Scrap preheater, arc melting device and preheating method

A technology of preheating device and scrap steel, applied in the field of metallurgy, can solve the problems of equipment water leakage, deformation and cracking of finger-like mechanisms, and achieve the effect of continuous addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

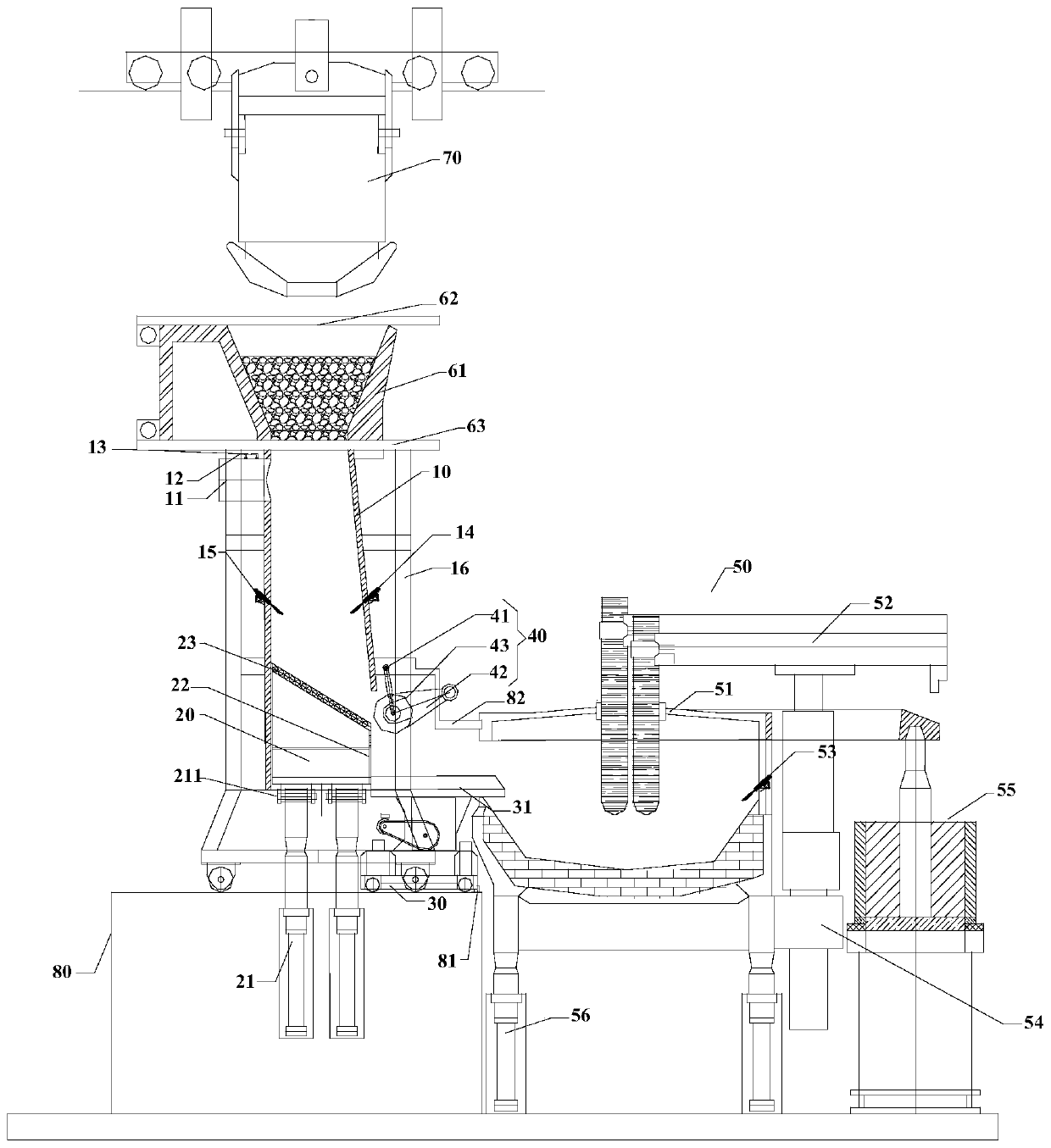

