Nanometer composite conductive film and preparation method thereof

A conductive film and nanocomposite technology, which is applied in the equipment for manufacturing conductive/semiconductor layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve the drying effect of single structure and nanocomposite conductive film materials It can improve the effect, save drying time and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

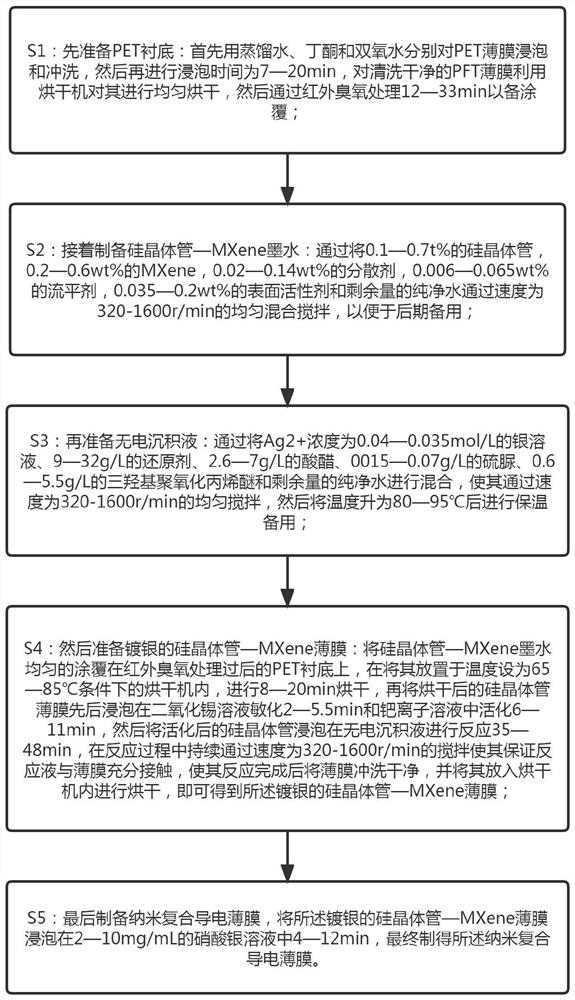

[0035] Such as Figure 1 to Figure 8 Shown, the preparation method of a kind of nanocomposite conductive thin film of the present invention, this preparation method comprises the following steps:

[0036] S1: Prepare the PET substrate first: first soak and rinse the PET film with distilled water, methyl ethyl ketone and hydrogen peroxide respectively, and then soak for 13 minutes. Dry the cleaned PFT film evenly with a dryer, and then Treated with infrared ozone for 20 minutes to prepare for coating;

[0037] S2: Next prepare the silicon transistor—MXene ink: by adding 0.45% silicon transistor, 0.4wt% MXene, 0.07wt% dispersant, 0.0063wt% leveling agent, 0.015wt% surfactant and the remaining amount of Purified water is uniformly mixed and stirred at a speed of 950r / min for later use;

[0038] S3: Prepare the electroless deposition solution again: by adding Ag 2+ Silver solution with a concentration of 0.15mol / L, 18g / L reducing agent, 3.5g / L acid ester, 0.02g / L thiourea, 3g / L...

Embodiment approach

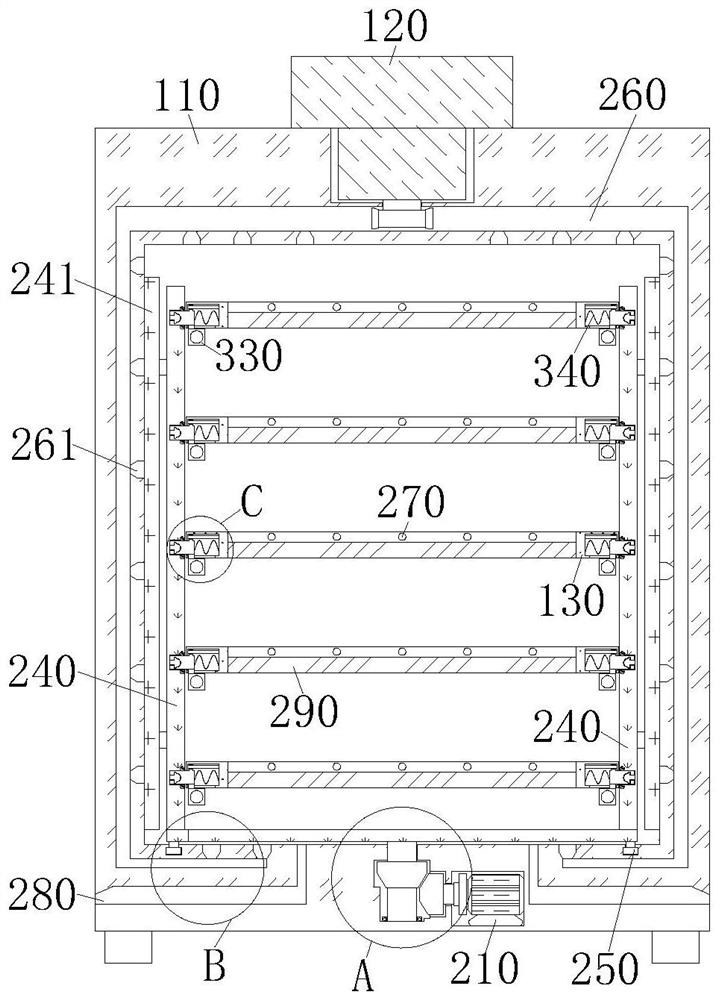

[0046] As an embodiment of the present invention, in S1 and S4, the dryer includes a dryer body 110, a dryer 120 and a fixing plate 130, and multiple sets of fixing plates 130 are arranged inside the dryer body 110, so The dryer 120 is installed on the upper end of the dryer body 110, and the inside of the dryer body 110 is provided with a rotating mechanism, the rotating mechanism includes a motor 210, a rotating shaft 220, a fixing frame 240 and a filter plate 290, and the motor 210 is installed Inside the lower end of the drying machine body 110, the rotating shaft 220 is movably installed inside the lower end of the drying machine body 110 through bearings, and a driving assembly 230 is arranged between the lower end of the rotating shaft 220 and the output shaft of the motor 210. The bottom end of 240 is fixedly connected to the top of the rotating shaft 220, the fixed frame 240 is movably installed inside the dryer body 110 through the support assembly 250, the filter pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com