Concrete curing agent, curing coating and preparation method thereof

A concrete curing agent and concrete technology, applied in the field of concrete, can solve problems such as easy cracking, low hardness, and insufficient strength, and achieve the effects of improving water retention, surface strength, and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

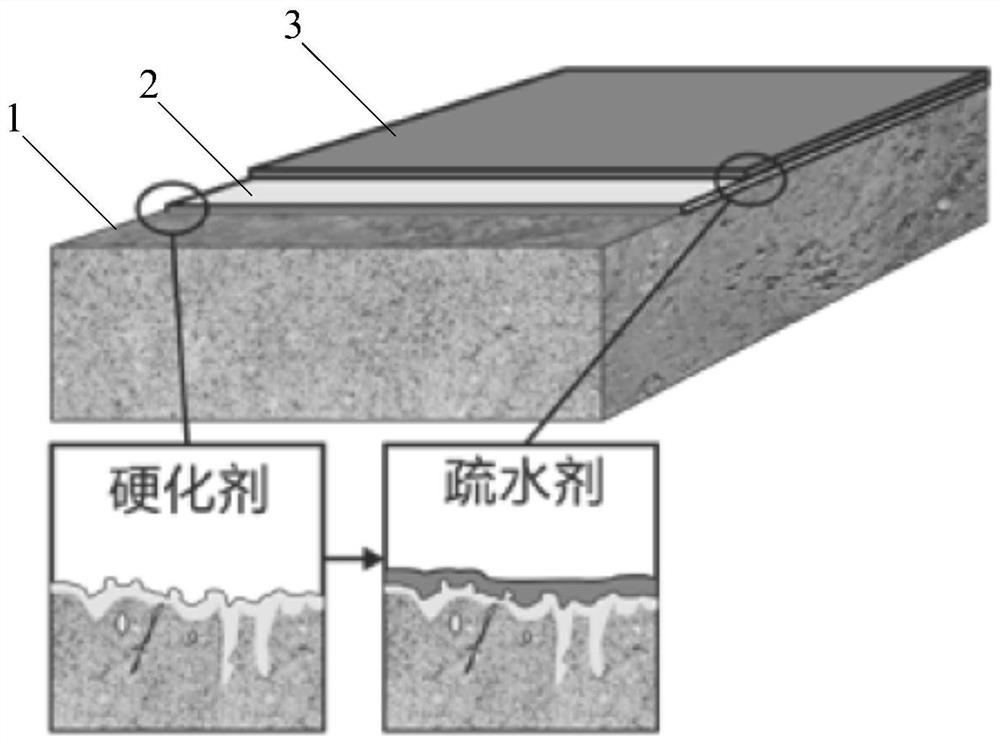

[0078]The present invention also proposes a preparation method of concrete curing coating, the preparation method adopts the above-mentioned concrete curing agent, and the preparation method comprises the following steps:

[0079] Step 1, weighing fluorosilicate and water according to the proportion, stirring and mixing evenly to obtain the hardener;

[0080] Step 2, weighing the alkali catalyst and water according to the proportion, stirring and mixing uniformly to obtain a catalytic liquid, weighing the silane coupling agent, hydrogen-containing silicone oil, crosslinking agent and silica sol according to the proportion, stirring and mixing uniformly to obtain a precursor; The precursor and the catalytic solution are placed in a nitrogen-protected reaction vessel, and stirred and mixed evenly at a temperature of -20-30°C (such as -20°C, 10°C, 0°C, 10°C, 20°C or 30°C) to obtain hydrophobic agent;

[0081] Step 3: apply the hardener on the surface of the concrete, and within ...

Embodiment 1

[0088] The concrete curing agent provided in this embodiment is composed of a hardener and a hydrophobic agent, wherein, in parts by weight, the raw material of the hardener includes 5 parts of fluorosilicate (4 parts of magnesium fluorosilicate, 1 part of ammonium fluorosilicate) and 100 parts of water, the raw materials of hydrophobic agent include: 5 parts of alkali catalyst (3 parts of potassium hydroxide, 2 parts of calcium hydroxide), 5 parts of silane coupling agent (2-(3,4-epoxycyclohexane base) ethyl triethoxysilane coupling agent 1 part, N-(β-aminoethyl)-γ-aminopropyl trimethyl (ethyl) oxysilane 4 parts), hydrogen-containing silicone oil 5 parts, crosslinking agent 5 parts (including 4 parts of tetraethyl orthosilicate and 1 part of tetrabutyl titanate), 50 parts of silica sol (including 10 parts of alkaline silica sol, 40 parts of neutral silica sol) and 1000 parts of water.

