MOFs derivative double-layer coated manganese ferrite wave-absorbing material as well as preparation method and application thereof

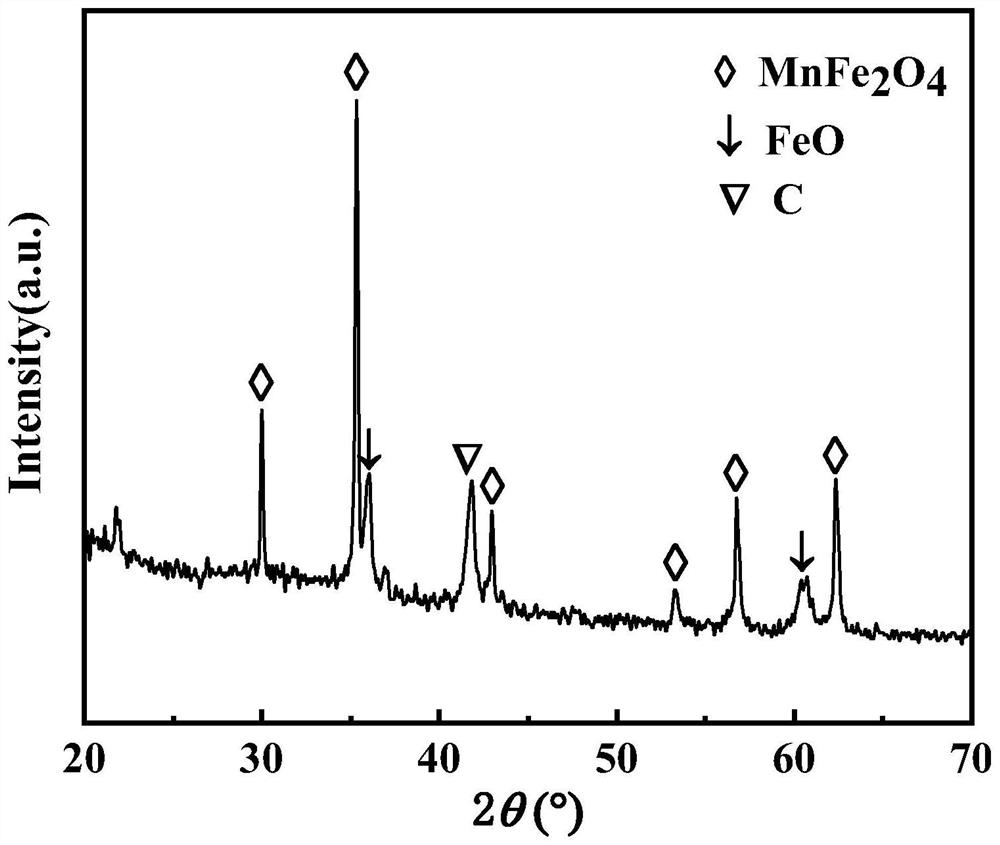

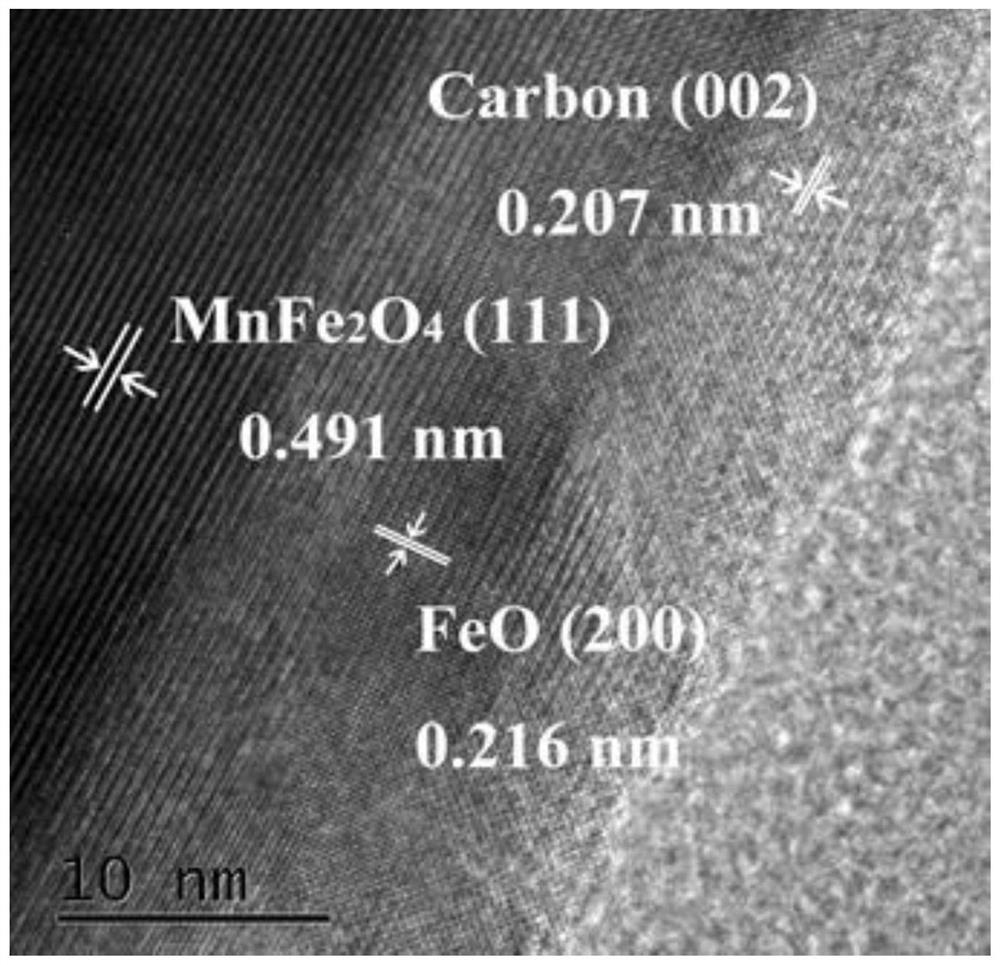

A wave-absorbing material, manganese ferrite technology, applied in the field of MOFs derivative double-coated manganese ferrite wave-absorbing material and its preparation, can solve the problem of difficult to achieve effective absorption of electromagnetic waves, poor mechanical properties, corrosion resistance Poor performance and other problems, achieve good chemical stability and composite characteristics, increase the complex dielectric constant, and broaden the absorption frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

