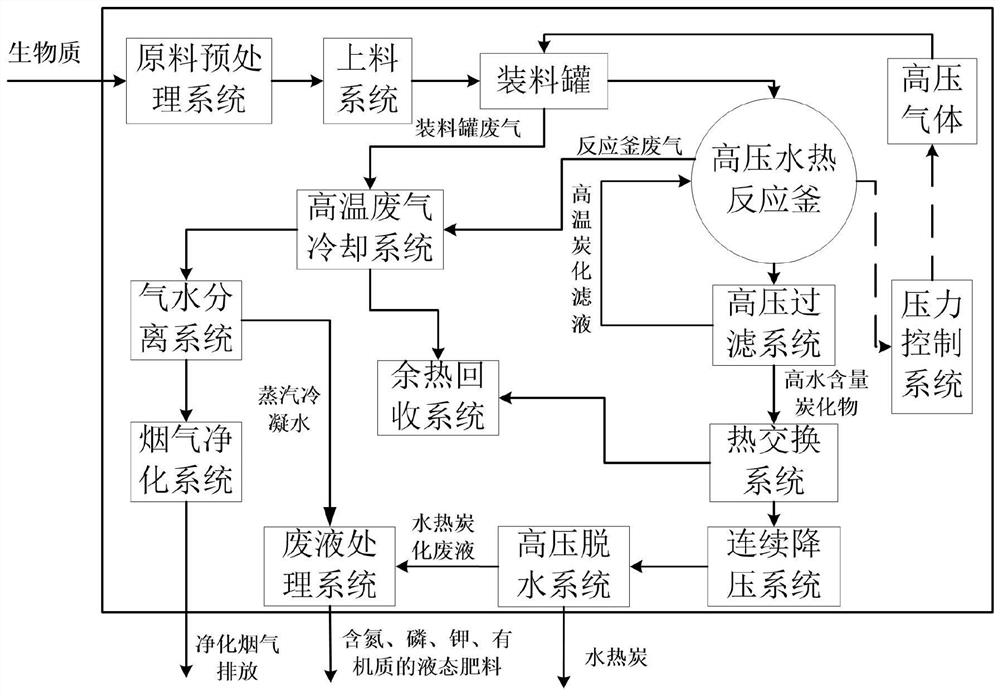

[0029]This example provides a continuous hydrothermal carbonization method using biomass solid particles as raw material. Taking soybean straw as an example, the process is as follows figure 1 shown, including the following steps:

[0030] (1) Use the raw material pretreatment system to pretreat the raw materials. Specifically, sieve the soybean straw to remove mud, gravel, iron flakes, etc., you can use a vibrating screen or other screening equipment, which needs to be removed during the sieving process. The entrainment of waste rubber and rags can be realized by using existing equipment or manpower, and then, the soybean straw is cut into pieces by a shearing machine, and the length of the straw is controlled to be less than 10cm. Conveying to the top of the charging tank;

[0031] (2) Close the feeding port of the charging tank, open the pressure relief valve, discharge the high-temperature exhaust gas in the charging tank to the high-temperature exhaust gas cooling system...

Embodiment 2

[0038] This embodiment provides a continuous hydrothermal carbonization method using biomass solid particles as raw materials. Taking waste wood as an example, the process is as follows figure 1 shown, including the following steps:

[0039] (1) Use a crusher to crush large pieces of waste wood, and control the particle size of the waste wood to be less than 10cm. The crushed waste wood is weighed and transported to the top of the charging tank by a spiral conveying pipeline;

[0040] (2) Close the feeding port of the charging tank, open the pressure relief valve, discharge the high-temperature exhaust gas in the charging tank to the high-temperature exhaust gas cooling system, close the pressure relief valve when the internal pressure of the charging tank is equal to the atmospheric pressure, and open the upper At the feed port, put the waste wood into the charging tank, and the loading capacity is 1.8t each time. After the filling is completed, close the upper charging port...

Embodiment 3

[0046] This embodiment provides a continuous hydrothermal carbonization method using biomass solid particles as a raw material, taking garden trimmings as an example, the flow process is as follows figure 1 shown, including the following steps:

[0047] (1) Use the raw material pretreatment system to pretreat the raw materials. Specifically, screen the garden prunings to remove mud, gravel, and iron pieces. Vibrating screens or other screening equipment can be used, which need to be removed during the screening process. The entrained waste rubber and rags can be realized by using existing equipment or manpower, and then, the garden prunings are shredded by a shearing machine, and the length of the straw is controlled to be less than 10 cm. The conveying pipeline is conveyed to the top of the charging tank;

[0048] (2) Close the feeding port of the charging tank, open the pressure relief valve, discharge the high-temperature exhaust gas in the charging tank to the high-temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com