Preparation method and application of modified activated carbon with ultrahigh formaldehyde adsorption capacity

A formaldehyde adsorption and activated carbon technology, applied in the field of materials, can solve the problems of high cost of silver ion catalysts, and achieve the effects of facilitating large-scale production, increasing the reaction rate and limit, and making materials easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

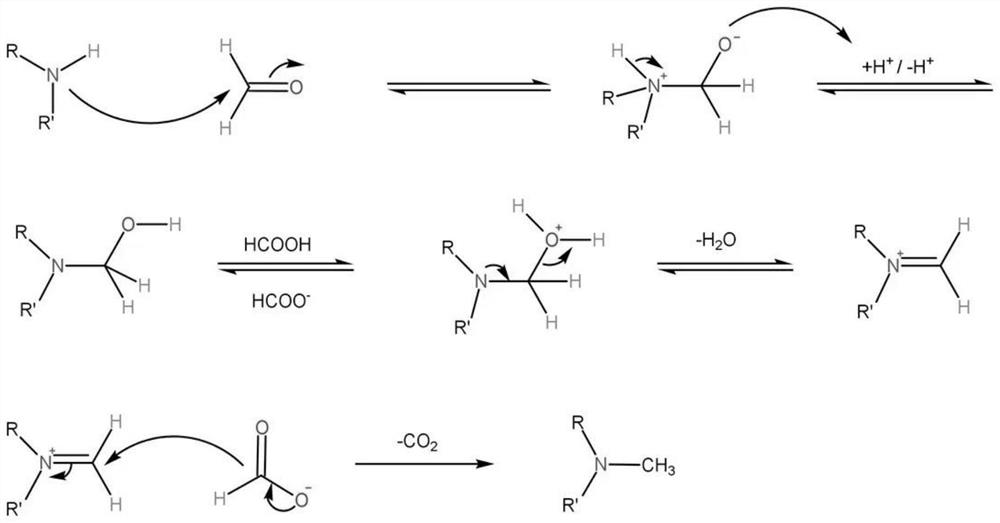

[0031] Embodiment 1 preparation

[0032] (1) Preparation of modified activated carbon with ultra-high formaldehyde adsorption capacity

[0033] 1) Dissolve 2.5 g of polyethyleneimine with a relative molecular mass of 600 and 0.5 g of urea crystals in 50 mL of distilled water, stir for 0.5 h, and mix well to obtain a mixed solution A;

[0034] 2) Heating the mixed solution A obtained in step 1) at 50° C. while stirring for 2 hours, and stirring evenly to obtain the mixed solution B;

[0035] 3) Wrap activated carbon in aluminum foil, put it into a muffle furnace and heat at 400°C for 8 hours;

[0036] 4) Add the activated carbon obtained in step 3) to the mixed solution B obtained in step 2), and continue stirring for 3d to obtain mixed solution C;

[0037] 5) Filter the solution obtained in step 4), and dry in an oven at 180° C. for 12 hours in an air environment to obtain modified activated carbon.

[0038] (2) Preparation of activated carbon with polyethyleneimine attache...

Embodiment 2

[0044] Example 2 application

[0045] 1) Roll 5 layers of medical degreasing gauze (length 17cm, width 5cm) on a glass rod (glass rod specification: length 30cm, diameter 5mm), and fix it with cotton thread;

