Basalt nanosheet and preparation method thereof

A technology of basalt and nanosheets, applied in nanotechnology, silicate, grain processing, etc., to achieve the effect of avoiding process, excellent dielectric properties and chemical resistance, and simple and effective methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of basalt nanosheets, comprising the following steps:

[0037](1) Surface etching of basalt scales: Weigh a certain amount of basalt scales and place them in a three-neck flask, add hydrochloric acid solution (HCl) to it, and the dosage ratio of basalt scales and hydrochloric acid solution (HCl) is 0.4g: 30mL , the concentration of the hydrochloric acid solution was 4moL / L, and mechanically stirred at a stirring rate of 1000rpm for 12h under the condition of a water bath at 25°C for surface etching reaction. After the reaction, filter and wash to neutrality (pH test paper test), and dry in an oven at 60°C for 12 hours to obtain preliminary surface-etched basalt scales.

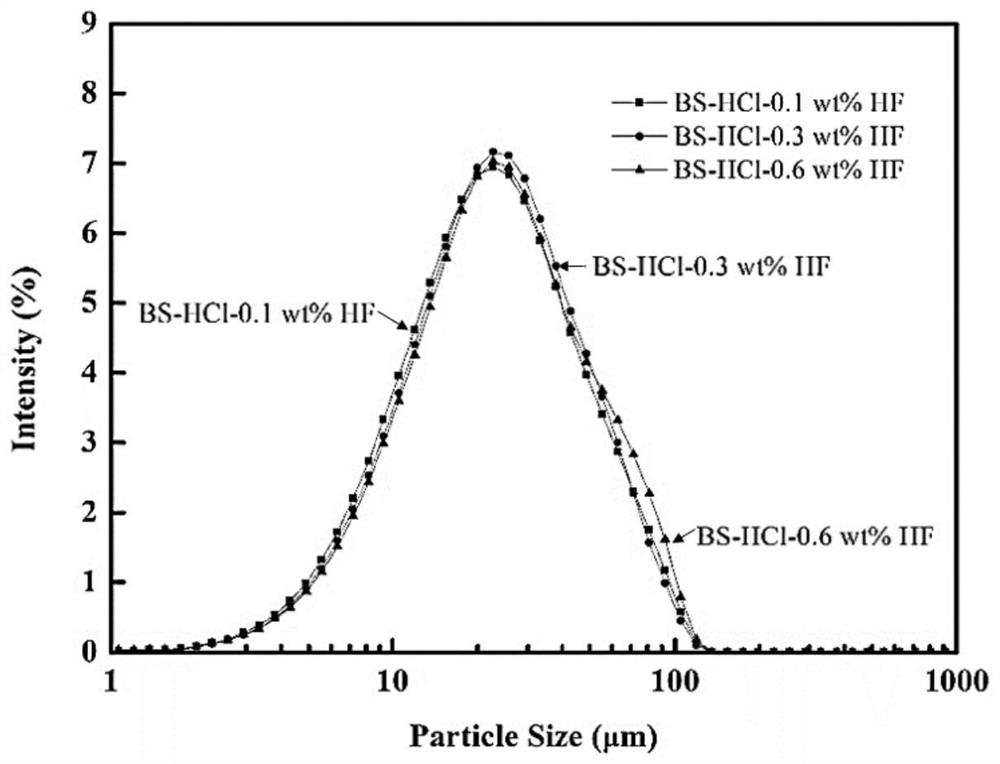

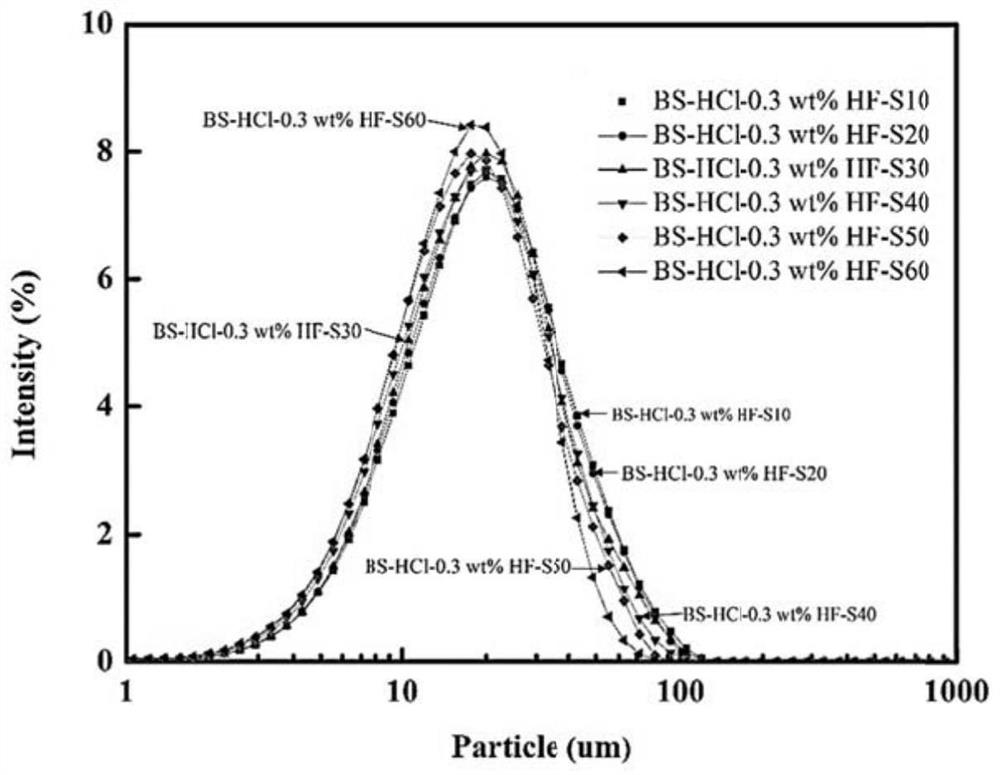

[0038] (2) Depth etching of basalt scales: take a certain amount of preliminary surface etched basalt scales and place them in a three-neck flask, add a configured HF solution with a mass fraction of 1.5wt% therein, and initially surface etched basalt scales The dosage ratio of bas...

Embodiment 2

[0042] A preparation method of basalt nanosheets, comprising the following steps:

