Machine tool chip removal and cleaning device for numerical control machine tool

A technology for CNC machine tools and cleaning devices, which is applied to metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc. Easy to adjust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

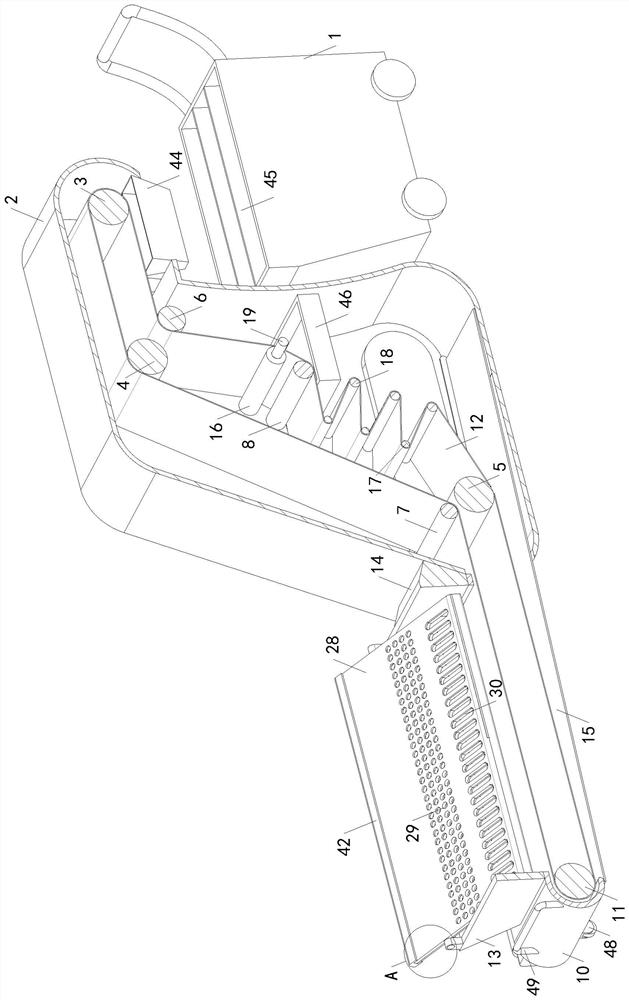

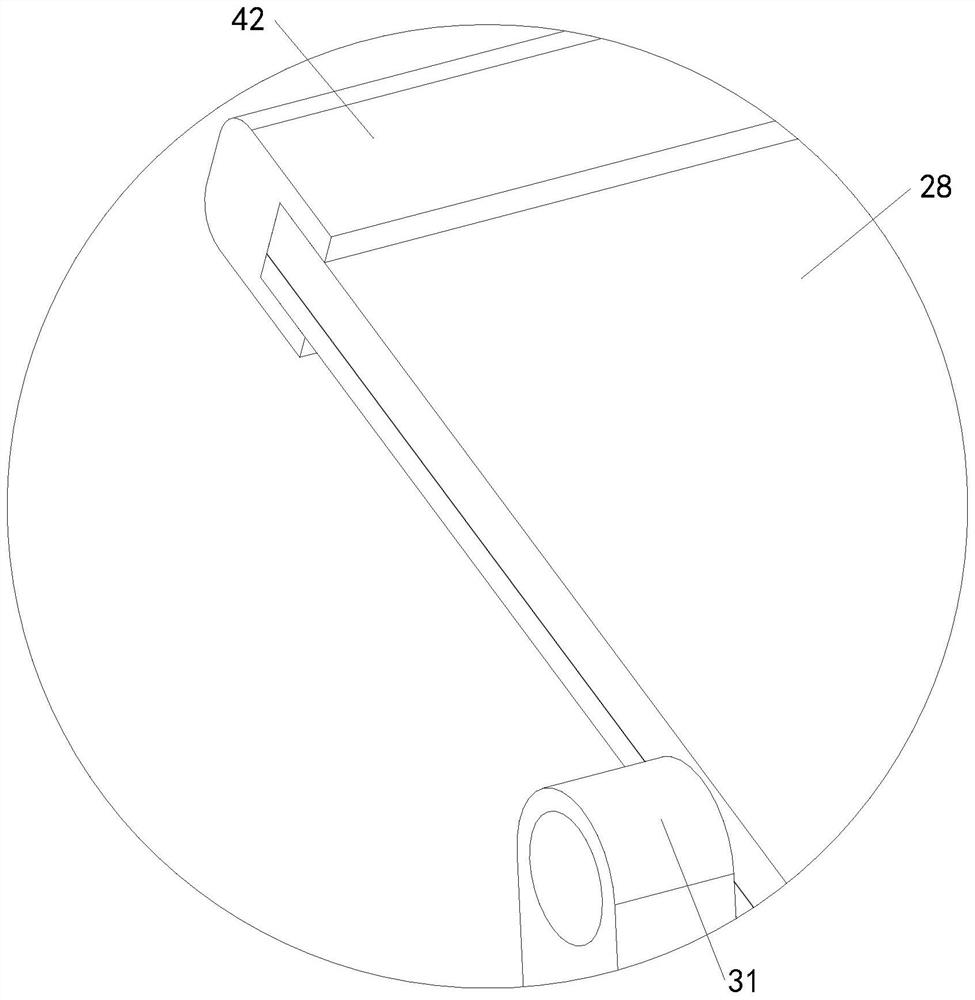

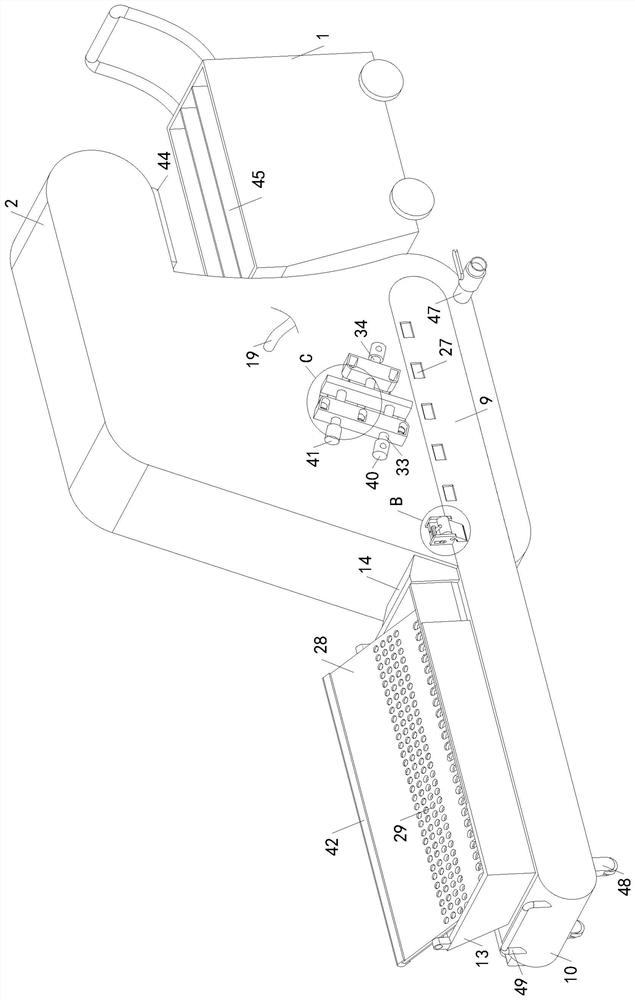

[0033] see Figure 1-8, a machine tool chip removal and cleaning device for a numerically controlled machine tool, comprising a chip collecting vehicle 1 and a main frame 2, the chip collecting vehicle 1 is located at a corresponding position on the lower right of the main frame 2, and the main frame 2 is communicated with a recovery drain pipe 47 , the on-off valve is installed on the recovery discharge pipe 47, which can control the on-off of the recovery discharge pipe 47, so as to facilitate the discharge of the recovered cutting fluid. The main body frame 2 is provided with a discharge port, which is located at Directly above the chip collecting vehicle 1, a plurality of distributing barrels 44 are arranged in the main body frame 2 at the discharge port, and a partition plate 45 is arranged in the chip collecting vehicle 1 to facilitate the classified discharge and collection of waste chips. The main body frame 2 The inner rotation is connected with the first driving roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com