A kind of non-hard rock coring bit and its processing technology

A technology for coring bits and bits, which is used in drill bits, earth-moving drilling, drilling equipment, etc., can solve the problems of inability to drill, increase drilling costs, and large core disturbance, reduce collapse and mud drilling, and reduce frequent replacement. , the effect of addressing adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

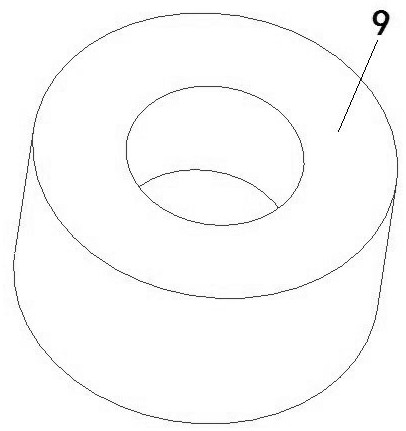

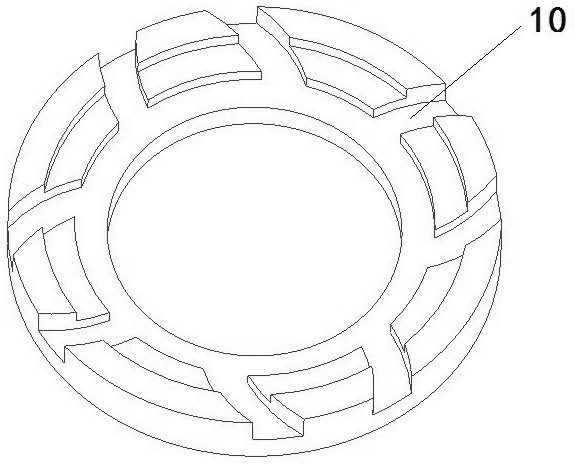

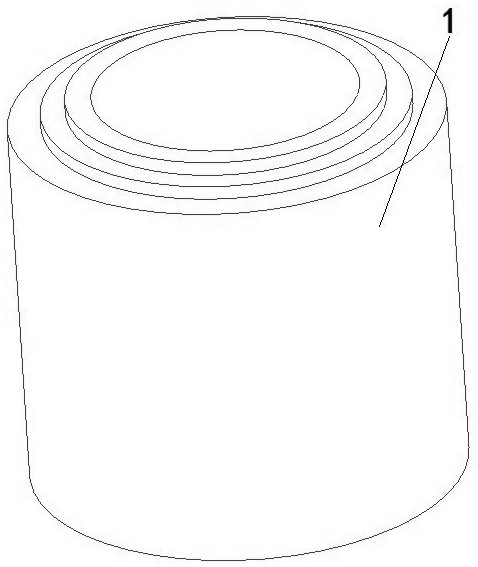

[0029] A non-hard rock coring drill bit, the nozzle at the end of the drill steel body 1 is divided into a positive nozzle 4 and a reverse nozzle 5, the positive nozzle 4 and the reverse nozzle 5 are spiral nozzles, that is, the nozzle is from the inner cavity of the drill steel body 1 to the The outer circumference of the drill bit steel body 1 forms an arc channel; the helical direction of the arc channel of the positive nozzle 4 is opposite to the direction of rotation of the drill bit steel body 1, and the helical direction of the arc channel of the reverse water outlet 5 is the same as that of the drill bit steel body. The rotation direction of the body 1 is the same; the positive water port 4 and the reverse water port 5 are alternately arranged at the end of the drill bit steel body 1, and the protrusion between the adjacent positive water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com