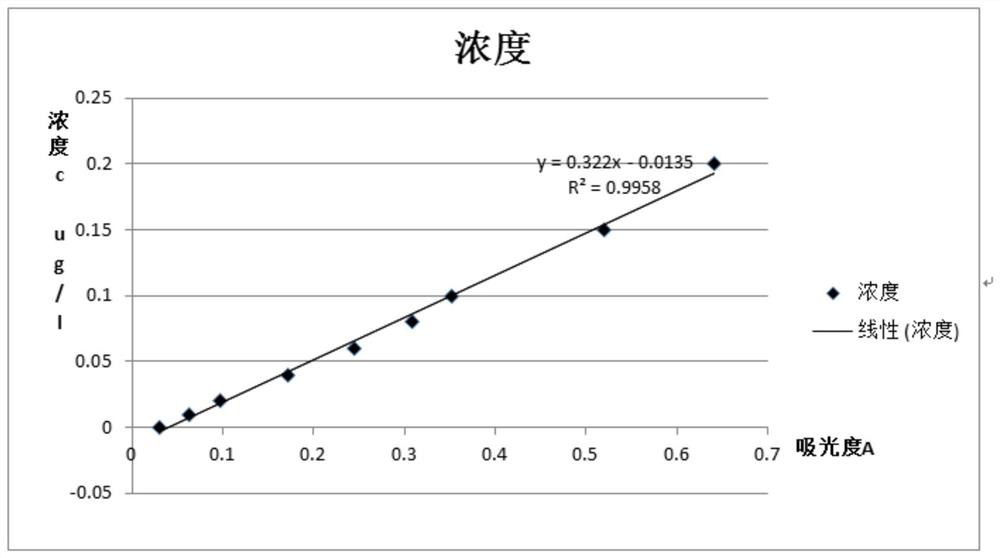

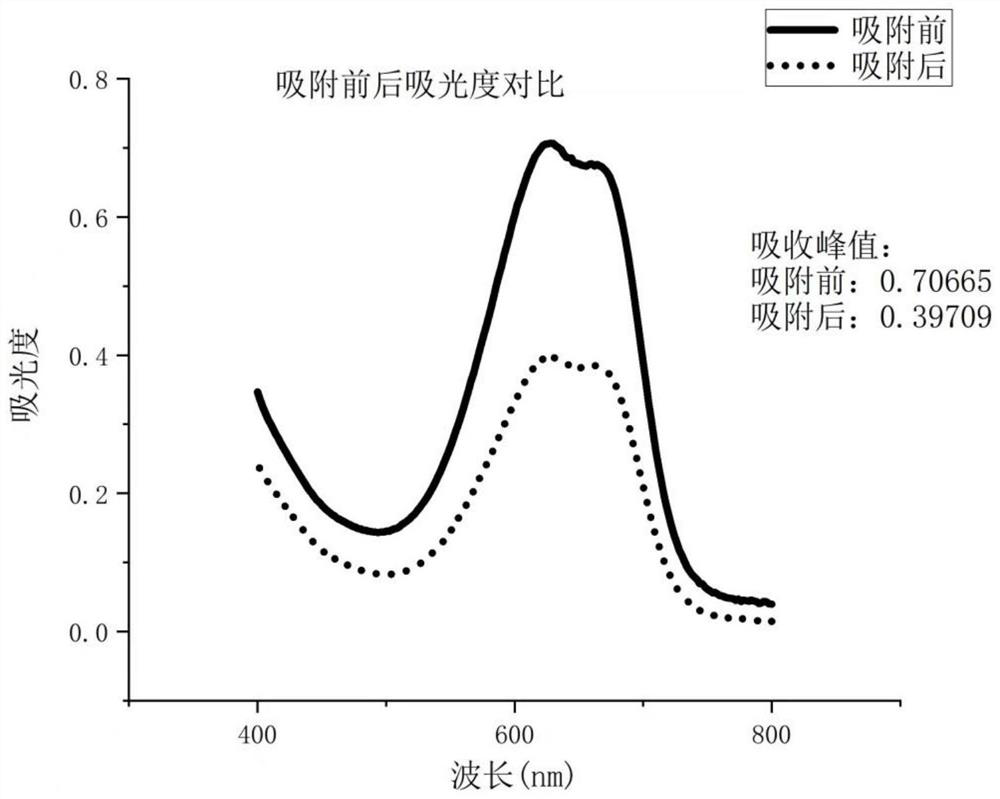

[0046] 2) Take 0.2mL of formaldehyde solution with a mass fraction of 0.2%, drop it on the gauze wrapped on the glass rod, and immediately put it into a volume of 1.6m 3 In the air chamber, turn on the electric fan in the air chamber, weigh 5g of the modified activated carbon prepared in Example 1 (1), spread it evenly in a circular petri dish, put it in the air chamber, and use it before and after 18h. Formaldehyde spectrophotometry was used to measure the concentration change of formaldehyde in the two air chambers.

[0047] 3) Weigh 5g of activated carbon and the activated carbon with only polyethyleneimine attached and the activated carbon with urea attached only prepared in Example 1, and carry out the application experiment according to the steps 1)-2) of Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com