[0089] In this embodiment, the method for preparing the concrete curing coating by using t...

Embodiment 2

[0102] In this embodiment, the specific components of the concrete curing agent are changed, and the preparation method of the concrete curing coating is the same as that in Embodiment 1, and will not be repeated here. The concrete curing agent of the present embodiment is made of hardener and hydrophobic agent, and by weight, the raw material of hardener comprises: 7 parts of fluorosilicates (wherein 3 parts of iron fluorosilicates, 4 parts of copper fluorosilicates) and water 100 parts; the raw materials of hydrophobic agent include: 10 parts of alkali catalyst (6 parts of potassium hydroxide, 2 parts of rubidium hydroxide, 2 parts of calcium hydroxide), 6 parts of silane coupling agent (of which N,N-diethyl- 4 parts of 3-aminopropyltrimethoxysilane, 3 parts of γ-aminopropylsilane triol), 6 parts of hydrogen-containing silicone oil, 7 parts of crosslinking agent (including 4 parts of tetramethyl orthosilicate, tetrapropyl titanate 3 parts of ester), 40 parts of silica sol (3...

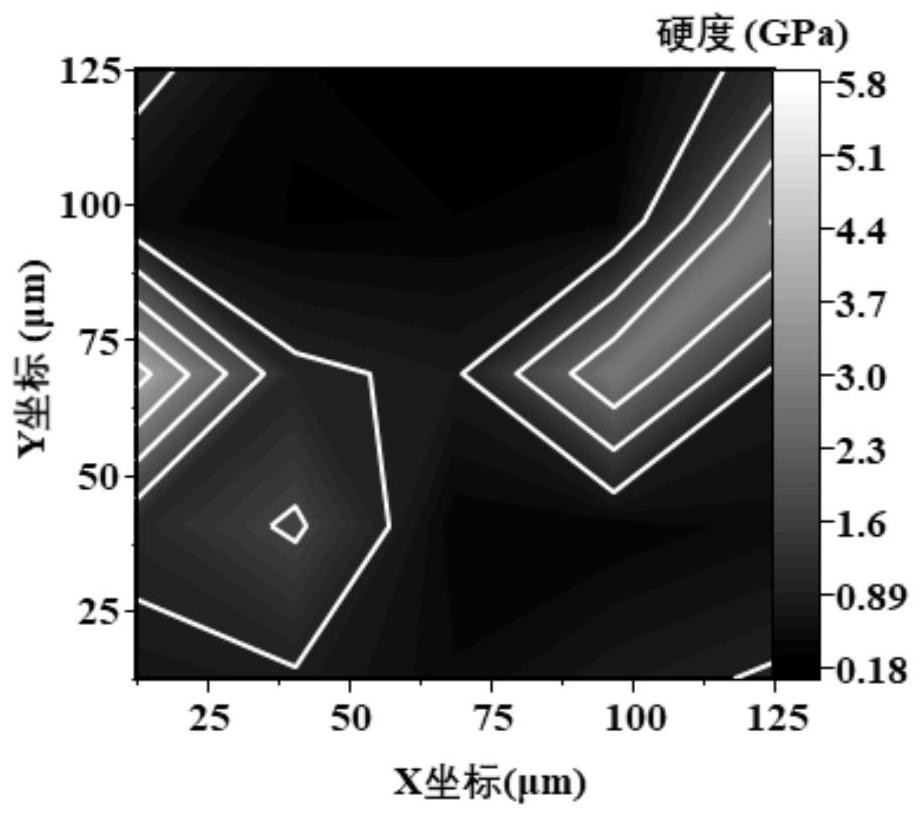

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com