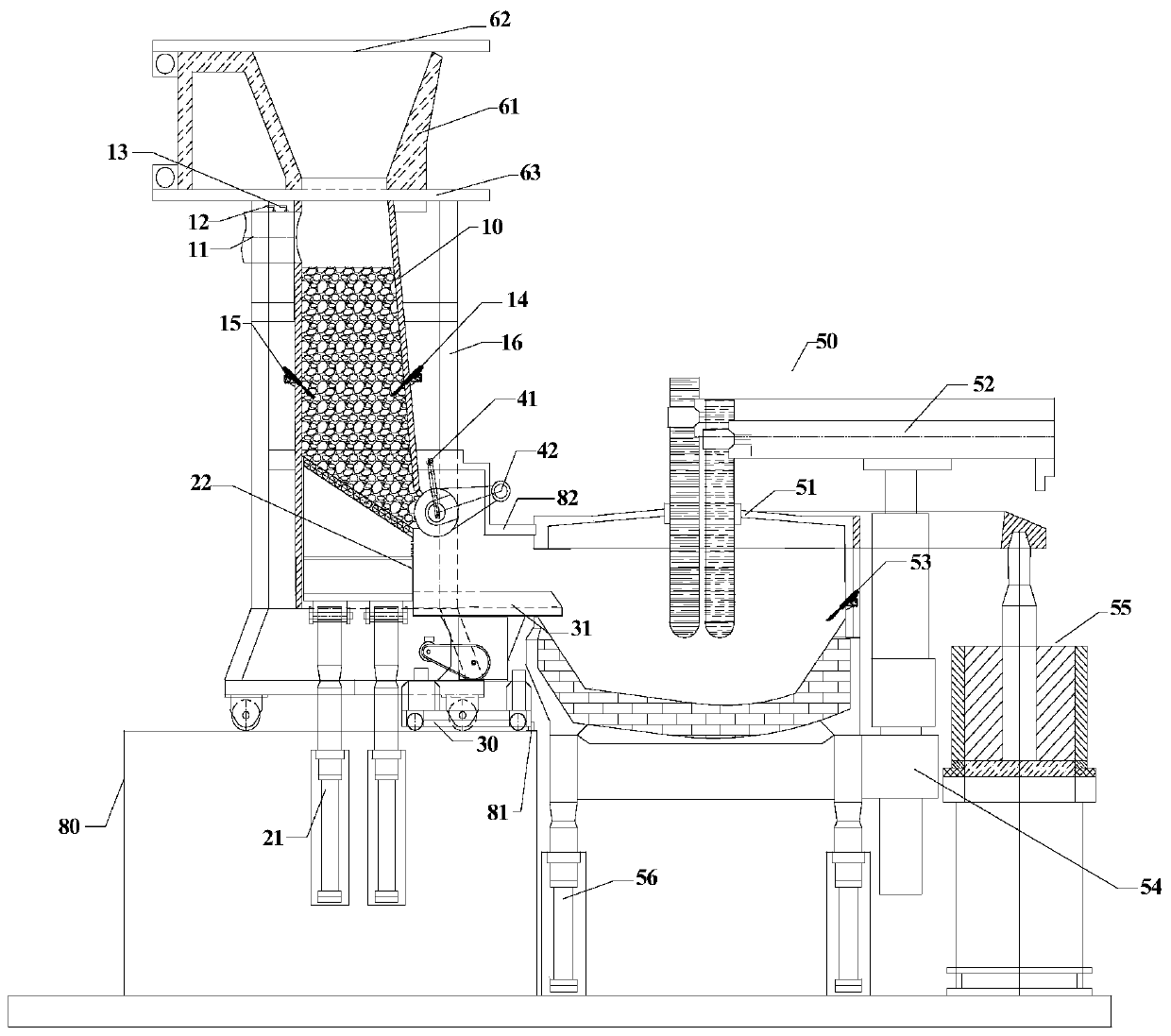

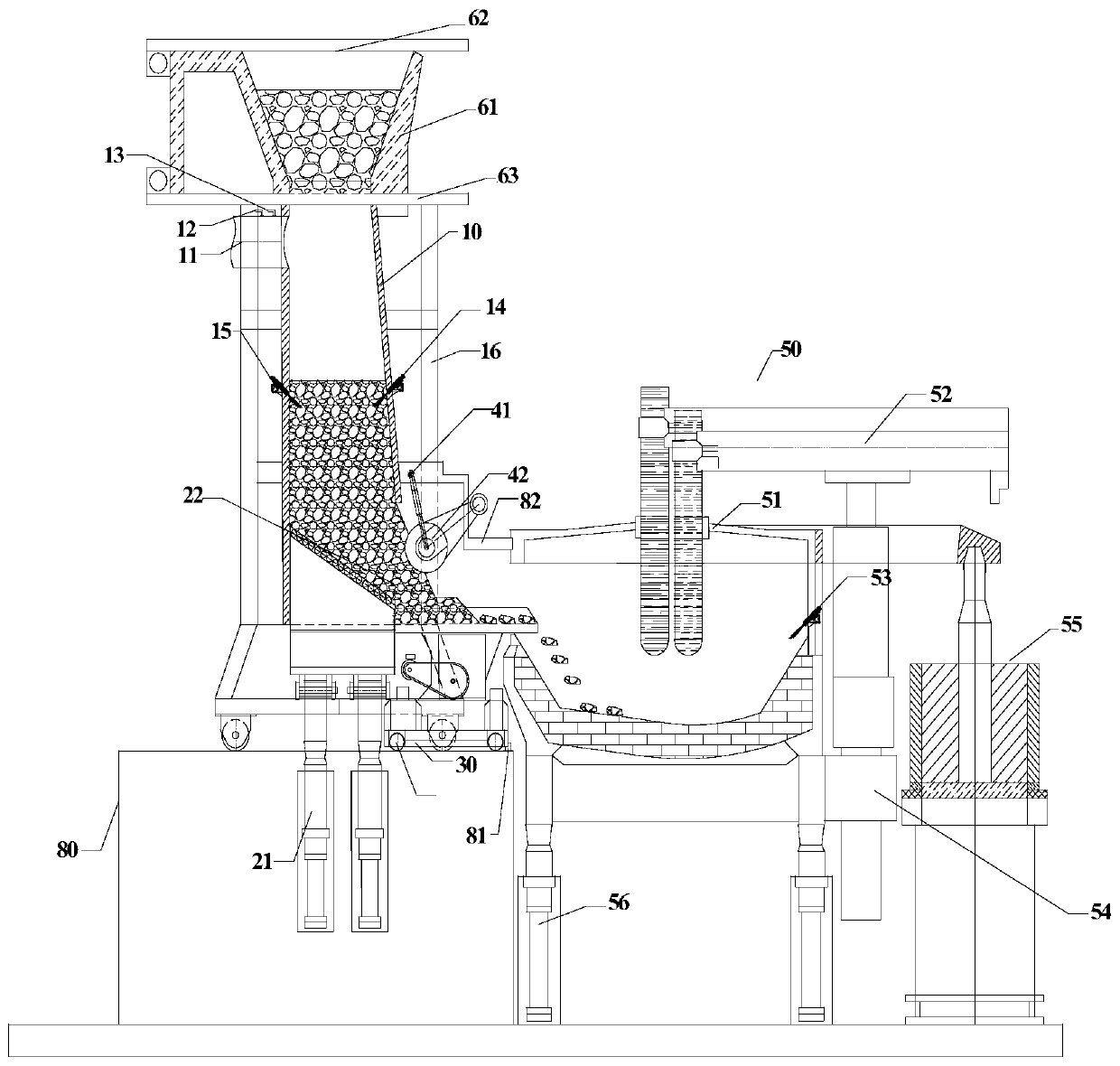

[0039] Such as Figure 1 to Figure 7 As shown, the embodiment of the present invention provides a scrap steel preheating device, including a shaft 10 , an unloader 20 , a transport trolley 30 and a guide roller 40 . The upper end of the shaft 10 is a material inlet, and the side wall of the lower end of the shaft 10 is provided with a material outlet. The unloader 20 is arranged in the shaft 10 and can move vertically relative to the shaft 10 . The unloader 20 has an upper surface inclined towards the discharge opening. The material transport trolley 30 can vibrate material transport, the inlet end of the material transport trolley 30 is sealed and connected with the discharge port, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com