[0043] (1) Surface etching of basalt scales: Weigh a certain amount of basalt scales and place them in a three-neck flask, add hydrochloric acid solution (HCl) to it, and the dosage ratio of basalt scales and hydrochloric acid solution (HCl) is 0.4g: 30mL , the concentration of hydrochloric acid solution is 4moL / L, and the stirring speed is 500rpm under the condition of 25°C water bath, and the surface etching reaction is carried out by mechanical stirring for 6h. After the reaction, filter and wash to neutrality (pH test paper test), and dry in an oven at 60°C for 12 hours to obtain preliminary surface-etched basalt scales.

[0044] (2) Depth etching of basalt scales: Weigh a certain amount of preliminary surface-etched basalt scales and place them in a three-necked flask, add a configured HF solution with a mass fraction of 0.1wt% therein, and initially surface-etch basalt scales. The dosage...

Embodiment 3

[0048] A preparation method of basalt nanosheets, comprising the following steps:

[0049] (1) Surface etching of basalt scales: Weigh a certain amount of basalt scales and place them in a three-neck flask, add hydrochloric acid solution (HCl) to it, and the dosage ratio of basalt scales and hydrochloric acid solution (HCl) is 0.4g: 30mL , the concentration of the hydrochloric acid solution was 4moL / L, and mechanically stirred at a stirring rate of 1500rpm under the condition of a 60°C water bath for 24h to carry out the surface etching reaction. After the reaction, filter and wash to neutrality (pH test paper test), and dry in an oven at 60°C for 12 hours to obtain preliminary surface-etched basalt scales.

[0050] (2) Depth etching of basalt scales: Weigh a certain amount of preliminary surface-etched basalt scales and place them in a three-neck flask, add a configured HF solution with a mass fraction of 0.6 wt% therein, and initially surface-etch basalt scales. The dosage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com