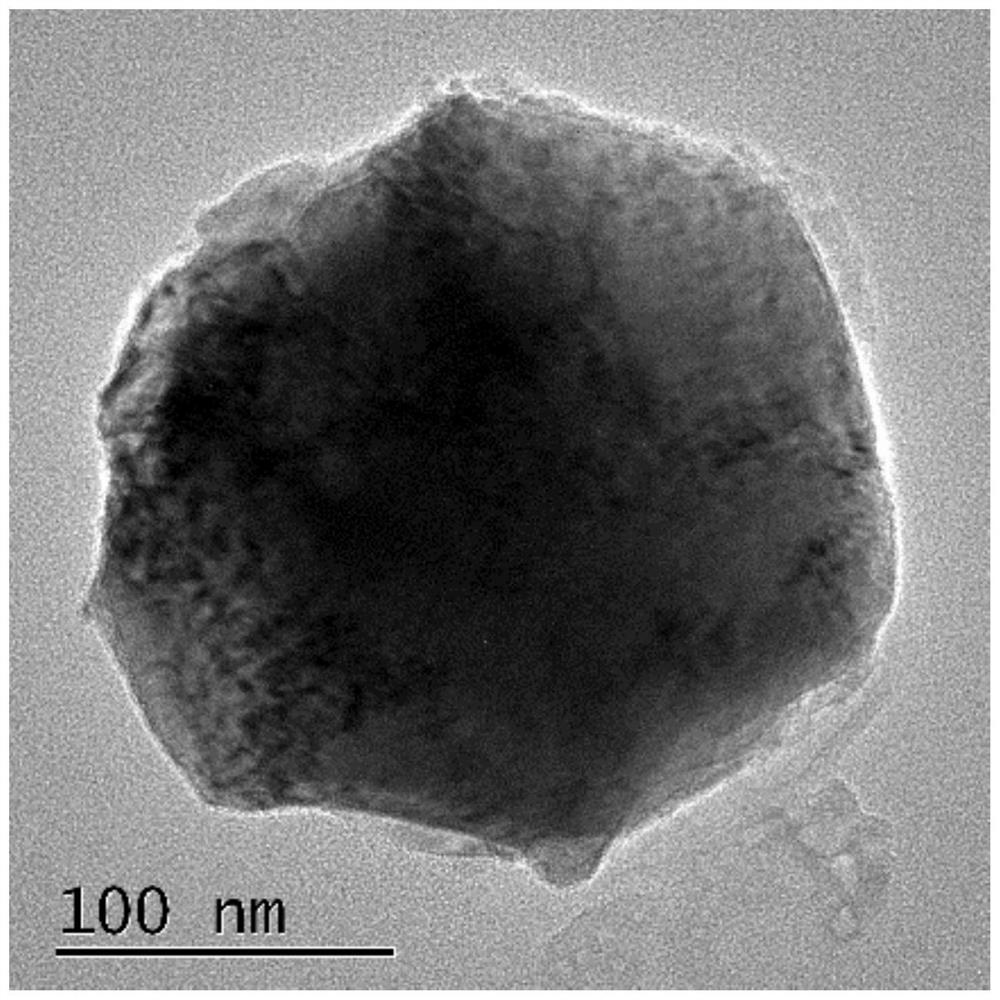

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: ZIF-8 (the unit molecular formula of ZIF-8 is C 8 h 10 N 4 Preparation of Zn) derivative double-layer coated manganese ferrite absorbing material:

[0041] (1) Formulation:

[0042] 85wt.%MnFe 2 o 4 , 15wt.% ZIF-8 (wt.% is mass percentage)

[0043] (2) Preparation process:

[0044] Step 1, 3.60 g FeCl 3 ·6H 2 O and 1.32 g MnCl 2 4H 2 O is fully dissolved in 160ml of ethylene glycol, stirred evenly at room temperature to form a solution A; add 14.4g sodium acetate and 4.0 g polyethylene glycol to the A solution to form a B solution, and use HJ-6 magnetic heating and stirring Stir for 30 minutes; transfer solution B to 100ml polytetrafluoroethylene lining, then put the polytetrafluoroethylene lining with solution B into a stainless steel reaction kettle, tighten the seal, and place it in an oven for hydrothermal reaction , the reaction temperature is 200° C., and the time is 12 hours. Cool down to the greenhouse with the furnace, and centrifuge a...

Embodiment 2

[0048] Embodiment 2: ZIF-8 (the unit molecular formula of ZIF-8 is C 8 h 10 N 4 Preparation of Zn) derivative double-layer coated manganese ferrite absorbing material:

[0049] (1) Formulation:

[0050] 80wt.%MnFe 2 o 4 , 20wt.% ZIF-8 (wt.% is mass percentage)

[0051] (2) Preparation process:

[0052] The difference between embodiment 2 and embodiment 1 is that the Zn(NO 3 ) 2 ·6H 2 O was adjusted to 0.65g, dimethylimidazole was adjusted to 1.08g, and other steps were the same as in Example 1.

Embodiment 3

[0053] Embodiment 3: ZIF-67 (the unit molecular formula of ZIF-67 is C 4 h 6 N 2 Preparation of Co) derivative double-layer coated manganese ferrite absorbing material:

[0054] (1) Formulation:

[0055] 85wt.%MnFe 2 o 4 , 15wt.% ZIF-67 (wt.% is mass percentage)

[0056] (2) Preparation process:

[0057] The difference between Example 3 and Example 1 is that the metal organic framework material prepared in this example is ZIF-67, and the unit molecular formula is C 4 h 6 N 2 Co, in step 3, Zn(NO 3 ) 2 ·6H 2 O was replaced by Co(NO 3 ) 2 ·6H 2 O, quality is 0.45g, other steps are all identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com