Preparation method of monomeric diamine compound of polyimide

A technology of diamine compound and polyimide, applied in the field of preparation of monomeric diamine compound, can solve the problems of low yield, complicated preparation process, etc., and achieves safe and simple reaction, high solubility, and avoids troublesome post-processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

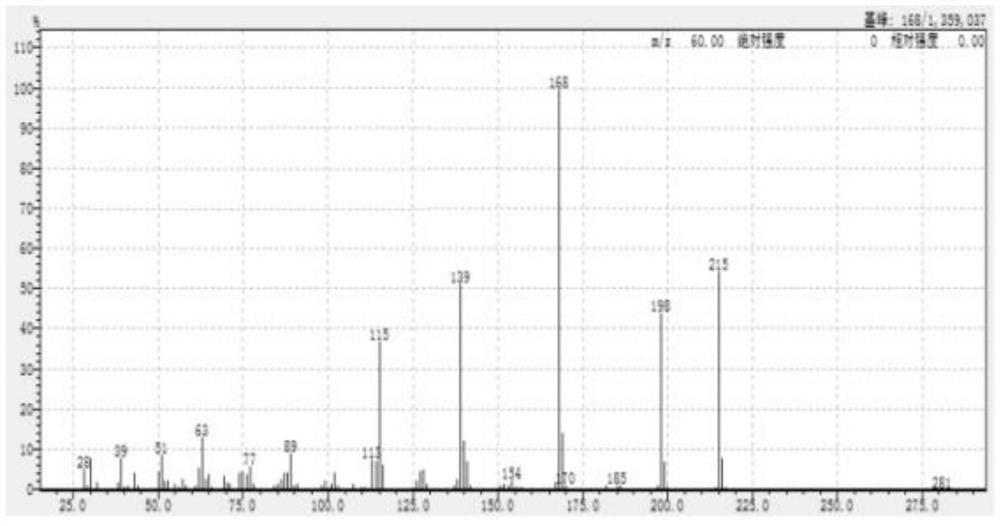

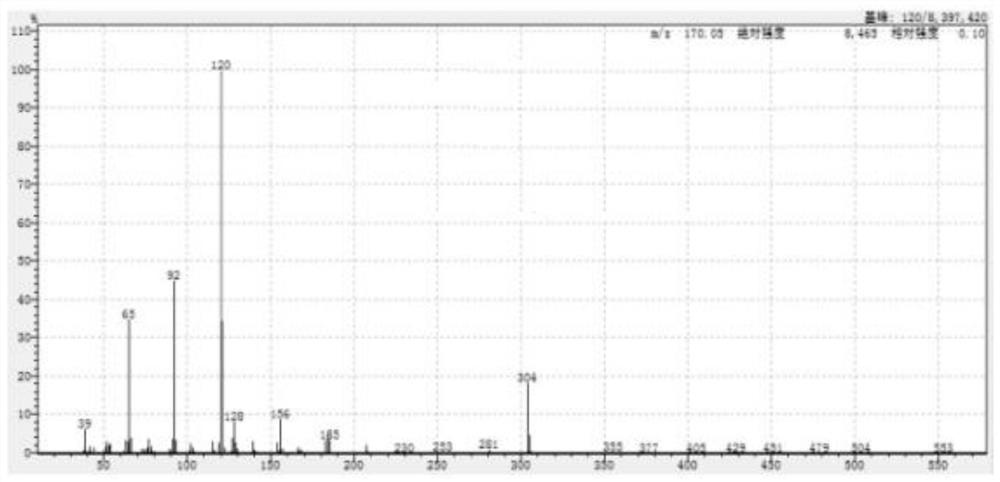

Image

Examples

preparation example Construction

[0030] More specifically, the preparation method of the monomeric diamine compound of the polyimide disclosed by the present invention comprises the steps of:

[0031] Step 1: Add o-chloro-p-nitrophenol and the first inorganic base into the mixed system of dioxane and water, then add a methylating reagent to react, extract and separate to obtain o-chloro-p-nitroanisole solution ;

[0032] Further, the molar ratio of o-chloro-p-nitrophenol and the first inorganic base is 1:1-1.5, preferably 1:1.2; the molar ratio of o-chloro-p-nitrophenol and methylating agent is 1:1-1.5 , preferably 1:1.3. Dioxane and water are used as solvents, which can be determined according to the dosage and solubility of o-chloro-p-nitrophenol and the first inorganic base, and can be set in excess.

[0033] Further, in step 1, add o-chloro-p-nitrophenol and the first inorganic base to the mixed system of dioxane and water and then raise the temperature to 40-50°C, then add a methylating reagent and hea...

Embodiment 1

[0050] This embodiment discloses a method for preparing a polyimide monomer diamine compound, which specifically includes the following steps:

[0051] Step 1: Add 174ml of water, 348ml of dioxane, 173.6g of o-chloro-p-nitrophenol, and 165.6g of potassium carbonate to the reaction device in sequence. Carry out heat preservation reaction at 90°C. After the reaction, cool down the system to 40°C. Add 348ml of water and 695ml of toluene to the system for extraction and washing. After liquid separation, the o-chloro-p-nitroanisole solution is obtained. , the yield is 100%;

[0052] Step 2: Take another reaction device and add the p-o-chloro-p-nitrotoluene ether solution prepared in step 1, potassium carbonate 165.5g, phenylboronic acid 134.2g, tetrabutylammonium bromide 96.7g, add tetrakis (triphenylphosphine ) Palladium (0) 1.16g, purified water 348ml, start stirring, heating, the temperature of the system is raised to 80°C for reaction, and the reaction is kept for 5 hours. Aft...

Embodiment 2

[0056] This embodiment discloses a method for preparing a monomeric diamine compound of polyimide, comprising steps:

[0057] Step 1: Add 174ml of water, 348ml of dioxane, 173.6g of o-chloro-p-nitrophenol, and 40.0g of sodium hydroxide to a reaction device in sequence, adjust the temperature of the system to 40°C, and then add 126.1g of dimethyl sulfate , the system was heated up to 80°C for heat preservation reaction. After the reaction, the system was cooled to 40°C, and 348ml of water and 695ml of toluene were added to the system for extraction and water washing. After liquid separation, o-chloro-p-nitroanisole solution was obtained, which was detected by HPLC The content is 97.8%, and the yield is 100%;

[0058] Step 2: get another reaction device to add successively the p-o-chloro-p-nitrotoluene ether solution that step 1 makes, potassium carbonate 165.5g, phenylboronic acid 134.2g, tetrabutylammonium bromide 96.7g, add palladium catalyst two ( Triphenylphosphine)palladi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com